3-19

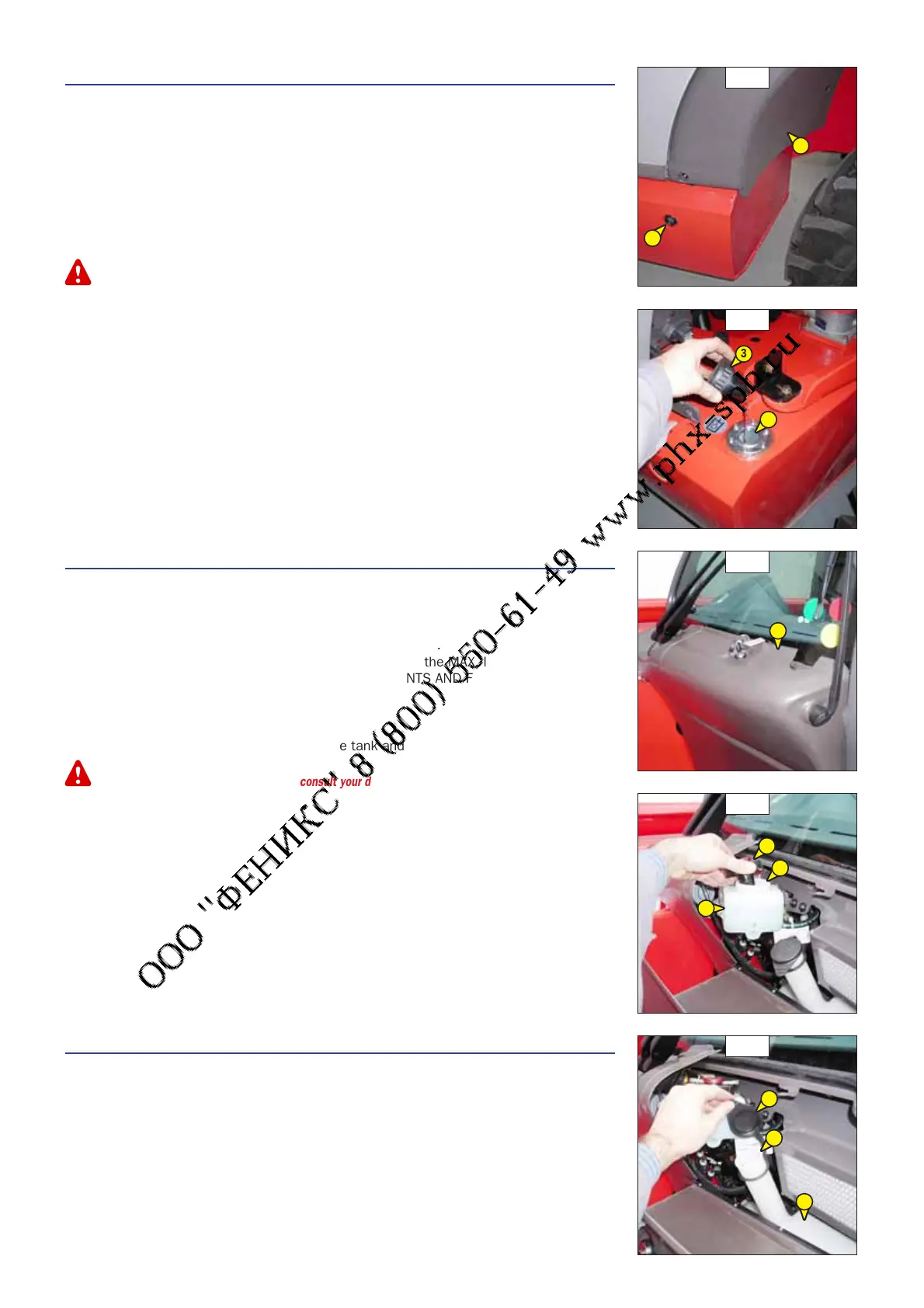

B6 - HYDRAULIC OIL LEVEL

CHECK

Place the lift truck on level ground with the I.C. engine stopped, and the jib retracted and

lowered as far as possible.

- Check dipstick 1 (fig. B6/1). The correct level must stand at the level of the red point.

- If necessary, add oil (see: 3 - MAINTENANCE: LUBRICANTS AND FUEL).

- Lift up protective casing 2 (fig. B6/1).

- Remove cap 3 (fig. B6/2).

- Add oil by filler port 4 (fig. B6/2).

Use a clean funnel and clean the underside of the oil drum before filling.

- Put the cap back.

- Check visually that there is no leakage in the tank and pipes.

- Refit the protective casing.

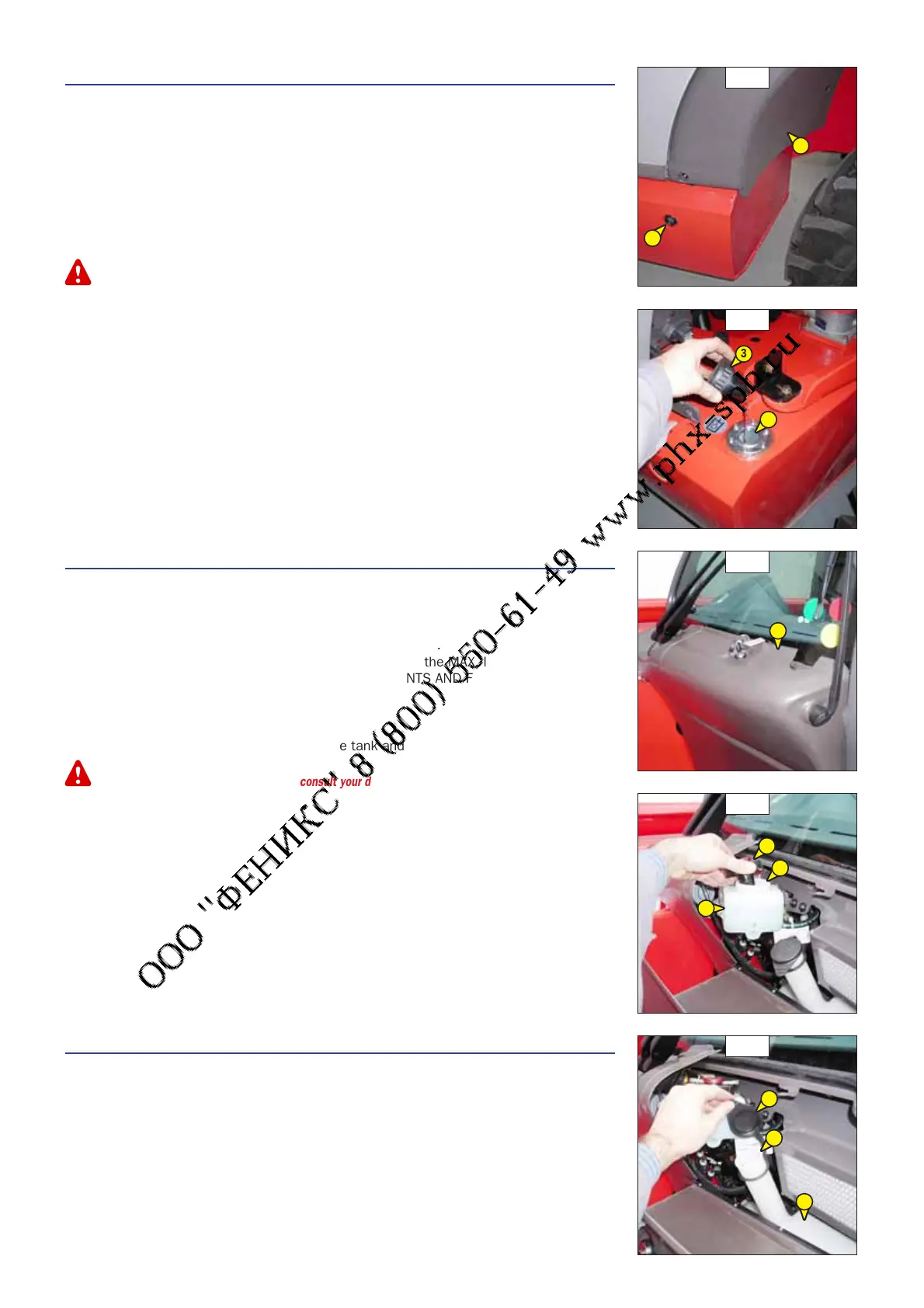

B7 - BRAKE OIL LEVEL

CHECK

Place the lift truck on level ground.

- Remove protective casing 1 (fig. B7/1) using the switch key.

- Check tank 2 (fig. B7/2). The correct level must stand at the MAX. level in the tank.

- If necessary, add oil (see: 3 - MAINTENANCE: LUBRICANTS AND FUEL).

- Remove cap 3 (fig. B7/2).

- Add oil by filler port 4 (fig. B7/2).

- Put the cap back.

- Check visually that there is no leakage in the tank and pipes.

If the braking oil level is abnormally low, consult your dealer.

B8 - WINDSCREEN WASHER LIQUID LEVEL

CHECK

- Visually check the level in tank 1 (fig. B8).

- If necessary add windscreen washer liquid (see: 3 - MAINTENANCE: LUBRICANTS AND

FUEL).

- Remove cap 2 (fig. B8).

- Add windscreen washer liquid through filler port 3 (fig. B8).

- Put the cap back.

B6/2

3

4

B7/1

1

B7/2

3

4

2

B8

1

2

3

B6/1

1

2

Loading...

Loading...