3 - 20

D5 - CHANGE THE HYDRAULIC RETURN OIL FILTER

CARTRIDGE

D6 - CHANGE THE OIL TANK BREATHER

Thoroughly clean the outside of the filter and its surroundings before any

intervention in order to prevent any risk of polluting the hydraulic circuit.

- Lift up the overhead guard or the cabin (See chapter : INSTRUMENTS AND

CONTROLS in paragraph : 2 - DESCRIPTION).

- Unscrew the cover.

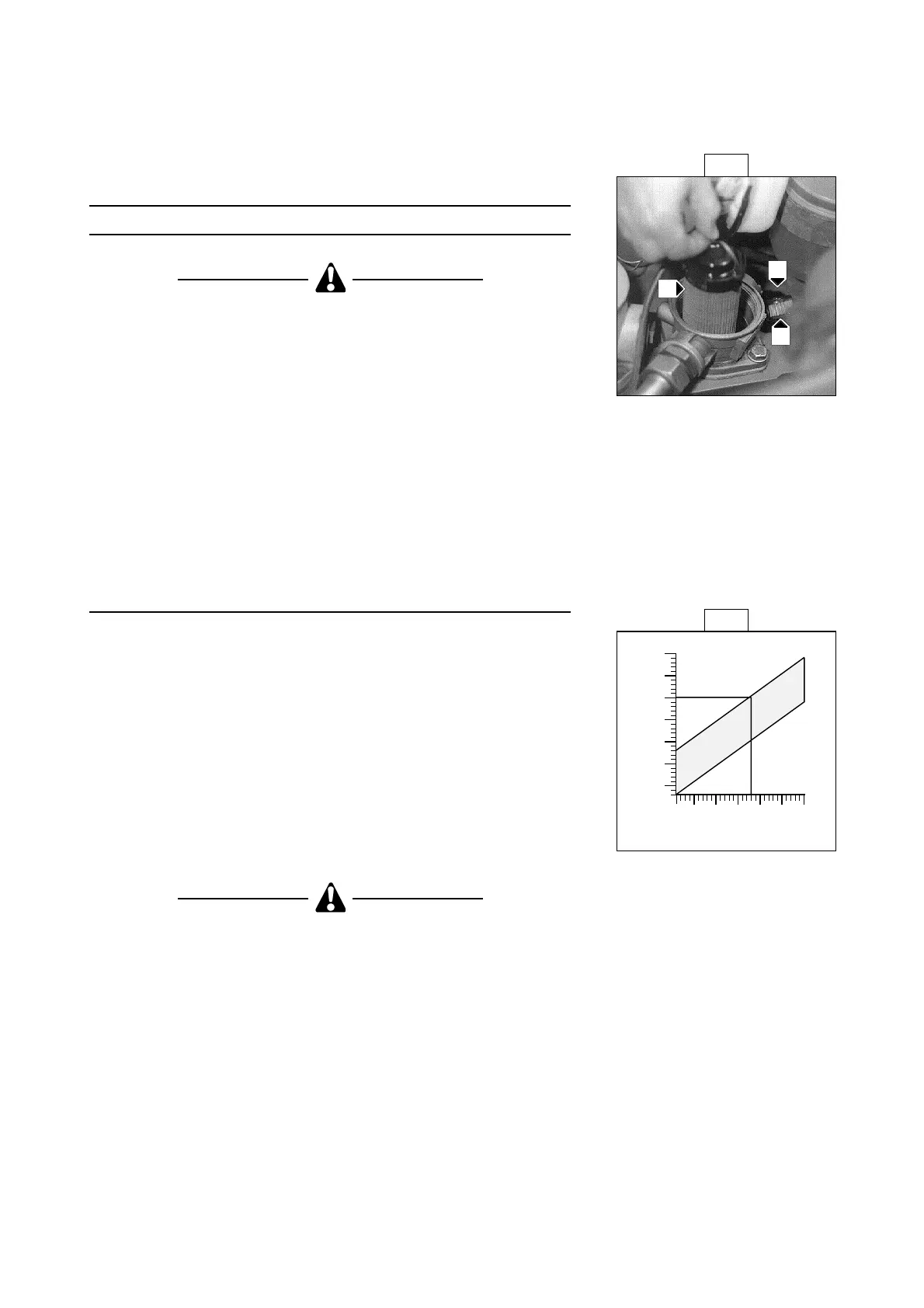

- Remove the hydraulic return oil filter cartridge 1 (Fig. D5) and replace it by a

new one.

-

Disassemble the cover 2 (Fig. D5) and change the oil tank breather 3

(Fig. D5).

- Ensure that the cartridge and the breather are correctly positioned and refit

the covers.

D7 - CH E C K TH E D E N S I T Y O F T H E B AT T E R Y

ELECTROLYTE

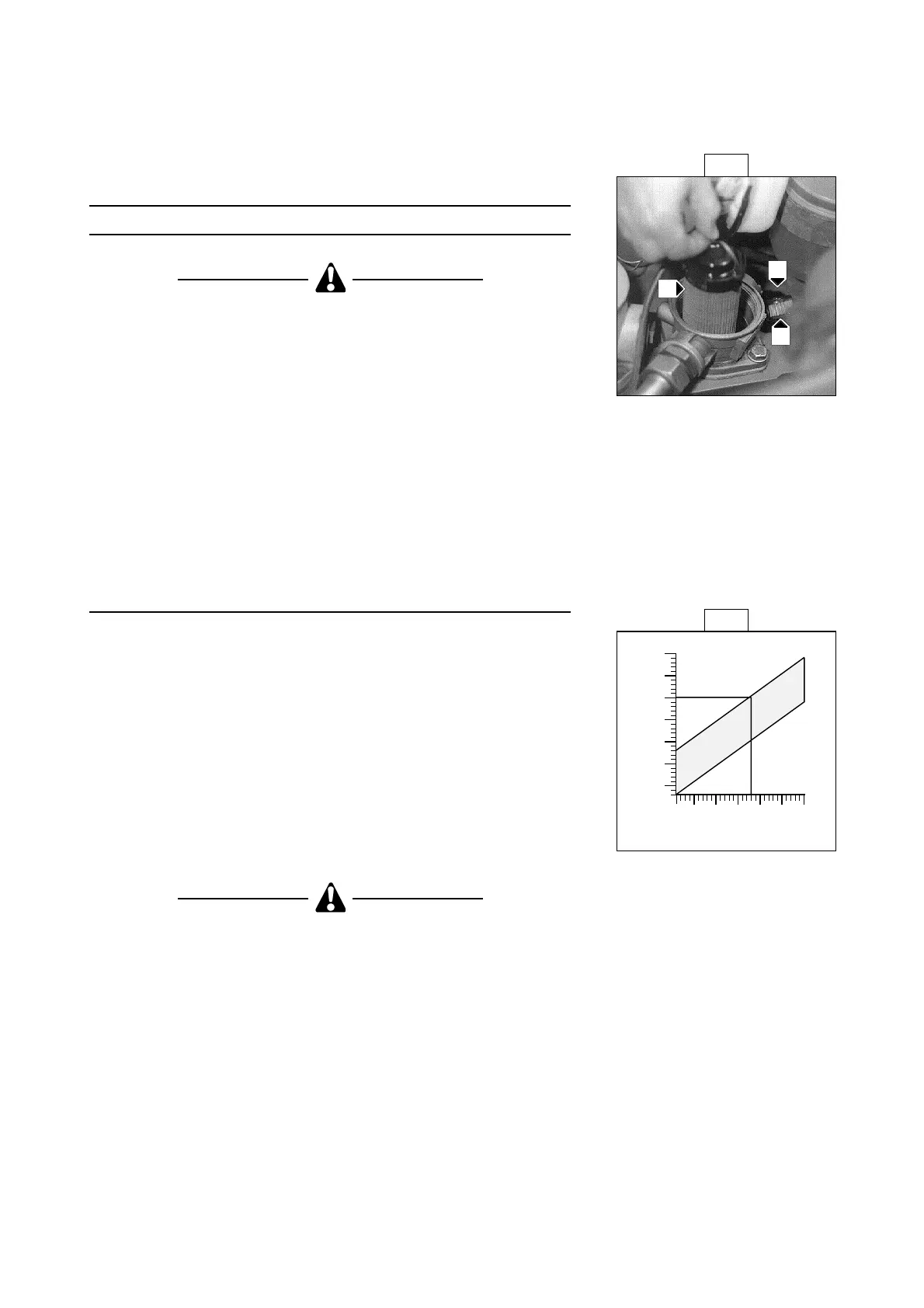

The electrolyte density varies depending on the temperature concerned, but a

minimum of 1260 at 16° C must be maintained.

In the shaded area (Fig. D7), the battery is in a normal charge condition.

Readings above this zone indicate that the battery needs to be recharged.

The density should not vary more than 0.025 units between cells.

- Lift up the overhead guard or the cabin (See chapter : INSTRUMENTS AND

CONTROLS in paragraph : 2 - DESCRIPTION).

- Check the electrolyte density in each battery cell using a hydrometer.

Do not carry out this check immediately after topping up with distilled water.

Recharge the battery for at least an hour before checking the battery

electrolyte density.

Handling and servicing a battery can be dangerous, take the following

precautions :

- Wear protective goggles.

- Keep the battery horizontal.

- Never smoke or work near a naked flame.

- Work in a well-ventilated area.

- In the event of electrolyte being spilled onto the skin or splashing in the

eyes, rinse thoroughly with cold water for 15 minutes and call a doctor.

D7

1.240

1.250

1.260

1.270

1.280

1.290

1.300

-10

14

-18

0

°C

°F

0

32

10

50

20

68

30

86

40

104

Loading...

Loading...