3-40

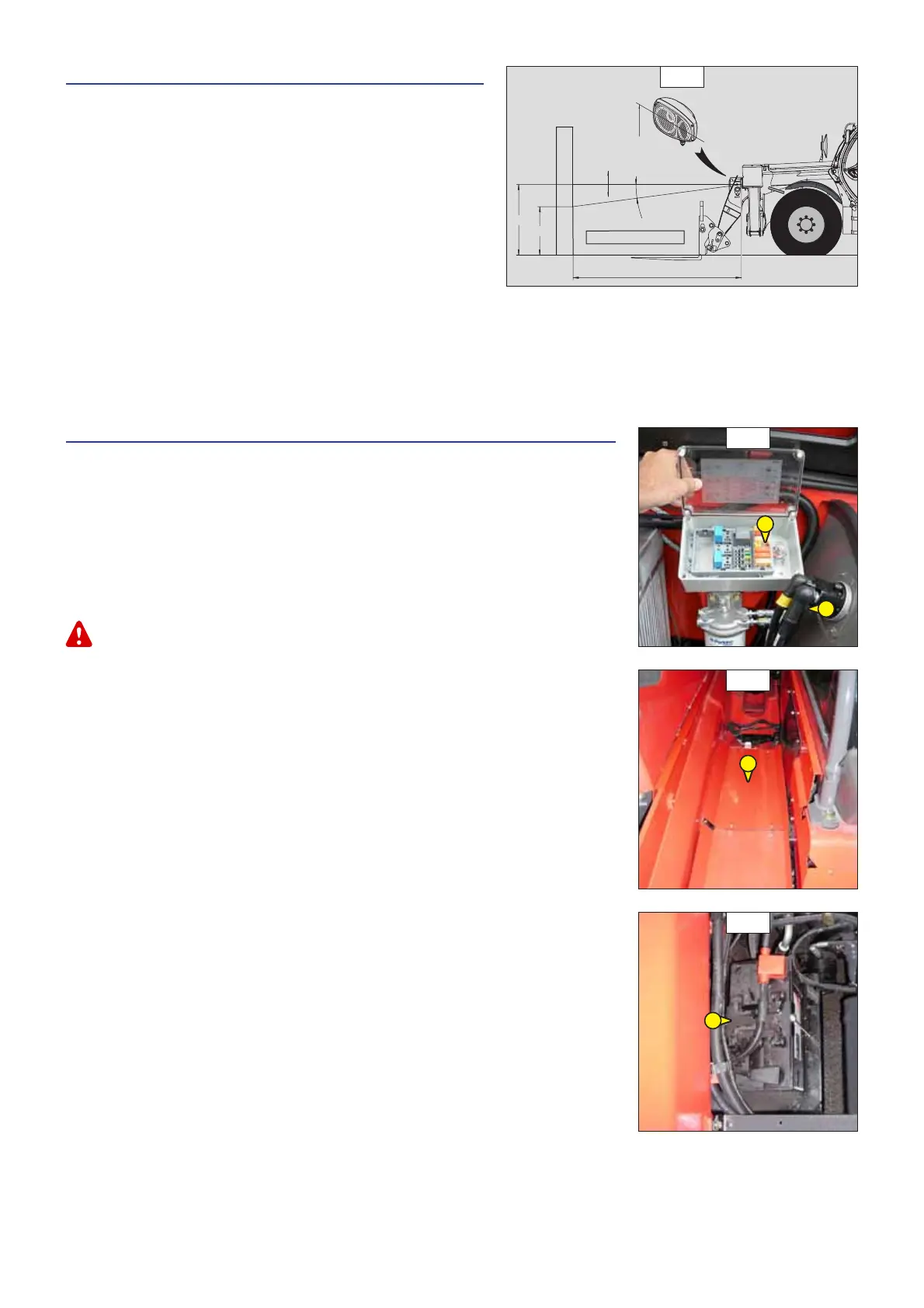

H4 - FRONT HEADLAMPS

ADJUST

RECOMMENDED SETTING

(as per standard ECE-76/756 76/761 ECE20)

Set to - 2 % of the dipped beam in relation to the horizontal line of

the headlamp.

ADJUSTING PROCEDURE

- Place the lift truck unloaded and in the transport position and

perpendicular to a white wall on flat, level ground (fig. H4).

- Check the tire pressures (see: 2 - DESCRIPTION: FRONT AND REAR

TIRES).

- Put the gearshift lever into neutral.

Calculating the height of the dipped beam (h2)

• h1 = Height of the dipped beam in relation to the ground.

• h2 = Height of the adjusted beam.

• l = Distance between the dipped beam and the white wall.

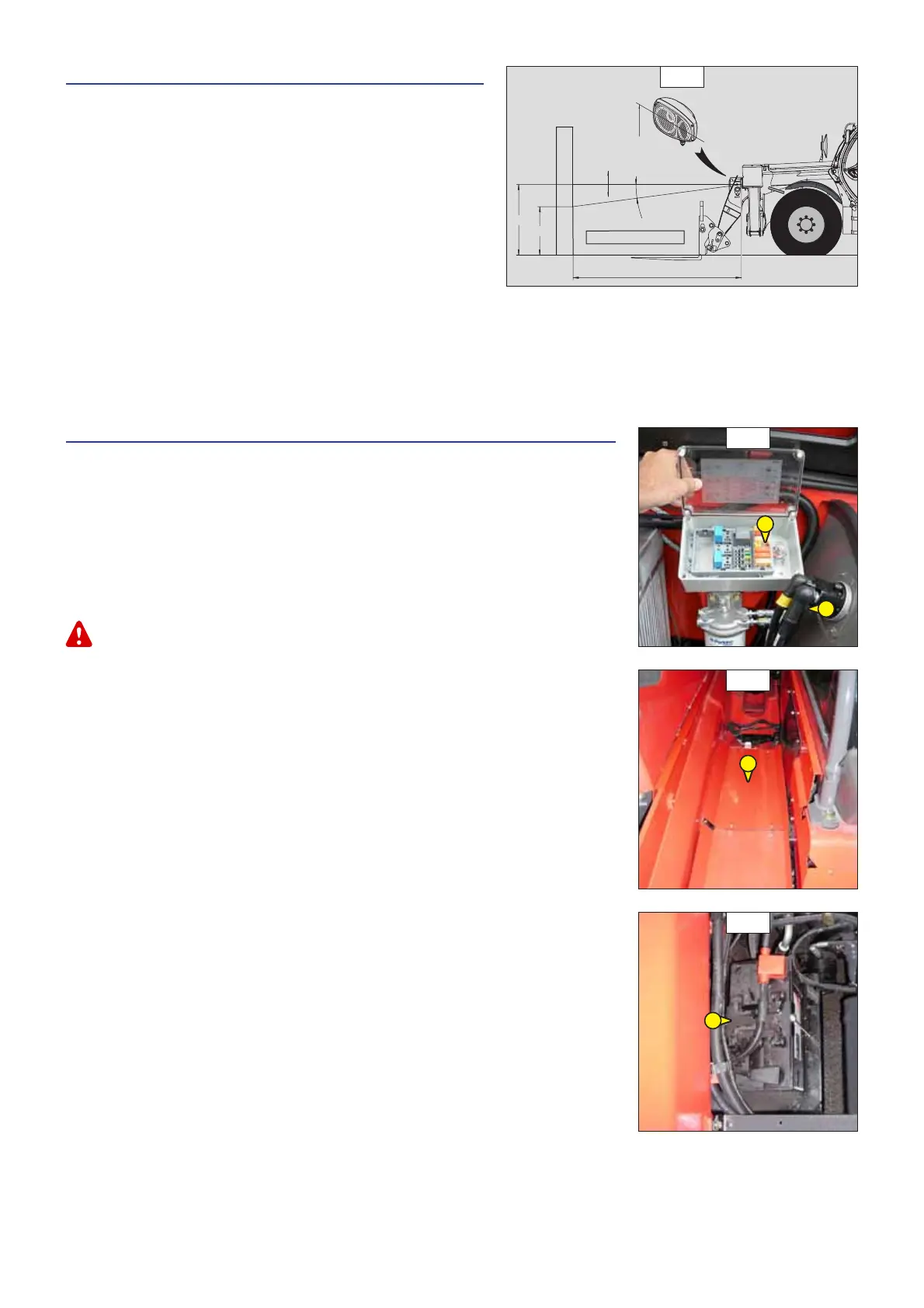

H5 - BREAKDOWN OF BATTERY

CHANGE

- Open the engine hood.

- Bring a floating battery of the same type as the one used for the lift truck and battery

cables.

- Connect the floating battery while respecting the polarity (fig. H5/1).

- Start the lift truck and remove the cables as son as the I.C engine is running.

- Raise the jib.

- Lift out protective casing 1 (fig. H5/2).

- Replace battery 2 (fig. H5/3).

Handling and servicing a battery can be dangerous, take the following precautions:

- Wear protective goggles.

- Keep the battery horizontal.

- Never smoke or work near a naked flame.

- Work in a well-ventilated area.

- In the event of electrolyte being spilled onto the skin or splashed in the eyes, rinse thoroughly

with cold water for 15 minutes and call a doctor.

+%

-%

l

h1

h2

-2%

h2 = h1 - (l x 2 / 100)

h1

H4

H5/2

1

H5/3

2

+

-

H5/1

Loading...

Loading...