Âp

2000H - PERIODIC MAINTENANCE - EVERY 2000 HOURS OF SERVICE OR 4 YEARS

ALSO PERFORM THE 500 HOUR AND 1000 HOUR PERIODIC MAINTENANCE OPERATIONS.

CHECK Wheel nut tightening torques

- Check the condition of the tyres, to detect cuts, blisters, wear, etc.

- Check the tightening torque of the wheel nuts with a torque wrench.

• Front wheels: 550 N.m ± 55 N.m

• Rear wheels: 110 N.m ± 16 N.m

MC18-2

• Rear wheels: 200 N.m ± 20 N.m

MC18-4

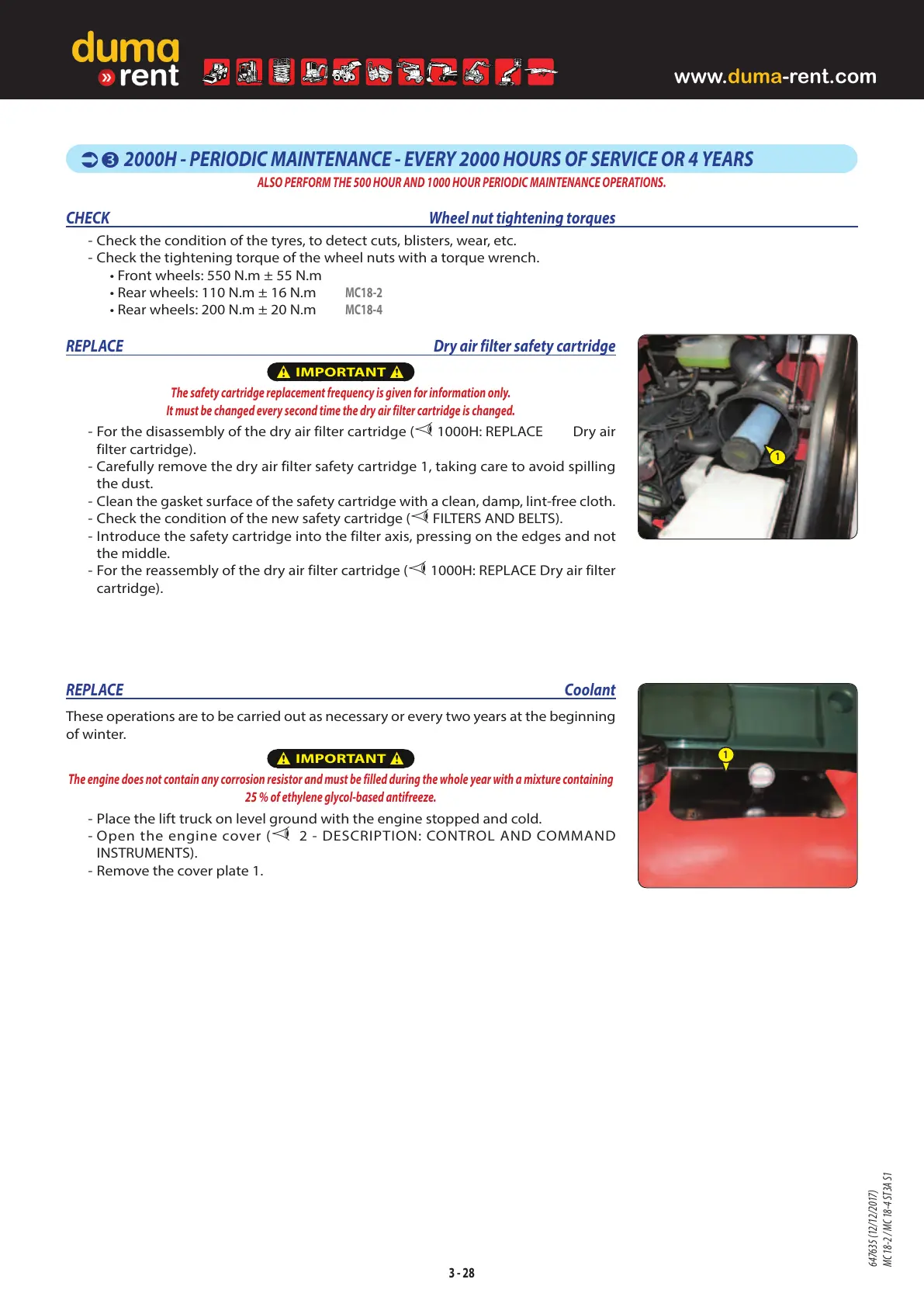

REPLACE Dry air filter safety cartridge

IMPORTANT

The safety cartridge replacement frequency is given for information only.

It must be changed every second time the dry air filter cartridge is changed.

- For the disassembly of the dry air filter cartridge ( 1000H: REPLACE Dry air

filter cartridge).

- Carefully remove the dry air filter safety cartridge 1, taking care to avoid spilling

the dust.

- Clean the gasket surface of the safety cartridge with a clean, damp, lint-free cloth.

- Check the condition of the new safety cartridge ( FILTERS AND BELTS).

- Introduce the safety cartridge into the filter axis, pressing on the edges and not

the middle.

- For the reassembly of the dry air filter cartridge (

1000H: REPLACE Dry air filter

cartridge).

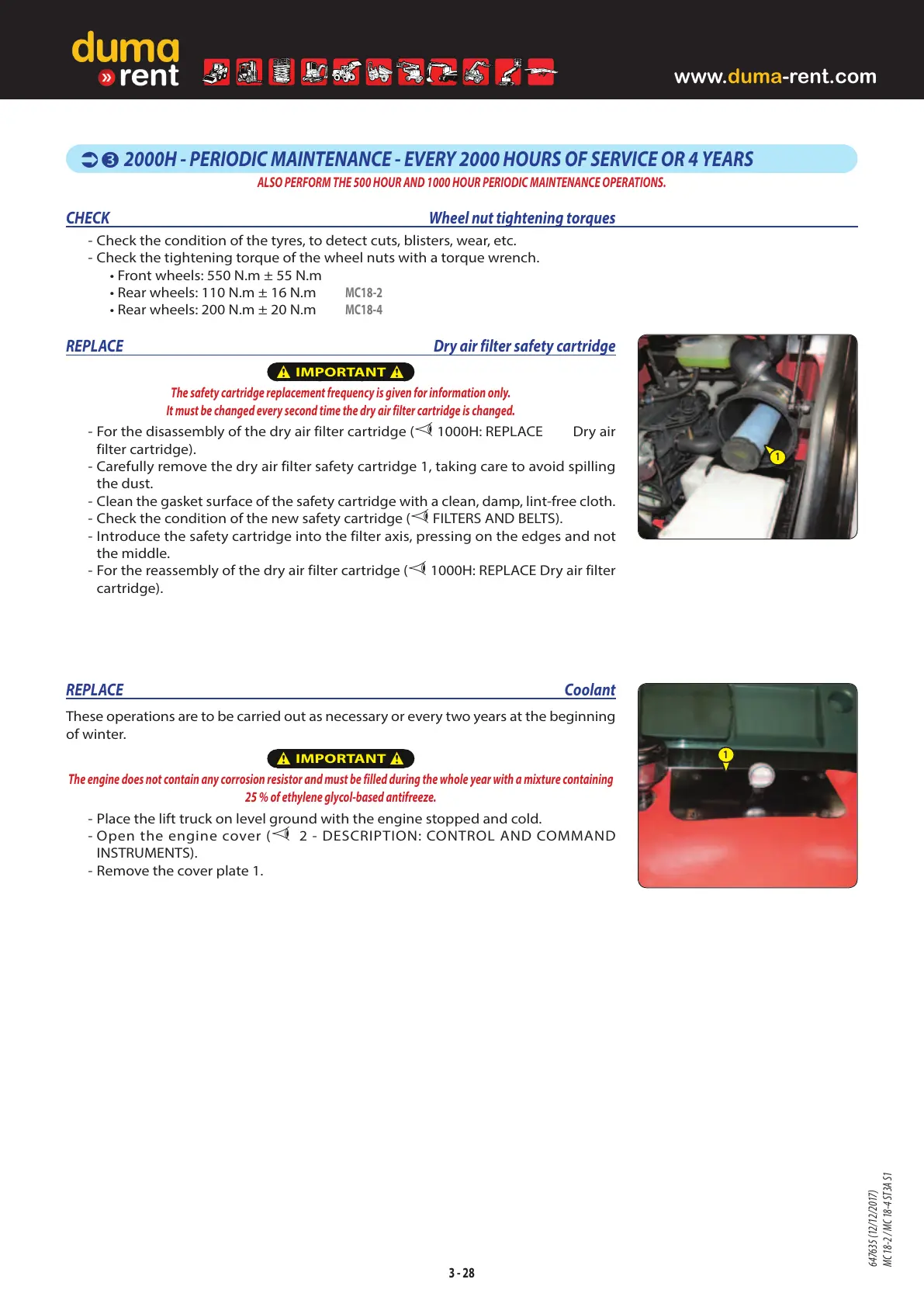

REPLACE Coolant

These operations are to be carried out as necessary or every two years at the beginning

of winter.

IMPORTANT

The engine does not contain any corrosion resistor and must be filled during the whole year with a mixture containing

25 % of ethylene glycol-based antifreeze.

- Place the lift truck on level ground with the engine stopped and cold.

- Open the engine cover (

2 - DESCRIPTION: CONTROL AND COMMAND

INSTRUMENTS).

- Remove the cover plate 1.

1

1

3 - 28

647635 (12/12/2017)

Loading...

Loading...