Section 2 Installation Instructions

Part Number 000002477 3/08 2-23

Step 4 Connecting the line set.

To prevent oxidation of the copper, purge line set and

condensing unit with dry nitrogen while brazing.

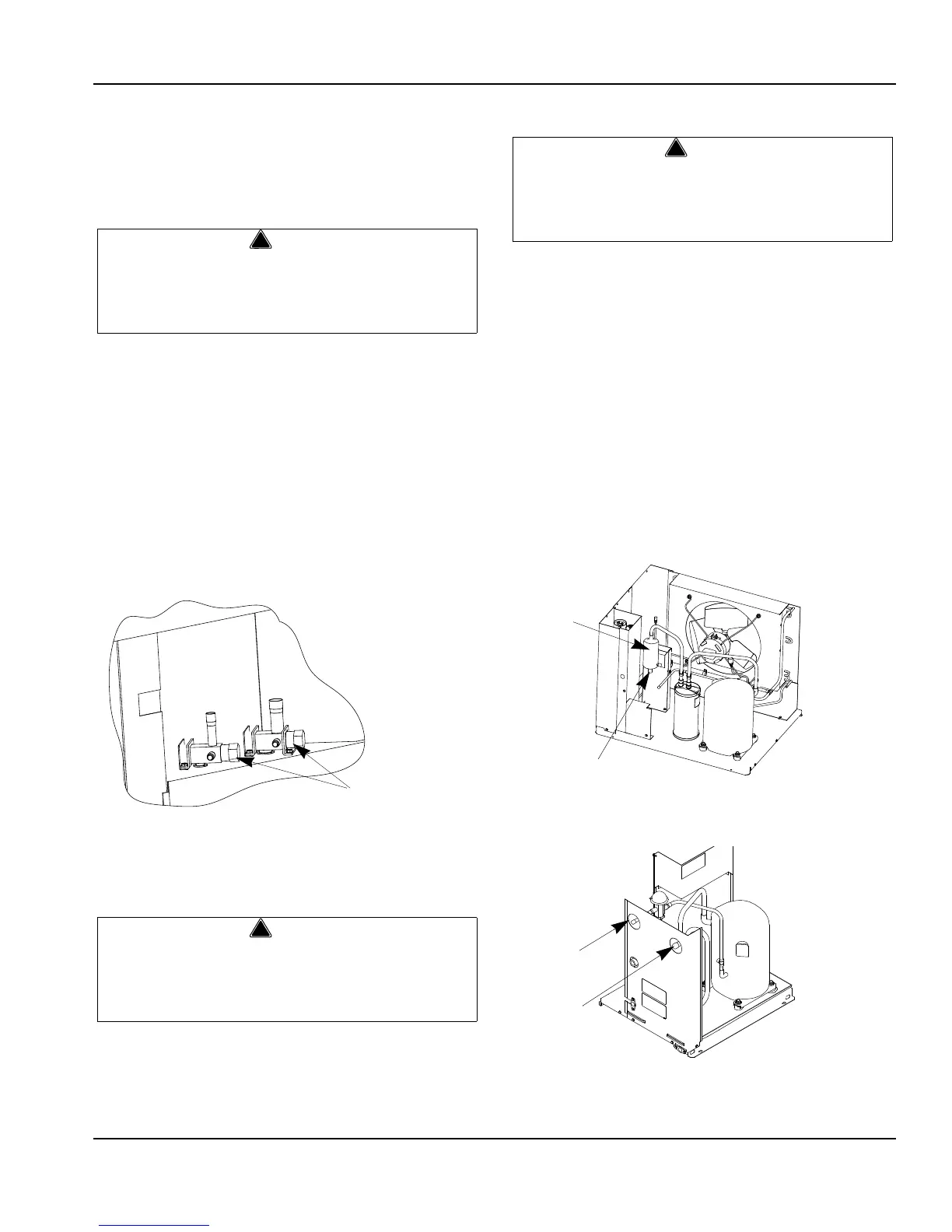

Connect The Line Set To The Ice Machine Head

Section

The line set can be routed for entry through the top or

rear of the ice machine head section.

• Top routing requires the cover to be trimmed.

• Rear routing requires the use of the supplied 90°

elbows.

The line set shut off valves at the back of the ice

machine must remain closed and be protected from heat

during the brazing process. Wrap the valves in a wet rag

or other type of heat sink prior to brazing. Cool braze

joint with water immediately after brazing to prevent heat

migration to the valve.

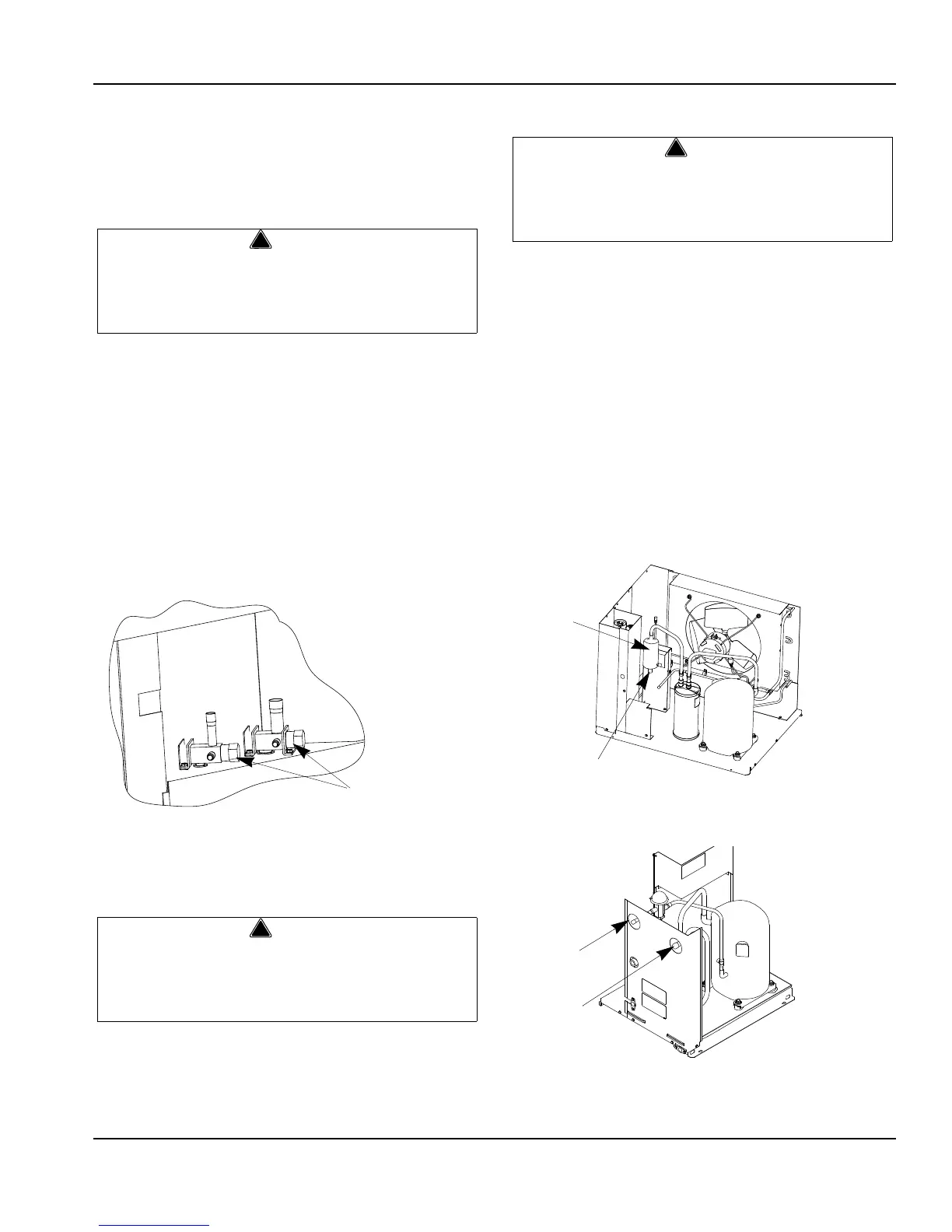

Connect The Line Set To The CVD Condensing Unit

The compressor oil rapidly absorbs moisture. Be

prepared to complete line set installation and start your

evacuation process in order to minimize the time the

compressor is exposed to the atmosphere. (Maximum

amount of time the system can be exposed to the

atmosphere is 15 minutes). The line set can be routed

for entry through the front or left side of the condensing

unit.

• Remove knockout for preferred location.

• Insert supplied plastic bushings in knockout holes to

prevent tubing from contacting sheet metal.

• Use the supplied 90° elbows to route tubing.

• Cut the tubing ends of the suction and liquid lines

and braze the line sets to the condensing unit.

The ice machine head section contains refrigerant

charge. The ice machine head section contains three

(3) refrigeration valves that must remain closed until

proper installation of the line sets is completed.

The condensing unit ships from the factory

pressurized with a 50/50 mixture of nitrogen/helium.

Bleed off pressure from both suction and liquid line

access ports prior to cutting into refrigeration lines.

VALVES MUST REMAIN

CLOSED AND BE

PROTECTED FROM

HEAT WHEN BRAZING

(WRAP WITH WET RAG)

SV1757

The condensing unit ships from the factory

pressurized with a 50/50 mixture of nitrogen/helium.

Bleed off pressure from both suction and liquid line

access ports prior to cutting into refrigeration lines.

SV2085

MINIMIZE THE TIME THE REFRIGERATION

SYSTEM IS EXPOSED TO THE ATMOSPHERE

(15 MINUTES MAXIMUM)

SUCTION

FILTER

SUCTION

LINE

LIQUID

LINE

SUCTION

LINE

SV3077

Loading...

Loading...