2 www.mastercool.com

SAFETY INFORMATION

READ CAREFULLY BEFORE USING THE 69500 RECOVERY SYSTEM!

1. This equipment is designed to be used by qualified service personnel. The operator of this equipment must be familiar

with air conditioning and refrigeration systems. Do not attempt to operate this equipment until all safety instructions

and operating instructions are read and understood.

2. Always use eye protection (safety goggles) and hand protection (gloves) when working with refrigerants. Other types of

personal protective equipment should also be used.

3. Do not pressure test system with air. Some mixtures of air and refrigerant can be combustible or explosive.

4. READ CAREFULLY BEFORE USE OF RECOVERY/RECYCLE SYSTEM.

A) When not in use or in storage, recovery/recycle system should have a slight positive pressure in system using an

environmentally acceptable refrigerant (134a, etc.). This prevents moisture and air from contaminating the filter and

moisture indicating sight glass.

B) After every use of recycle system, oil separator must be drained. This prevents cross contamination of oil/refriger-

ants and carry over that may occur if oil separator is not empty. “Valves 9, 10, and 11” should be closed when recycle

system is not being used. See operating instructions for draining procedure of oil separator.

C) Recycle system must always be mounted vertically so that oil separator is in an up-right position with “valve

9” pointing down and “valves 10 and 11” pointing up. This is very important for the proper operation of the oil

separator and to prevent oil contamination of recycle system.

5. Recovery tank contains liquid refrigerant under high pressure. Never over fill recovery tank. Tanks should be filled to a

maximum of 80% of capacity only. Use scale only to continuously monitor the recovery tank weight. Use only approved

tanks for refrigerant recovery. An overfilled tank can explode causing serious injury or death.

6. Do not breath refrigerant vapors and/or lubricant vapor or mist. Breathing high concentrations of these substances will

cause severe health problems. Always use Recovery System in a well ventilated area.

7. This equipment is intended for use with one type refrigerant at a time until the self-purging feature is used. Mixing of

different refrigerants will cause your recovered supply of refrigerant to become contaminated.

NOTE: It is very expensive to destroy mixed or damaged refrigerants!

DANGER! – EXPLOSION RISK!!! DO NOT RECOVER FLAMMABLE REFRIGERANTS

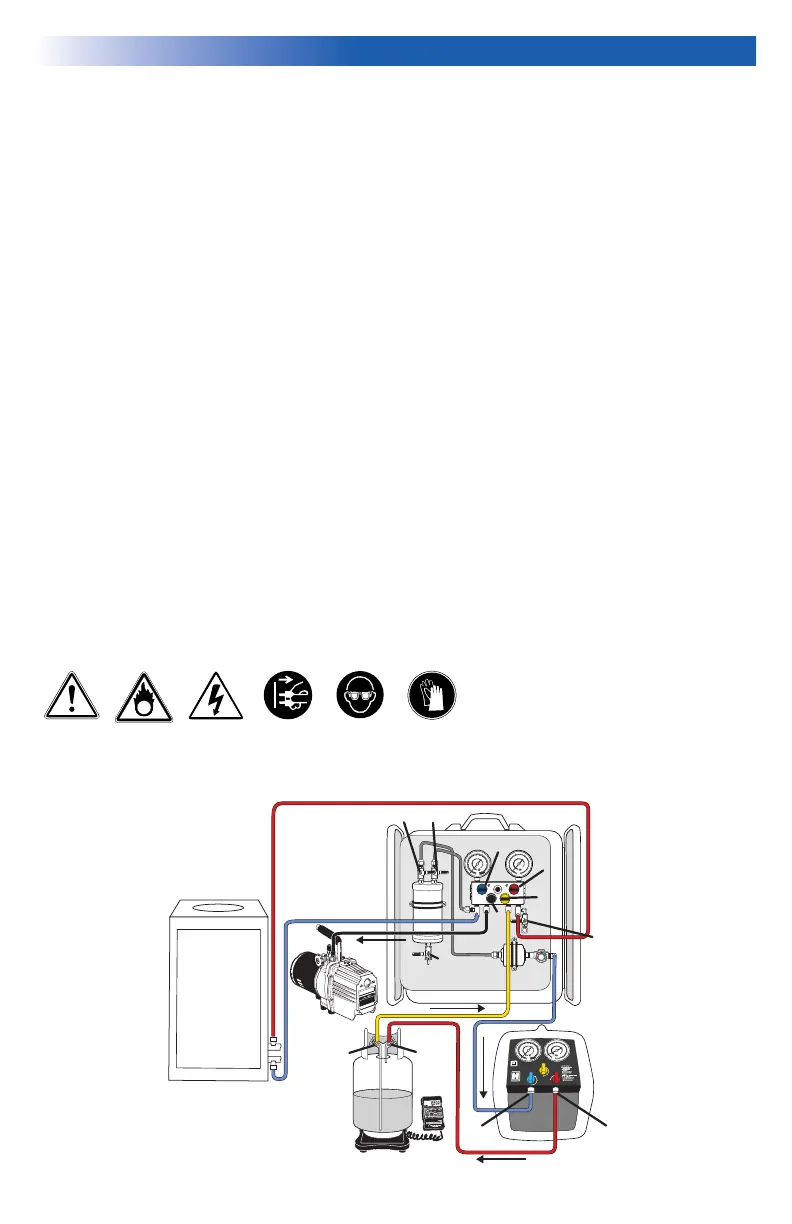

USE OF RECOVER / RECYCLE SYSTEM

LIQUID

SUCTION PRESSURE DISCHARGE PRESSURE

PURGE

PURGE (START)INLET

POWER

CIRCUT

BREAKER

OUTLET

CLOSE

30

25

2

0

15

1

0

5

0

2

0

0

2

5

0

3

0

0

350

4

0

0

4

5

0

150

100

5

0

0

P

S

I

BAR

R

1

3

4

a

M

C

4

0

6

0

5

0

70

8

0

30

2

0

10

0

1

9

0

180

1

7

0

1

6

0

15

0

14

0

1

3

0

1

2

0

110

1

0

0

9

0

8

0

7

0

6

0

4

0

2

0

0

34

0

1

0

0

90

80

7

0

60

50

4

0

30

2

0

10

110

13

0

120

140

150

350

PSI

BAR

R

1

3

4

a

M

C

1

2

3

4

5

6

7

8

9

10

1

8

0

0

1

0

-1

0

-20

-30

2

0

3

0

4

0

10

20

-

2

0

30

40

50

60

7

0

8

0

9

0

100

11

0

-40

F

I

n

Hg

VA

C

1

0

2

0

3

0

High

Low

V4

V5

R

VAC

LOWHIGH

REF

30

2

5

20

1

5

1

0

5

0

200

2

5

0

3

0

0

350

4

0

0

450

150

1

0

0

50

0

P

S

I

B

A

R

R

134a

M

C

40

60

50

7

0

8

0

3

0

2

0

1

0

0

190

1

8

0

1

7

0

1

6

0

1

5

0

140

1

3

0

1

2

0

11

0

1

0

0

9

0

80

7

0

6

0

40

2

0

0

34

0

100

90

80

70

60

50

40

30

2

0

1

0

110

13

0

120

140

1

5

0

350

PSI

B

A

R

R

1

3

4

a

M

C

1

2

3

4

5

6

7

8

9

1

0

1

8

0

0

10

-

1

0

-2

0

-30

2

0

30

40

10

20

-2

0

30

4

0

5

0

6

0

70

8

0

9

0

1

0

0

11

0

-

4

0

F

I

n

H

g

VAC

1

0

2

0

3

0

V10

V11

V16

V15

V2

V3

Access

Port

V1

V9

V6

V7

INLET

OUTLE

VALVE

English

Loading...

Loading...