National Crane Published 8-01-2017 Control # 287-11 8-11

NBT40 SERVICE MANUAL LUBRICATION

• of a viscosity capable of penetrating the interstices

between wires and strands.

• not be soluble in the medium surrounding it under the

actual operating conditions (i.e. Water).

• have a high film strength.

• resistant to oxidation.

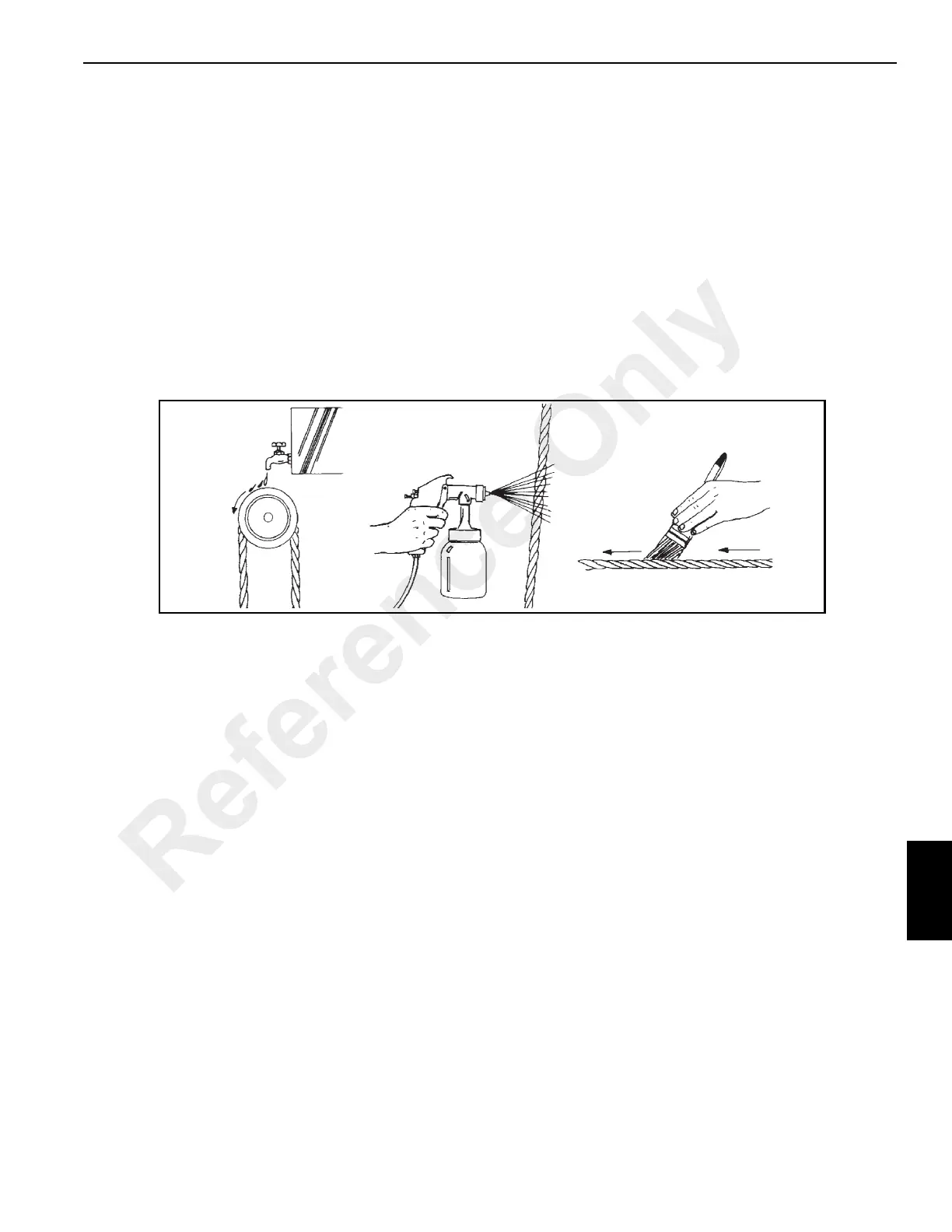

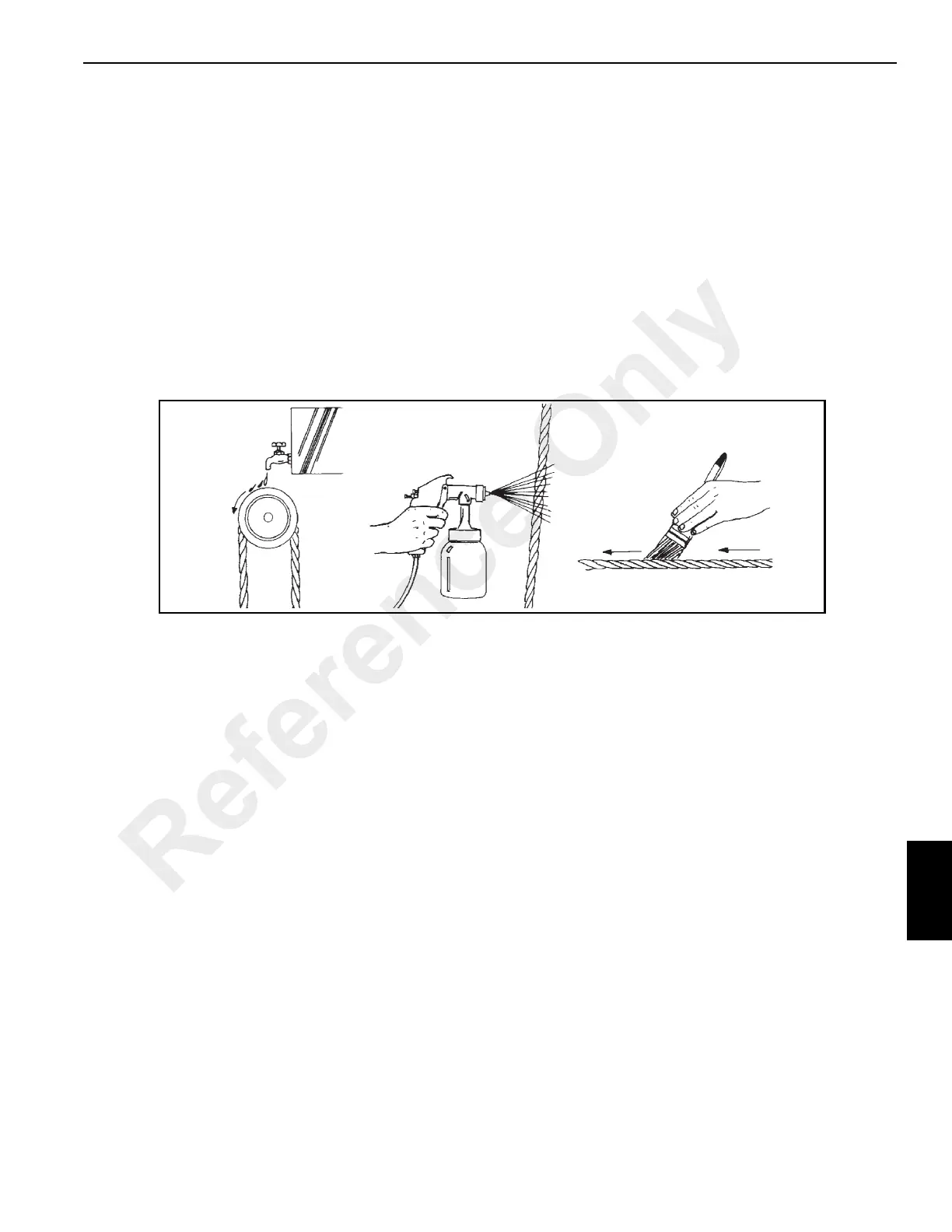

Before applying lubrication, accumulations of dirt or other

abrasive material should be removed from the rope. Clean

with a stiff wire brush and solvent, compressed air, or live

steam. Lubricate the rope immediately after the rope is

cleaned. Techniques that can be used include:

• bath

• dripping

• pouring

• swabbing

• painting

• pressure spray

Whenever possible, the lubricant should be applied at the

top of a bend in the rope, because at that point the strands

are spread by bending and are more easily penetrated.

There should be no load on the rope while it is being

lubricated. The service life of wire rope is directly

proportional to the effectiveness of the method used and

amount of lubricant that reaches the working parts of the

rope.

Reference Only

Loading...

Loading...