headline bars

continuation tabs

notes

warnings

model no. 054-4892-4 | contact us 1-800-689-9928

16

SPEED SETTING (Fig. G)

The tool has a variable speed selector (4) for precise

speed adjustment with number “1” to “6”, the speed

can be adjusted from 8000 to 32000 RPM, the “6”

position is for the highest speed. Continue to dial the

variable speed selector to a higher mark and the speed

will increase accordingly.

Always choose the correct speed range for your work

according to the material. Determine the correct

speed for work on any material by practicing for a few

minutes on a piece of scrap.

Choose a low speed when working with wood, plastics

and polishing, and use the small tools with high speed

and the larger tools with slower speed. When working

with plastic, for example, start with slow speed and

increase the speed until you observe that the plastic is

melting at the point of contact, then reduce the speed

slightly to get the optimum working speed.

RECOMMENDED WORKING SPEED RANGE:

• Plastic and other materials that melt at low

temperatures should be cut with low speed.

• Polishing, buffing and cleaning with a wire brush

should use a medium speed of 15,000 RPM to

prevent damage to the brush and your material.

• Wood should be cut with high speed.

• Cut metal or mild steel with high speed. If a HSS

(high-speed steel) cutter starts with obvious

vibration, it usually indicates that it is running too

slow.

• Aluminum, copper alloys, lead alloys, zinc

alloys and tin should be cut with various speed,

depending on the type of cutting being done. Use

paraffin (not water) or other suitable lubricant on

the cutter to prevent the cut material from adhering to

the cutter teeth.

Fig. A

Collet

Collet nut

Fig. C

Fig. D

a

b

ON

OFF

Fig. E

Fig. F

Fig. G

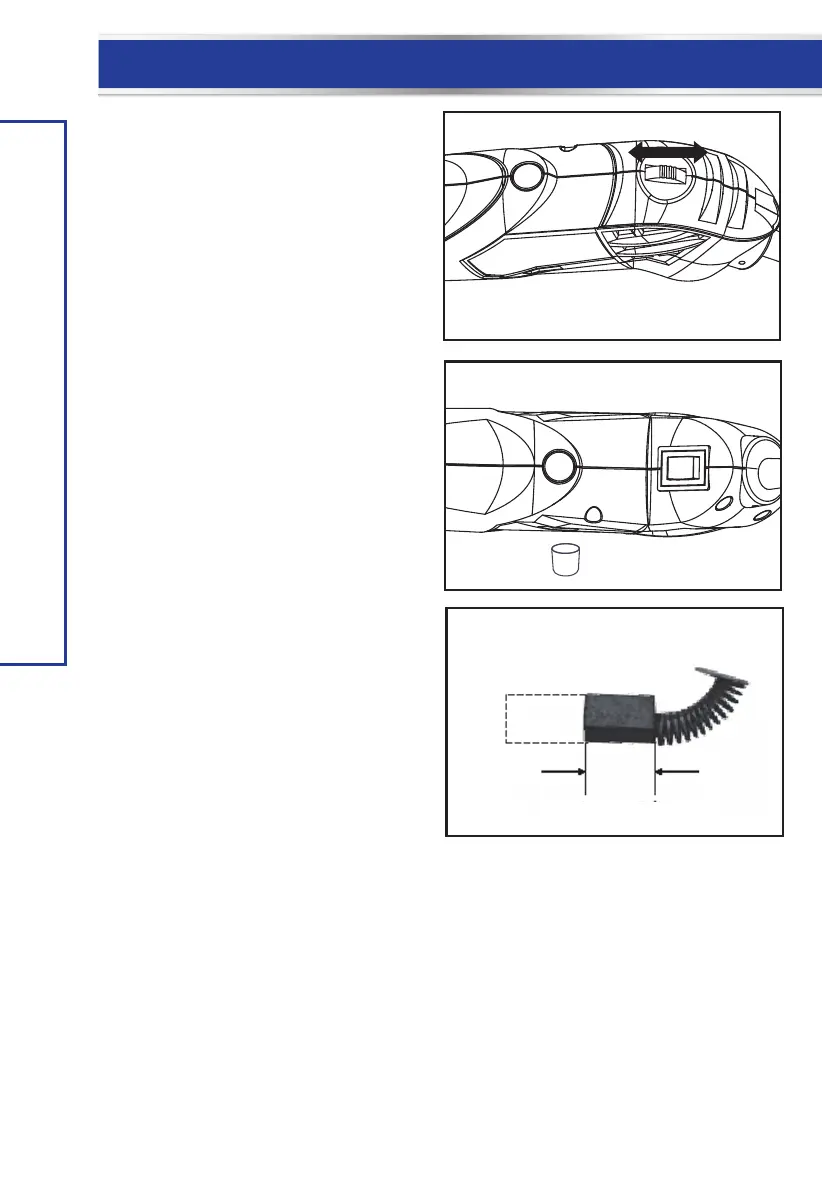

Fig. H

Fig. I

1/4" (6 mm)

OPERATING INSTRUCTIONS

Loading...

Loading...