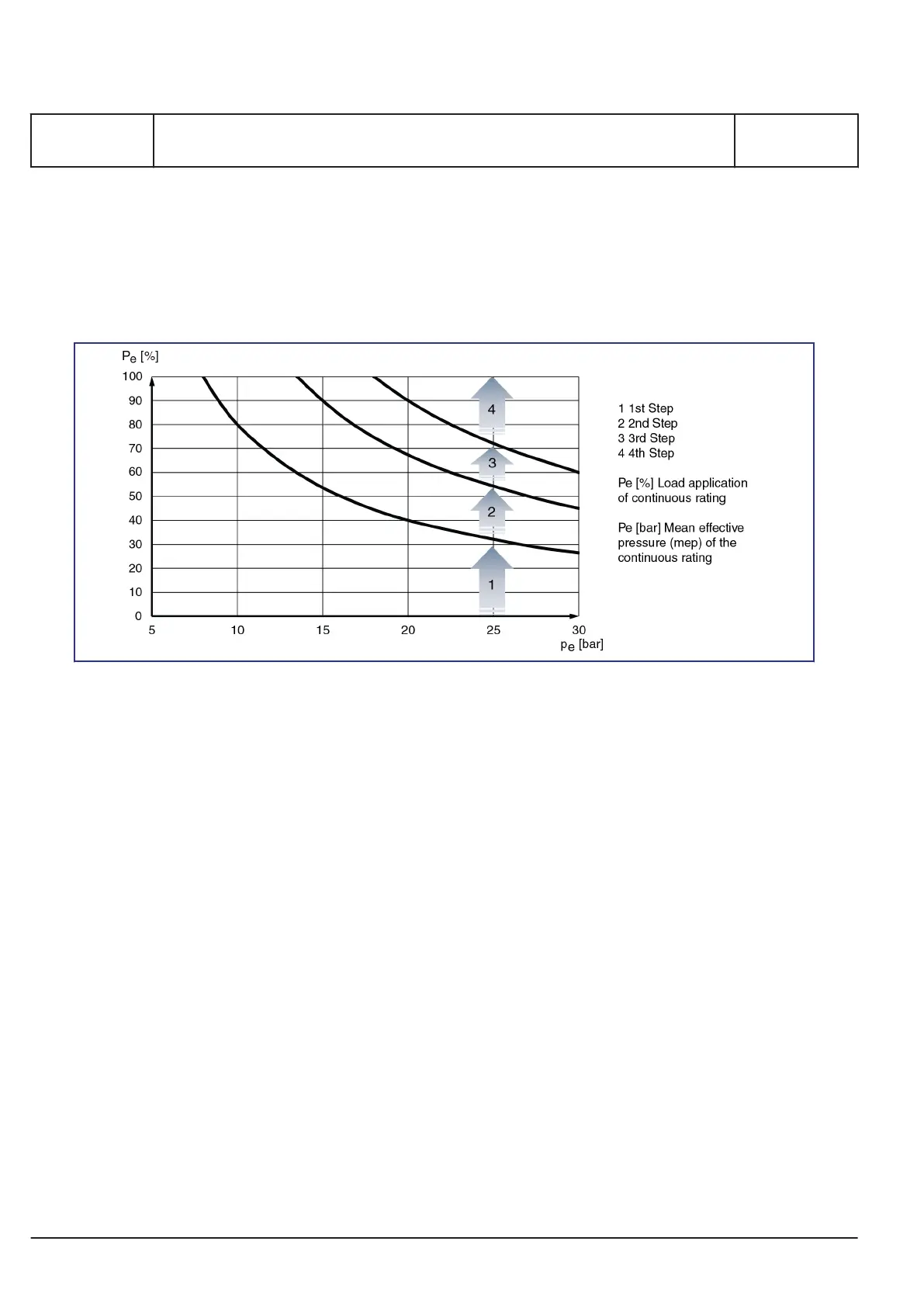

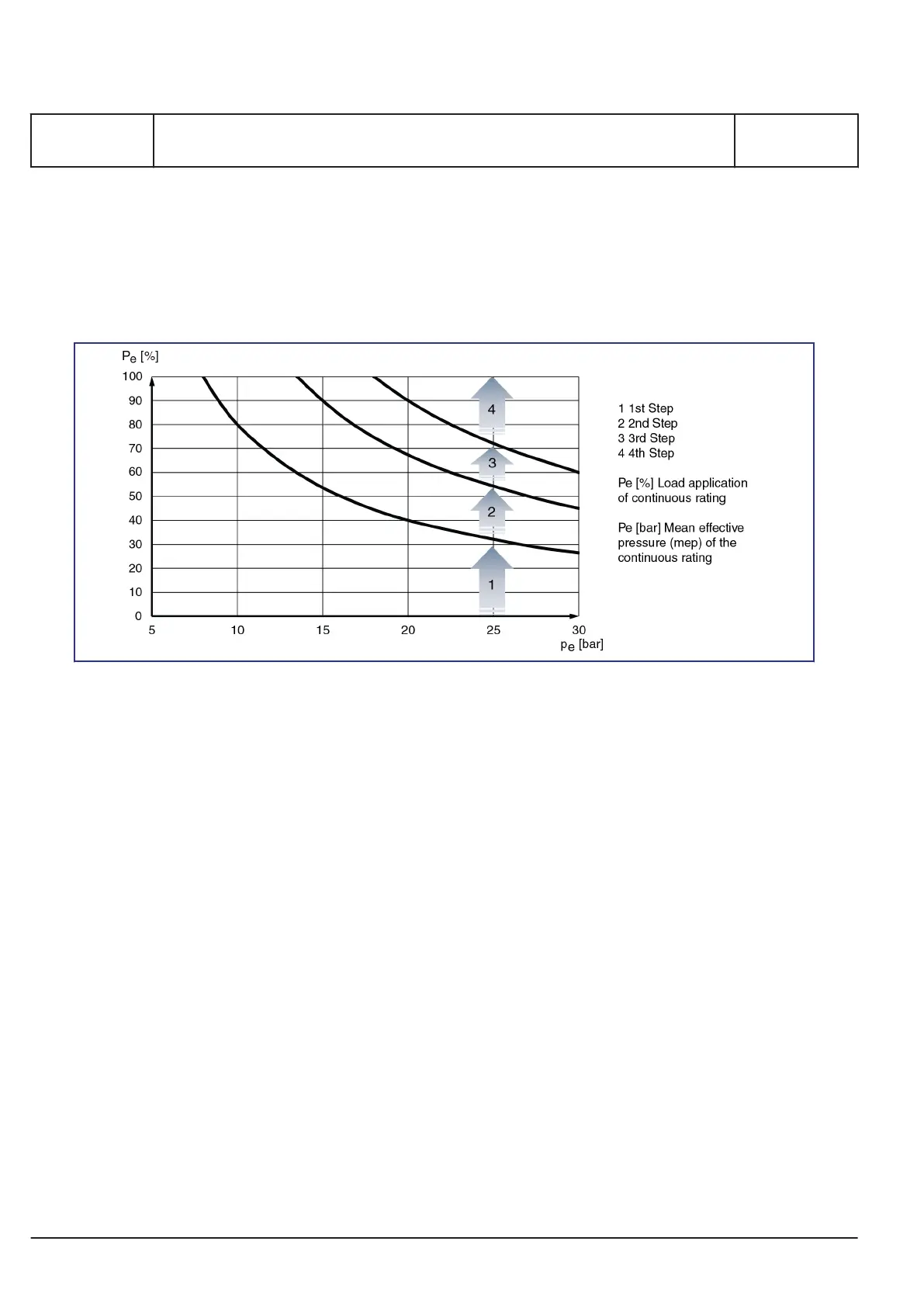

For applications from 0 % to 100 % continuous rating, according to IACS and ISO 8528-5, the following dia-

gram is applied:

Fig. 1 Load application in steps as per IACS and ISO 8528-5.

According to the diagram in Fig. 1 the maximum allowable load application steps are defined in the table

below. (24.4 bar mean effective pressure has been determined as a mean value for the listed engine types.)

Note: Our small bore GenSets has normally a better load responce than required by IACS and therefore a

standard load responce test where three load steps (3 x 33%) is applied will be demostrated at factory accept-

ance test.

Minimum requirements concerning dynamic speed drop, remaining speed variation and recovery time during

load application are listed below.

In case of a load drop of 100 % nominal engine power, the dynamical speed variation must not exceed 10 %

of the nominal speed and the remaining speed variation must not surpass 5 % of the nominal speed.

MAN Diesel & Turbo

B 21 01 1

Shop test programme for power plants

1699986-3.2

Page 2 (4)

V28/32H, V28/32S, L28/32S, L27/38S, L23/30S, L21/31S, L16/24S

2016.03.17

Loading...

Loading...