Manitowoc Published 05-15-17, Control # 043-09 4-31

999 LUFFING JIB OPERATOR MANUAL SETUP AND INSTALLATION

Boom-Luffing Jib Rigging

The boom, luffing jib, and fixed jib components must be

assembled according to the instructions in this section and in

Luffing Jib Rigging Drawings.

Lifting Slings

Lifting slings are required to raise the jib with the assist

crane. Each lifting sling must have a minimum capacity of

16,000 pounds (7 257 kg).

Assist Crane

The assist crane must meet the capacity and boom length

requirements specified in Jib Luffing Assembly, Assemble-

In-Air Drawing.

Position the assist crane along either side of the boom and

luffing jib, as shown in Figure 4-15

:

1. Position assist crane boom at 70 – 80° boom angle.

2. Position assist crane on a firm, level, uniformly

supporting surface with its crawlers parallel to boom and

luffing jib.

3. Position assist crane upperworks facing in direction of

999 boom top.

4. Operate assist crane so that load line remains vertical at

all times. Assist crane must not put any side load on

boom and luffing jib.

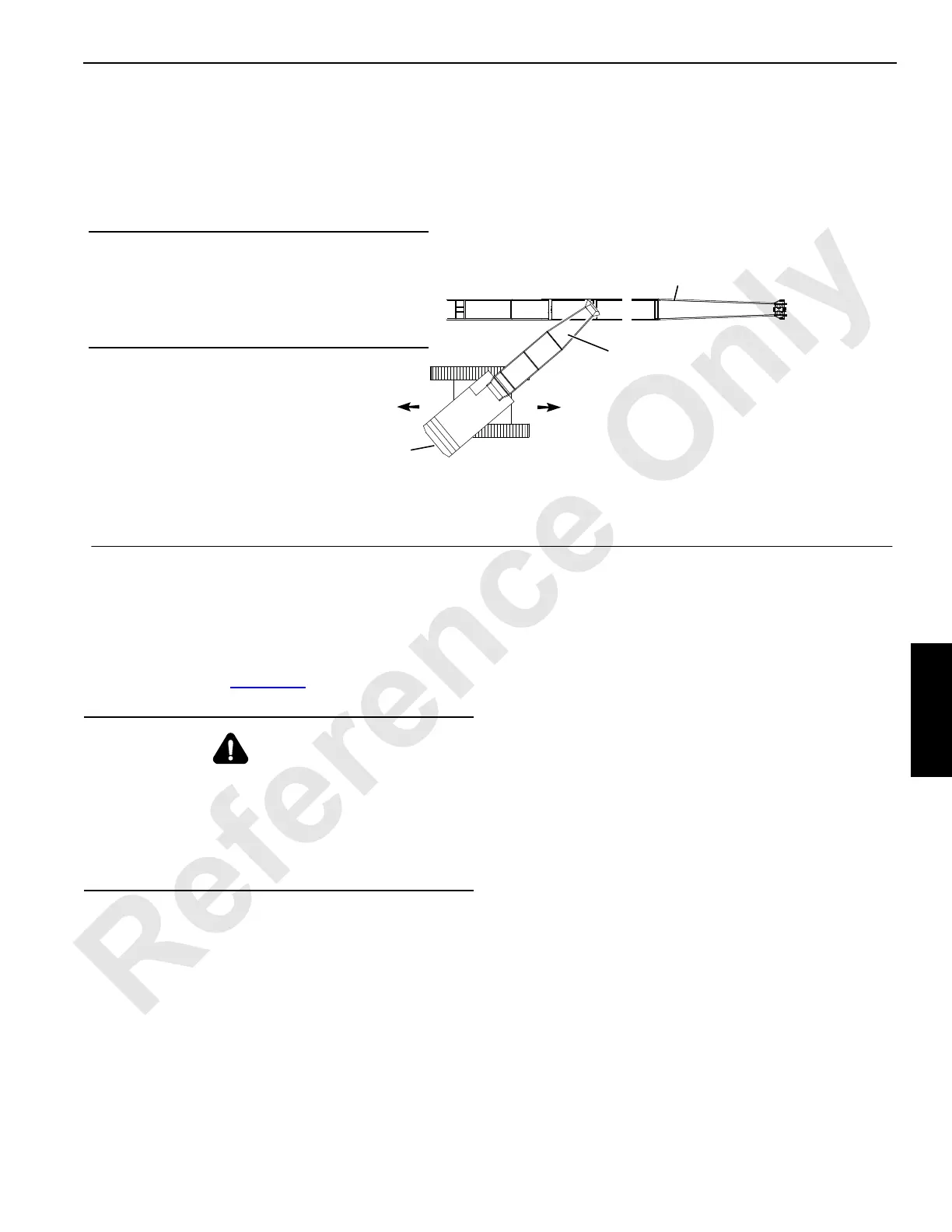

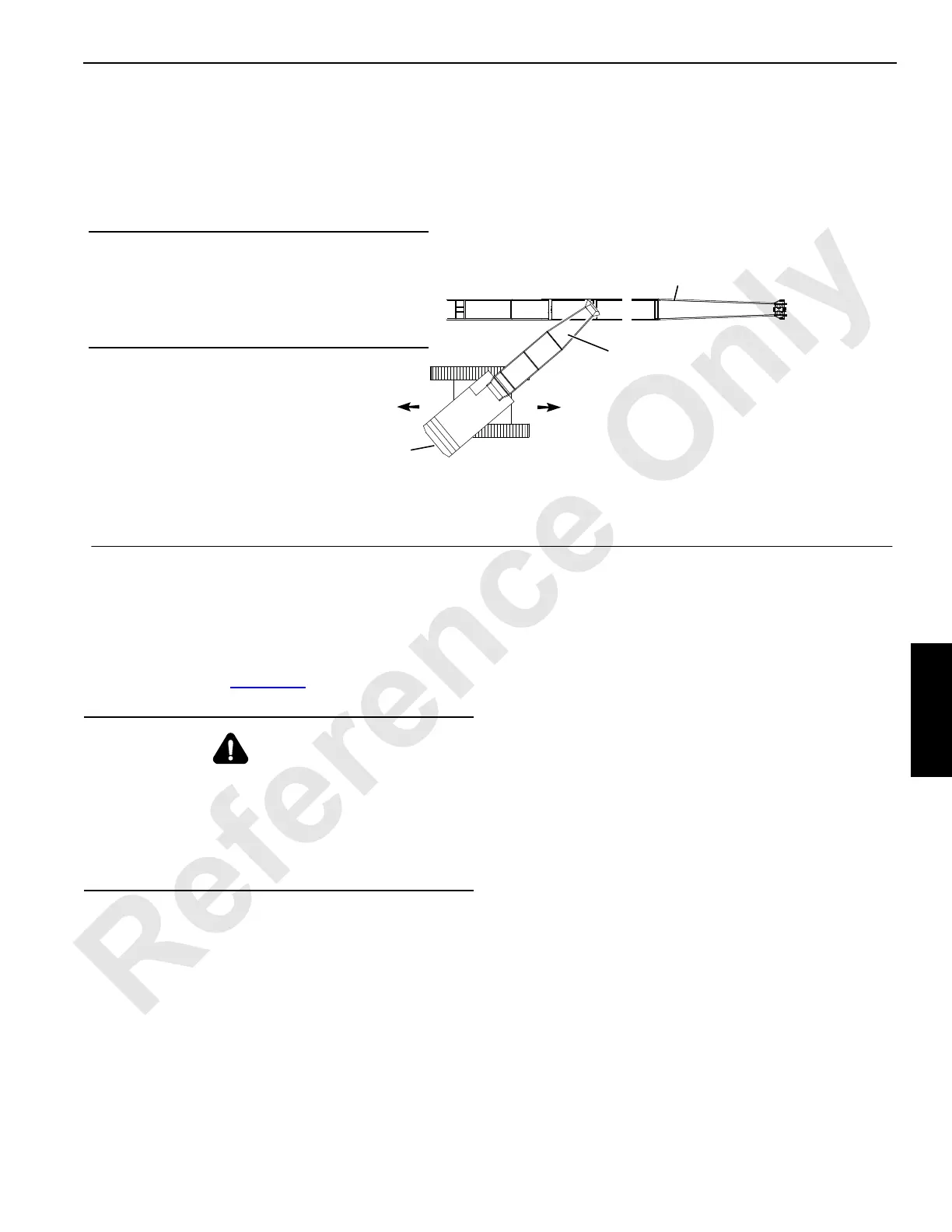

FIGURE 4-15

A590

Luffing

Jib

Travel Assist Crane Forward when

Lowering Boom and Luffing Jib

Position Assist Crane Parallel

to Boom and Luffing Jib with

Operator’s Cab Facing in

Direction of Luffing Jib Top

Travel Assist Crane in Reverse when

Raising Boom and Luffing Jib

CAUTION

Structural Damage!

Keep load line from assist crane vertical during

raising and lowering procedures. Use extreme

care not to side load boom and luffing jib.

Assist Crane Boom at

70° – 80° Angle

WARNING

Tipping Crane Hazard!

Assist crane must meet requirements specified in Jib

Luffing Assembly, Assemble-In-Air Drawing. Using too

small an assist crane or positioning and operating assist

crane improperly will result in tipping. Boom and luffing jib

could collapse.

Loading...

Loading...