BOOM MAINTENANCE NBT40 SERVICE MANUAL

4-2 Published 8-01-2017 Control # 287-11

Reference Figure 4-1, Figure 4-2, Figure 4-4 and Figure 4-5

for Boom Removal, Disassembly, Assembly and Cable

Tensioning.

Boom Removal

For Boom weight see Specifications in Section 9 of this

manual.

1. Extend and set machine outriggers and front stabilizer.

Boom must be completely retracted and stowed in boom

rest over front of truck.

2. If equipped, remove swing around jib according to

procedures outlined in the Set-Up Section of the

Operator’s Manual.

3. Remove hook block or downhaul weight, wind up rope

on hoist drum and stow wedge socket becket on pegs

provided on 1st section. Shut down truck engine.

4. Attach lifting device to the counterweight to provide even

weight distribution and raise the counterweight until

weight is removed from the boom pivot pin. Remove

counterweight retaining hardware from the boom pivot

pin and lower the counterweight until it rests on the rear

outrigger box.

5. Attach a lifting device to rod end of lift cylinder, remove

boom lift cylinder pin keeper and pin from bottom of 1st

section boom. Lower lift cylinder rod end to the deck.

6. Tag and disconnect extend cylinder lines and hoist

hydraulic and electric lines. Cap all openings. Unplug

anti-two-block/RCL cord from receptacle in turret.

7. Disconnect and cap all hoist hydraulic lines and

openings. Hoist may be removed at this point, but is not

necessary. (See “Hoist Removal” on page 5-2).

8. Attach a lifting device to provide even weight distribution

and raise the boom until weight is removed from the

boom pivot pin. Remove boom pivot pin keeper and

boom pivot pin. Lift boom free of turret.

Additional Maintenance, Disassembled

Boom

1. Clean all boom sections and inspect for wear, dents,

bent or crooked boom sections, gouged metal, broken

welds or any abnormal conditions. Repair or replace as

required.

2. Inspect all sheaves for excessive groove wear or

abnormal rim wear. Replace as required.

3. Inspect all sheave bearings for excessive wear or cut

inner liner material. If installed bearing diameter is

0.015 in larger than pin diameter, bearing must be

replaced. Any cut or gouge which causes the bearing

liner to lose strands is cause for bearing replacement.

4. Clean and inspect all cable assemblies according to wire

rope inspection procedures in this section. Pay

particular attention to any wire breakage at the end

connections. Replace cable assemblies as required.

Lubricate all cable assemblies before reinstalling them

in boom.

5. Inspect all sheave pins for nicks, gouges or pitting due to

rust in the bearing surface area. Replace if any damage

is evident.

6. Inspect all grease fittings and grease paths in pins to

ensure proper grease flow. Clean and replace as

required.

7. Replace all lubricating plugs (36) in all wear pads as

necessary.

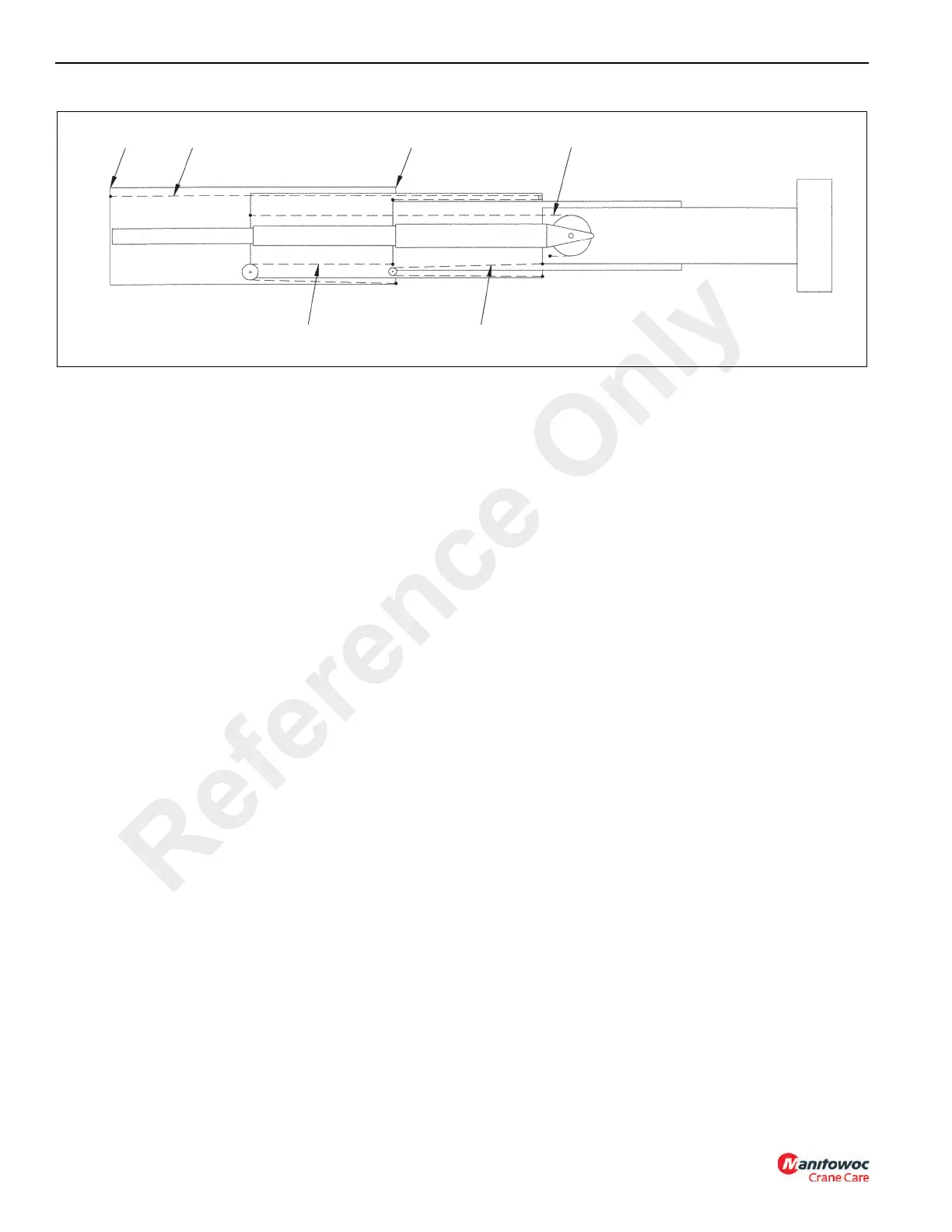

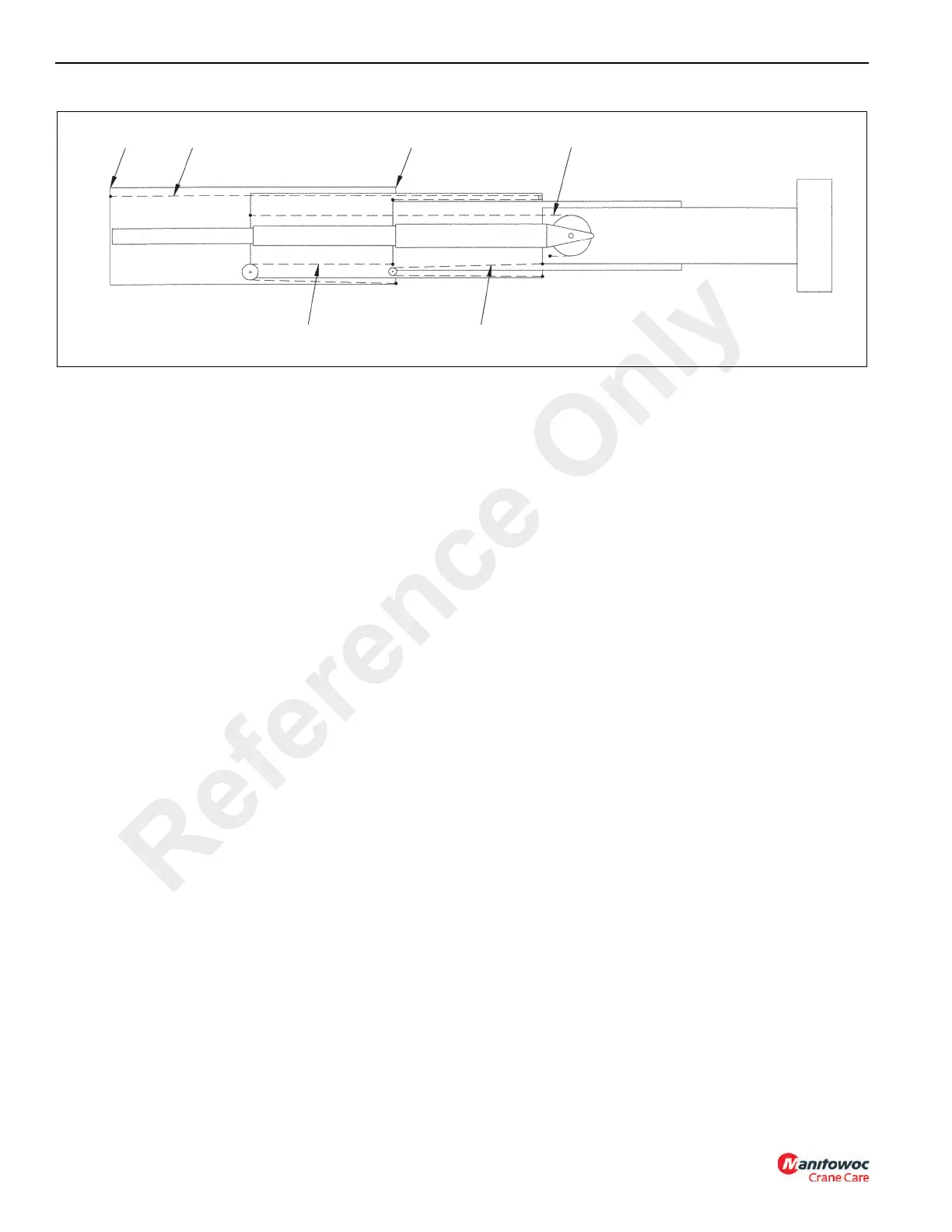

Four Section Cable Tensioning

After Boom Assembly or if Interior proportioning cables

appear loose, cable tensioning may be required.

Tensioning Setup Procedure

Tensioning must be done with the boom in the horizontal

position. reference Figure 4-4

BASE 1/2/3 EXTEND TIP 2/3/4 EXTEND

1ST STAGE 2ND STAGE 3RD STAGE 4TH STAGE

3/2/1 RETRACT

4/3/2 RETRACT

FIGURE 4-1

Reference Only

Loading...

Loading...