18

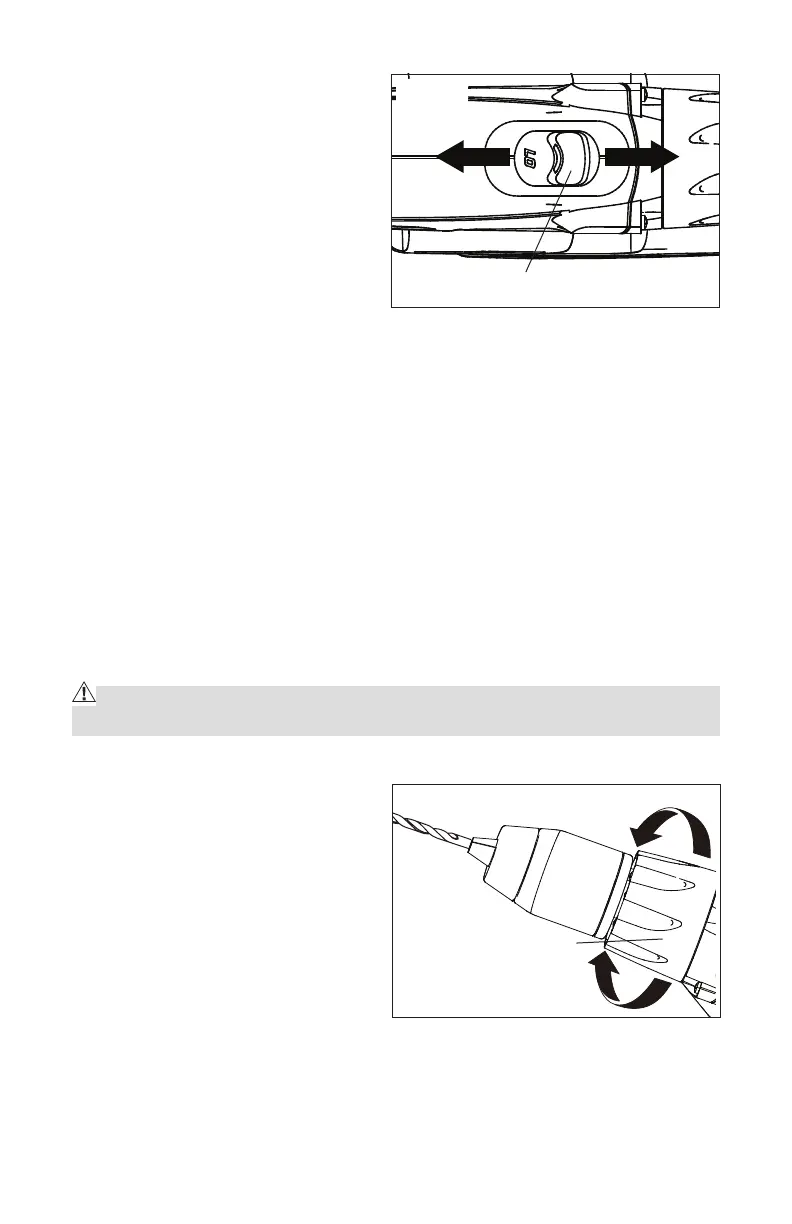

TWO-SPEED GEAR BOX (Fig. 8)

The drill/driver has a two-speed

gear box designed for drilling or

driving at LO or HI speeds. A slide

switch is located on the top of the

drill/driver to select either LO or HI

speed.

When using drill/driver in the

LO speed range, the speed will

decrease and the drill/driver will

have more power and torque. When using drill/driver in the HI speed range,

the speed will increase and the drill/driver will have less power and torque.

Use LO speed for high power and torque applications and HI speed for fast

drilling or driving applications.

Use LO speed for starting holes without a center punch, drilling metals or plastic,

drilling ceramics, or in applications requiring a higher torque (see below).

HI speed is better for drilling wood and wood composites and for using

abrasive and polishing accessories.

NOTE: Avoid running the drill/driver at LO speed for extended periods of

time. Running at LO speed under constant use may cause the drill/driver to

become overheated. If this occurs, cool the drill/driver by running it without a

load at HI speed.

CAUTION: Never change gears while the tool is running. Failure to obey this

caution could result in serious damage to the drill/driver.

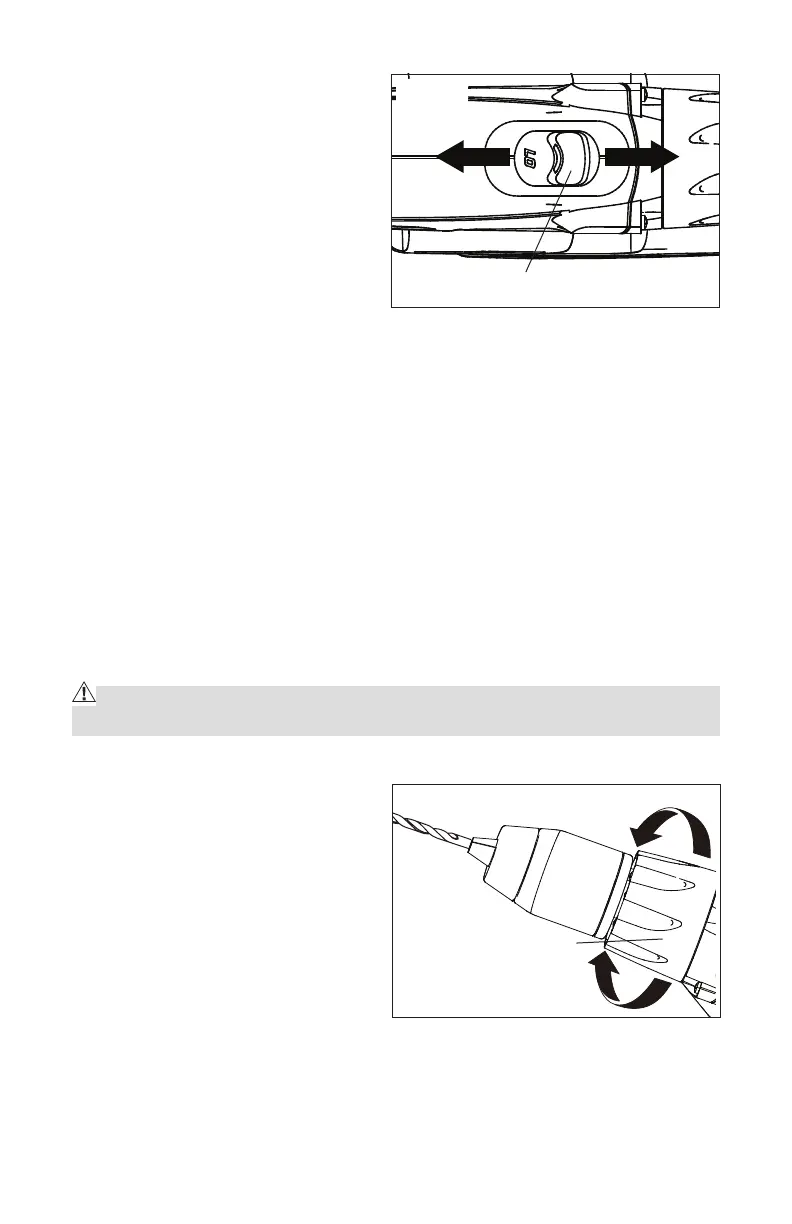

ADJUSTABLE TORQUE CLUTCH (Fig. 9)

The torque clutch can be adjusted

to 23+1 different settings. The

higher the torque setting, the more

force the drill/driver produces to

turn an object in either LO or HI

rotation speed.

When using the drill/driver for

different driving applications, it is

necessary to increase or decrease

the torque in order to help prevent

the possibility of damaging screw heads, threads, workpiece, etc.

Adjust the torque by rotating the torque-adjustment ring.

The proper setting depends on the job and the type of bit, fastener, and

Fig. 9

Fig. 8

Two-speed gearbox switch

To increase torque

Torque adjustment ring

To decrease torque

Loading...

Loading...