The end clearance is adjusted by means of color coded Shim Gaskets between the end cover and

the cylinder. Make note of the color and quantity of any Shim Gaskets when removing the end

cover. The matching quantity and color will need to be used on reassembly.

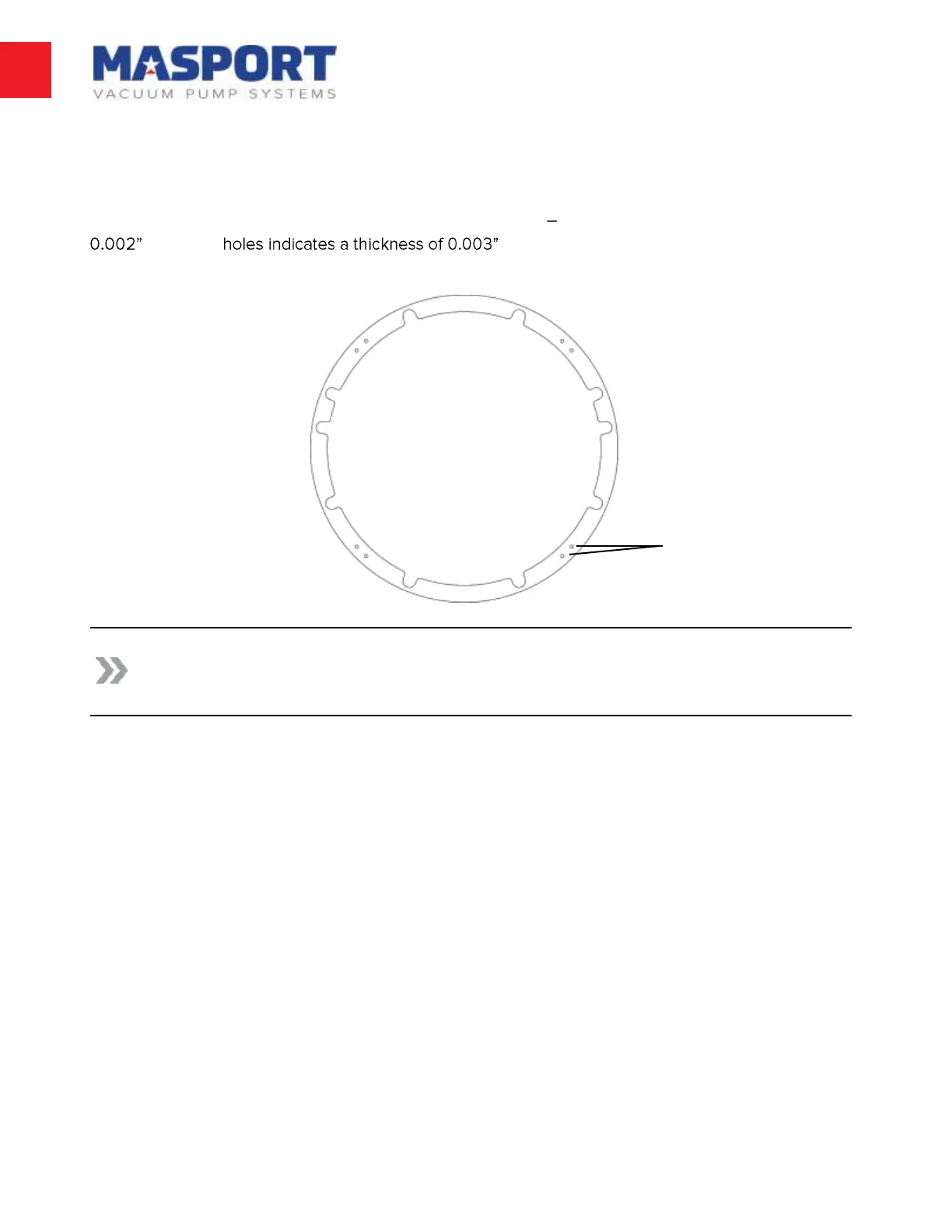

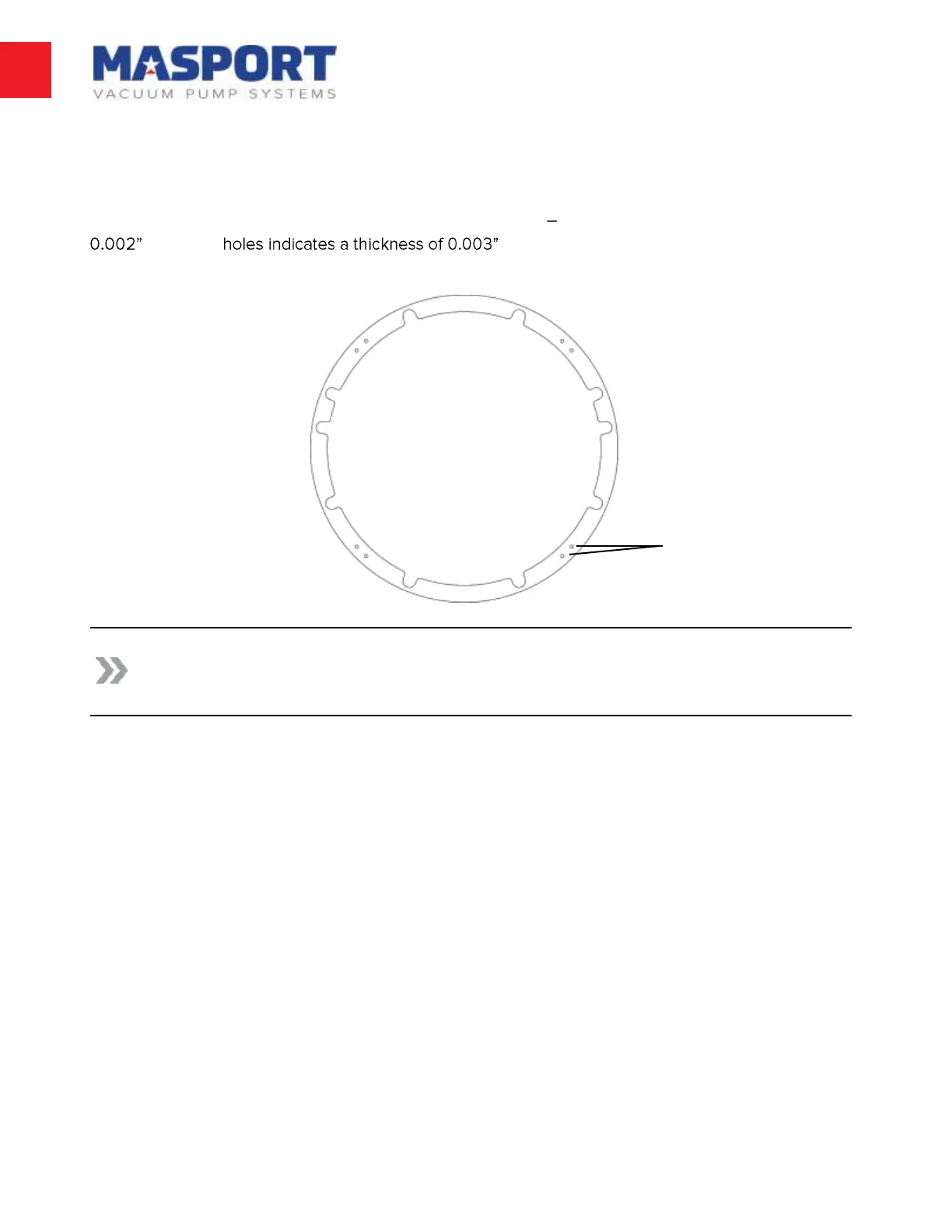

The marker holes on the Shim Gaskets identify the thickness i.e. two holes indicates a thickness of

and three

Note: If simply replacing the vanes only please skip to the Vane Wear Check section in

Parts Inspection, Cleaning and Replacement.

Rotor Removal:

With the one end cover removed, the rotor can be pulled out of the cylinder. The bearings are a slip

fit in the end covers, but due to the tight clearance, the bearing may bind in the end cover if it is not

pulled out straight. If it does not pull free on the first try, put it all the way back in, using a rubber

mallet, and start over again. Putting it all the way back in will realign the bearing with the housing

and allow it to pull free from the cover.

Once the rotor has been removed, the remaining end cover can be removed, as required, by

following the same procedure detailed above in the End Cover Removal section.

Parts Inspection, Cleaning and Replacement:

Vane Wear Check:

The pump should be inspected for vane wear at least once a year. If vane wear is not monitored, the

vanes can become too short causing excessive rotor and cylinder wear and eventually result in vane

breakage.

Loading...

Loading...