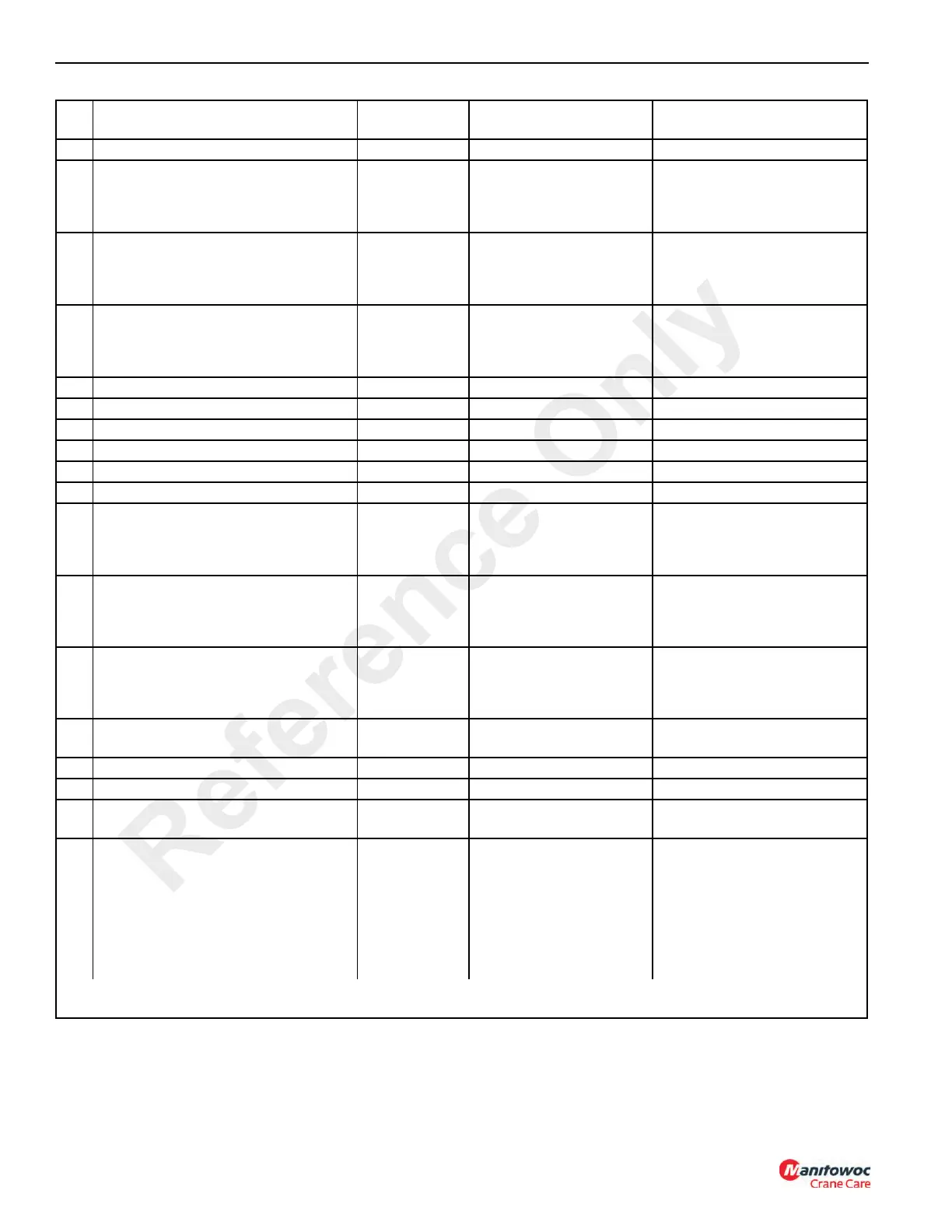

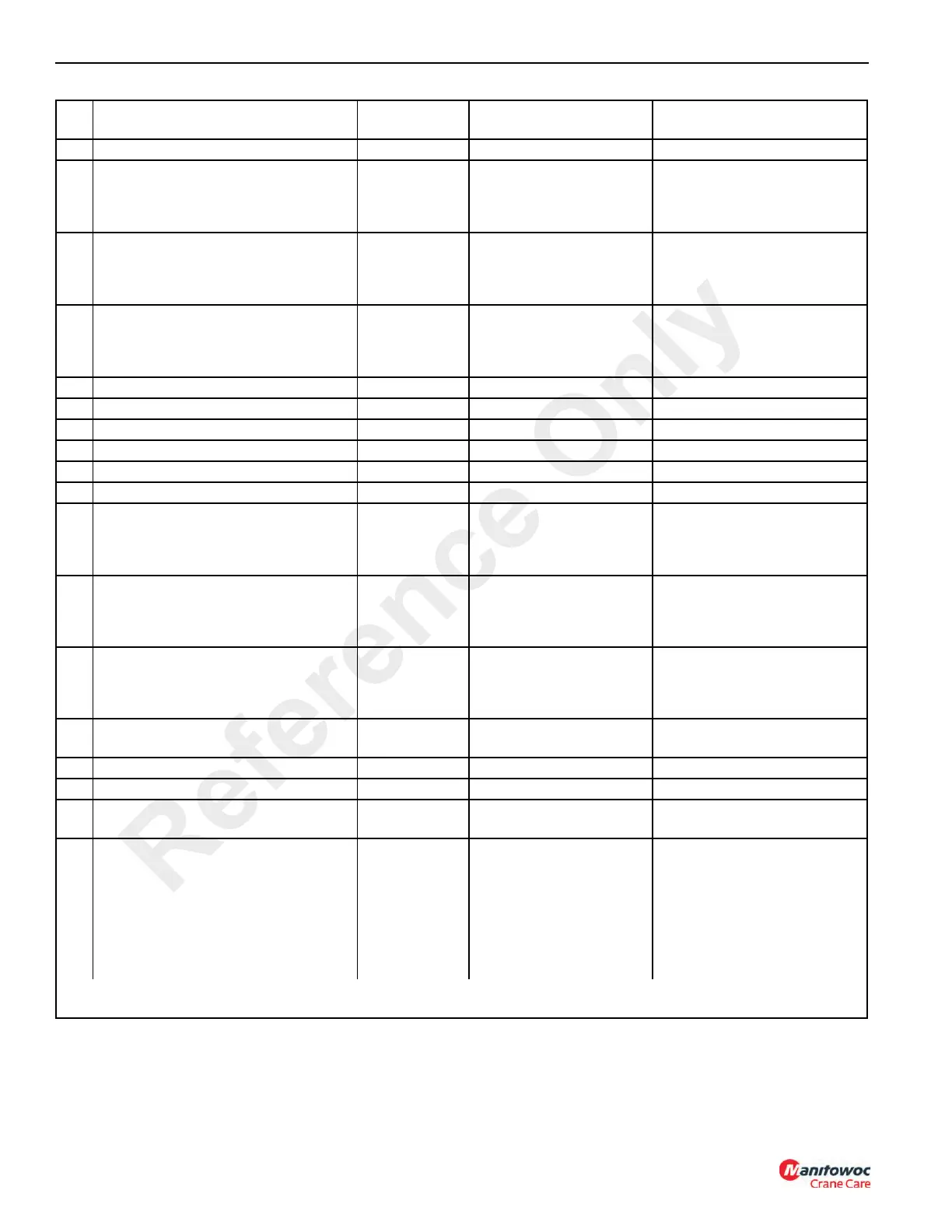

LUBRICATION NBT40 SERVICE MANUAL

8-6 Published 8-01-2017 Control # 287-11

8 Turntable bearing EP-MPG Grease gun Weekly

9

Pump Drive U-Joint - 2 ea. (If Equipped)

or

Pump Spline Shaft (Direct Mount)

Chassis Grease

Coupling Lube

Spline Lubricant

Change

Check and Fill Change

After First 100 Operating

Hours

Weekly

Semi-Annually

10a Main and Auxiliary Hoist gearbox. GL-5 Change/check & fill

After First 100 Operating

Hours

Weekly

Semi-Annually

10b Hoist brake

EO-20W-20 or

TES295

Change/check & fill

After First 100 Operating

Hours

Weekly

Semi-Annually

11 Swing drive gearbox GL-5 Change After 100 operating hours

12 Swing gear teeth EP-OGL Spray Can Monthly

13 Boom Jib EP-MPG Brush, roller, or grease gun Monthly or as required

14 Outrigger beams, bottom, sides EP-MPG Brush or roller Monthly or as Required

15 Wire rope EP-OGL Brush or spray Semi-Annually

16 Diffuser strainer, Hydraulic oil reservoir Clean Semi-Annually with Oil Change

17a

Extend Sheaves:

2nd Section 127 ft and 142 ft booms each

Side

Chassis Grease

#200S Silver

Streak Special

Multi-Lube (light)

Grease Gun Weekly

17b

Extend Sheaves:

4th Section 127 ft and 142 ft booms, each

side

Chassis Grease

#200S Silver

Streak Special

Multi-Lube (light)

Grease Gun

Weekly

18

Retract Sheaves - extend boom until

retract sheave zerks are visible through

access holes at center of boom.

Chassis Grease

#200S Silver

Streak Special

Multi-Lube (light)

Grease Gun Weekly

19

Wire Rope Jib Extension Cables (Not

Shown)

WRL Spray or Brush

Any Time Boom is

Disassembled or 5 Years

20 Boom Wear Pads EP-MPG See Boom Lubrication Monthly or as Required

21 Wire or Hose Rollers SAE 10 Oil Can Quarterly

22 Cab Heater Reservoir AFC Check/Fill/Drain

Weekly/As Required/Semi-

Annually

23 Hook Block Swivel Bearing EP-MPG Grease gun Monthly

24 Hook Block Sheaves EP-MPG Grease gun Monthly

25 Turntable Swing Lockpin EP-MPG Spray Monthly

26a Air Conditioning Pag Oil

Check & fill w/ 4 ounces

above 6 ounces in

compressor

Any Time A/C is Disconnected

or Serviced

26b Air Conditioning Refrigerant 134a 2 lbs @ start-up

NOTE: Lubricate items more frequently than interval indicated in table if environmental conditions and/or operating

conditions necessitate.

Item Application

Recommended

Lubricant

Procedure Frequency

Reference Only

Loading...

Loading...