3

INSTALLATION

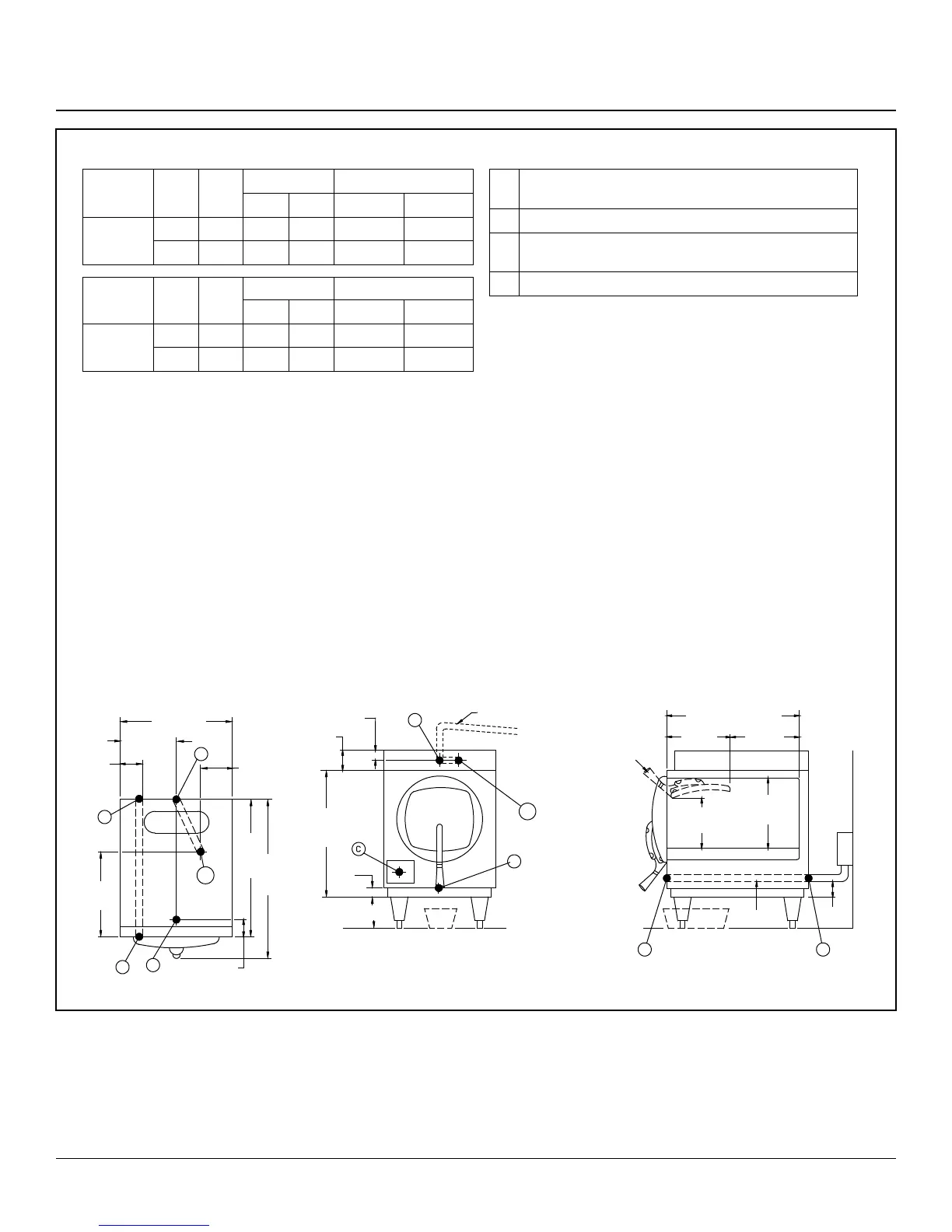

Service Connections

Figure 1

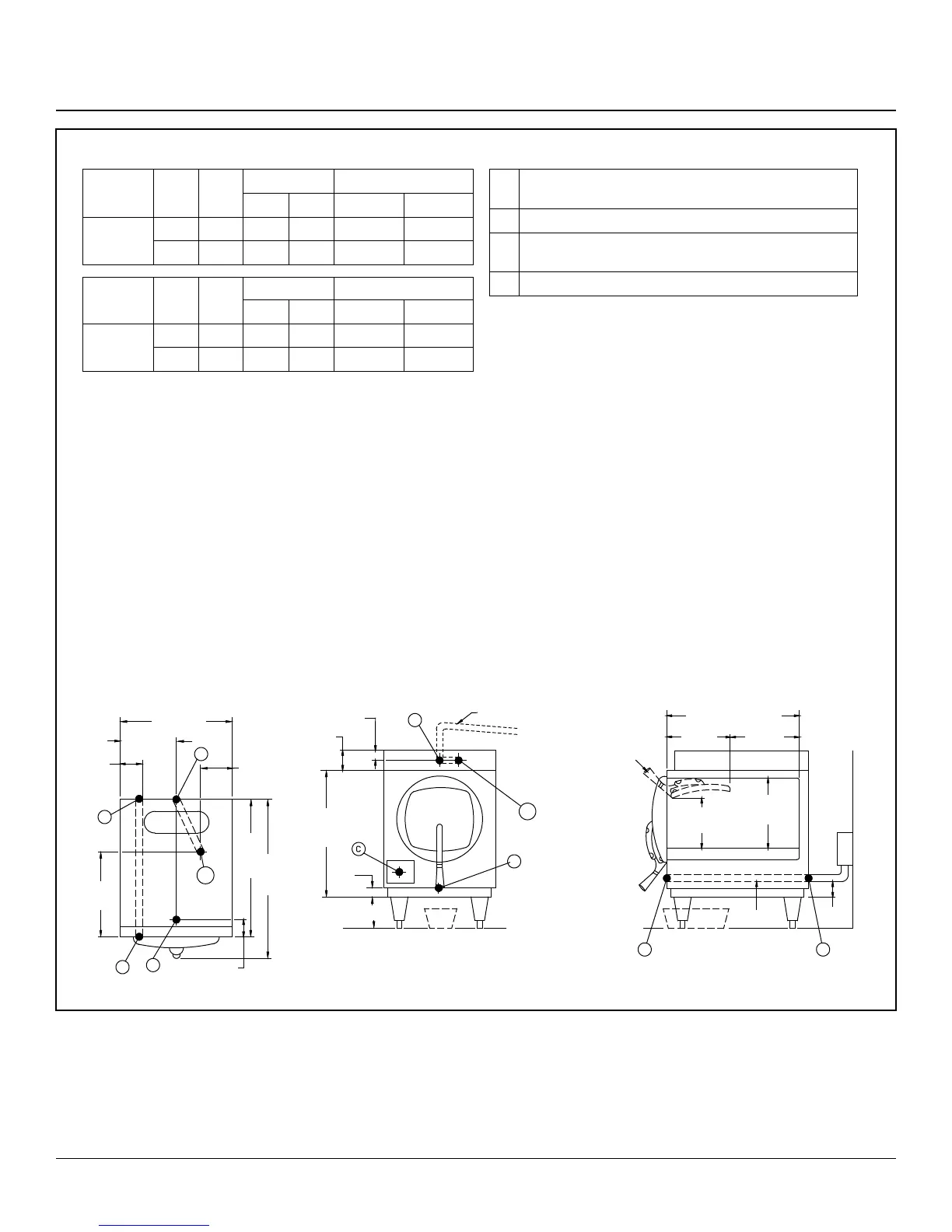

ELECTRICAL SPECIFICATIONS

Domestic

Models

kW Hz

1 Phase

3 Phase

208V 240V 208V 240V

STM-E

STM-EL

9.3 60 45A - 26A -

12.4 60 - 52A - 30A

Export

Models

kW Hz

1 Phase

3 Phase

220V 240V 220/380V 240/415V

STM-EX

STM-ELX

10.4 50 48A - 16A -

12.4 50 - 52A - 18A

Unit must be grounded. Main supply voltage fluctuations are not to

exceel ± 10% nominal supply voltage.

WATER SUPPLY

Good quality water feed is the responsibility of the owner. Water qual-

ity must be within the following general guidelines.

TDS: 40-125 ppm Hardness: 35-100 ppm Chlorine: <0.2 ppm

Silica: <13 ppm Chlorides: <25 ppm

Chloramine: <0.2 ppm pH: 7.0 - 8.5

The best defense against poor water quality is a water treatment

system designed to meet your water quality conditions.

Appliance to be installed with backflow protection according to fed-

eral, state or local codes.

DIMENSIONS ARE IN INCHES [MM]

SEE NOTE 2

B

2 [57]

4.63 [117]

23 [584]

1 [25]

6 [152]

B1

A

4 [102]

ADJ. LEGS

Customer provided Drain Catch Pan

Approx. 4-6 quarts (3.8-5.7 liters)

21 [533] CHAMBER

9 [230]

12 [305]

DOOR IN

OPEN POSITION

9 [228]

CLEARANCE

11 [280]

CLEARANCE

C

D

CONDUIT

3 [76]

Locate electric box as close to

sterilizer as possible and per

local electrical codes

D

CONDUIT

15.5

[394]

3.5

[89]

C

A

9.34 [237]

18.69 [475]

B

SEE

NOTE 2

4.75

[121]

B1

25 [635]

1.5 [38]

30 [762]

SERVICE CONNECTIONS

A Drain - 1/2” (13mm) N.P.T. of 3/8” (10mm) OD copper

(see note 1)

B Steam Exhaust Connection - 5/8” (16mm) (see note 2)

C Electrical Connection - (*see electrical specifications

table)

D Power Supply

NOTES:

1. An air break must be provided if a unit drain line is run.

2. Vent exhaust to atmosphere. B1 is actual connection, but

must exit casing at B.

3. Heat of Rejection (Heat Loss Into the Room) 6,000

BTU’S.

IMPORTANT: Exhaust line must be vented to the outside to elimi-

nate the exhaust steam and the accompanying noise from enter-

ing the room. Use 1/2” (13mm) copper tubing or suitable alternate.

The overall height and length of the line should not rise more then

4’ (1.2 meters) above the unit and exceed 15’ (4.5 meters) with a

minimum of bends. The line should slope downward after leaving

the sterilizer in order to ensure condensate drainage.

IMPORTANT: Failure to comply with this outline will affect the

sterilization process.

When an exhaust condenser is supplied; the following services

must be provided: 1/2” (13mm) cold water: 1” (25mm) waste:

115V electrical line.

Loading...

Loading...