WARNING: When servicing, use only identical replacement parts. Use of any other part may create a hazard or

cause product damage.

WARNING: Always wear safety goggles or safety glasses with side shields during power tool operation or when

blowing dust. If operation is dusty, also wear a dust mask.

WARNING: Do not at any time let brake uids, gasoline, petroleum-based products, penetrating oils, etc.,

to come in contact with plastic parts. They contain chemicals that can damage, weaken, or destroy plastic.

WARNING: To ensure safety and reliability, all repairs should be performed by a qualied service technician at an

authorized service center to avoid risk of personal injury.

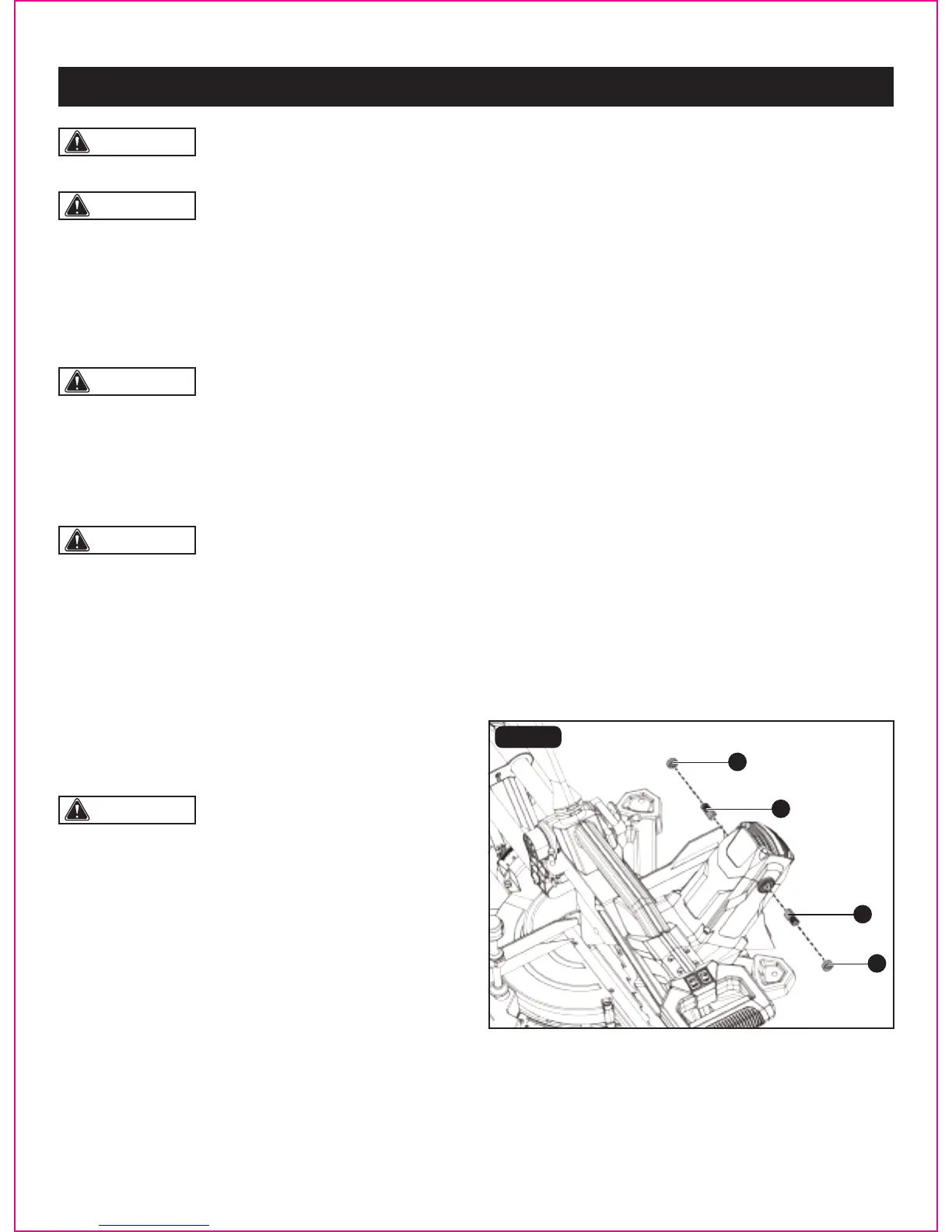

FIG. 34

MAINTENANCE

Page 39

GENERAL MAINTENANCE

LUBRICATION

Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, carton dust, etc.

All of the bearings in this tool are lubricated with a sufcient amount of high grade lubricant for the life of the unit under

normal operating conditions. Therefore, no further lubrications are required.

WARNING: Failure to unplug the saw could result

in accidental starting causing serious injury.

BRUSH REPLACEMENT (FIG. 34)

The saw has externally accessible brush assemblies that

should be periodically checked for wear.

• Unplug the saw.

• Remove the brush cap (A) with a screwdriver. The brush

assembly is spring loaded and will pop out when you

remove the brush cap.

• Remove the brush assembly (B).

• Check for wear. Replace both brushes when either has

less than 1/4 in. length of carbon remaining. Do not replace

one side without replacing the other.

• Reassemble using new brush assemblies. Make sure that

the curvature of the brush matches curvature of the motor

and that the brush moves freely in the brush tube.

• Make sure that the brush cap is oriented correctly (straight)

and replace.

• Tighten the brush cap securely. Do not over-tighten.

Some areas will require infrequent lubrication. You will need to apply:

• Automotive oil directly the slide bars.

• Light oil or pressurized light spray oil to the arm pivot shaft.

• Light oil or pressurized light spray oil to the torsion spring.

B

B

A

A

Loading...

Loading...