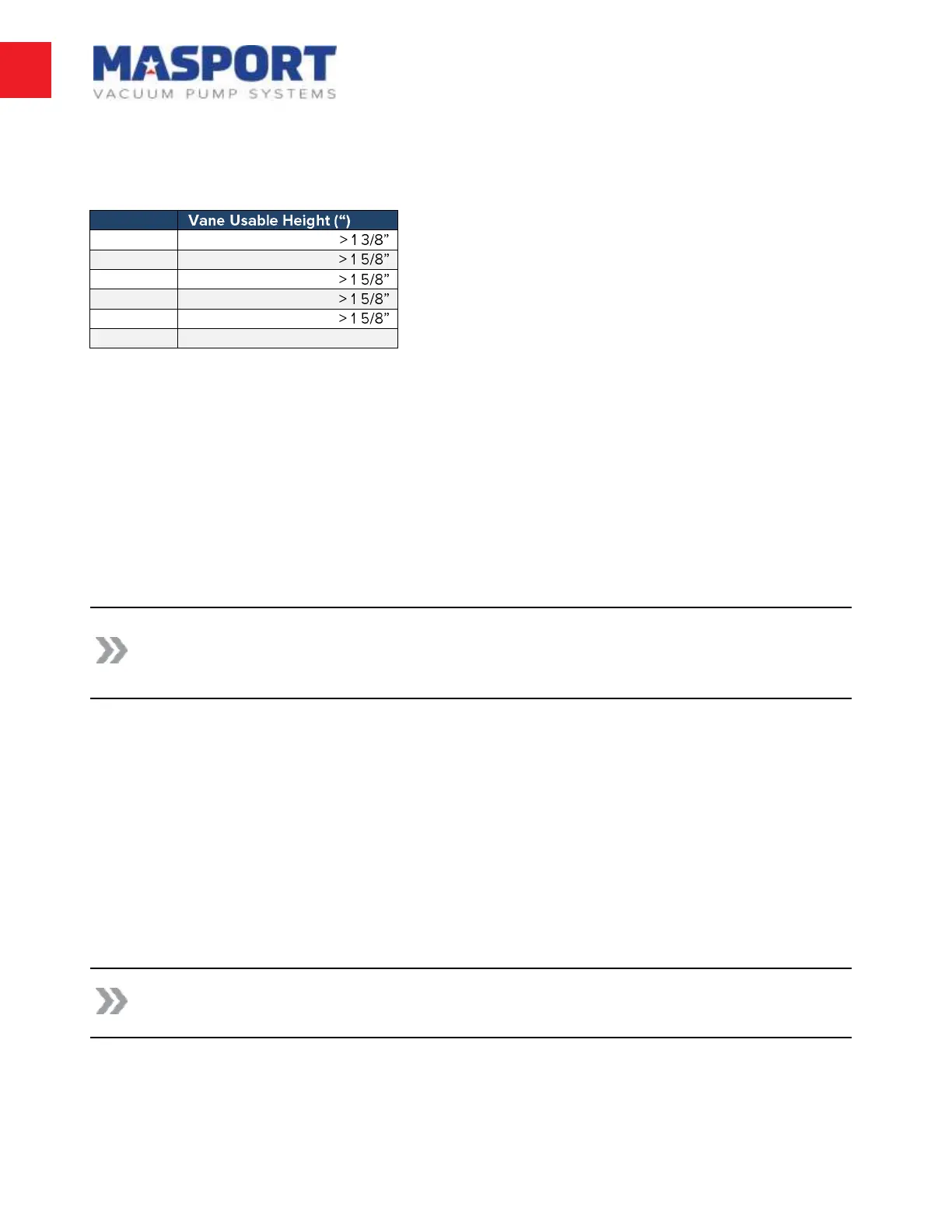

Measure the vanes to see if they are within the usable limit. If they are not they should be discarded

and replaced. The vanes should be replaced when there height is below the usable limit detailed in

the table below:

Inspect the sides of the vanes to see if they are bent, out of parallel, worn to a concave shape on

one side or have frayed edges. Any of these conditions require part replacement. These

characteristics could indicate foreign material caught alongside the vane, a burr in the edge of the

rotor slot or improper lubrication. Each of these possible causes should be investigated and

corrected before the pump is reassembled.

Inspect the edge of the vane that contacts the cylinder for frayed edges. If detected this requires

part replacement. Frayed edges can indicate improper lubrication or that the pump has been

operated for extended periods of time beyond its rated limits. Each of these possible causes should

be investigated and corrected before the pump is reassembled.

Note: If simply replacing the vanes only please skip to the Installing the Vanes section in

Reassembly.

Cylinder Inspection:

With the end cover removed inspect the cylinder for damage or corrugation. Prior to inspection, the

cylinder should be cleaned inside and out to allow a more thorough inspection.

Inspect the interior of the cylinder for cracks and deep gouges around the circumference and

corrugation across the length of the bore. Cracks in the housing will require part replacement.

The detection of corrugation or gouges across the length of the cylinder can indicate inadequate

horsepower transfer, operation below minimum recommended speeds, foreign material sticking the

vanes in their slots, or operation beyond recommended vacuum limits. Each of these possible

causes should be investigated and corrected before the pump is reassembled.

Note: If cylinder scoring is deeper than .005" or if corrugation can be felt the cylinder

should be bored, honed and the seal gap reset.

Loading...

Loading...