headline bars

continuation tabs

notes

warnings

model no. 062-3408-6 | contact us 1-800-689-9928

18

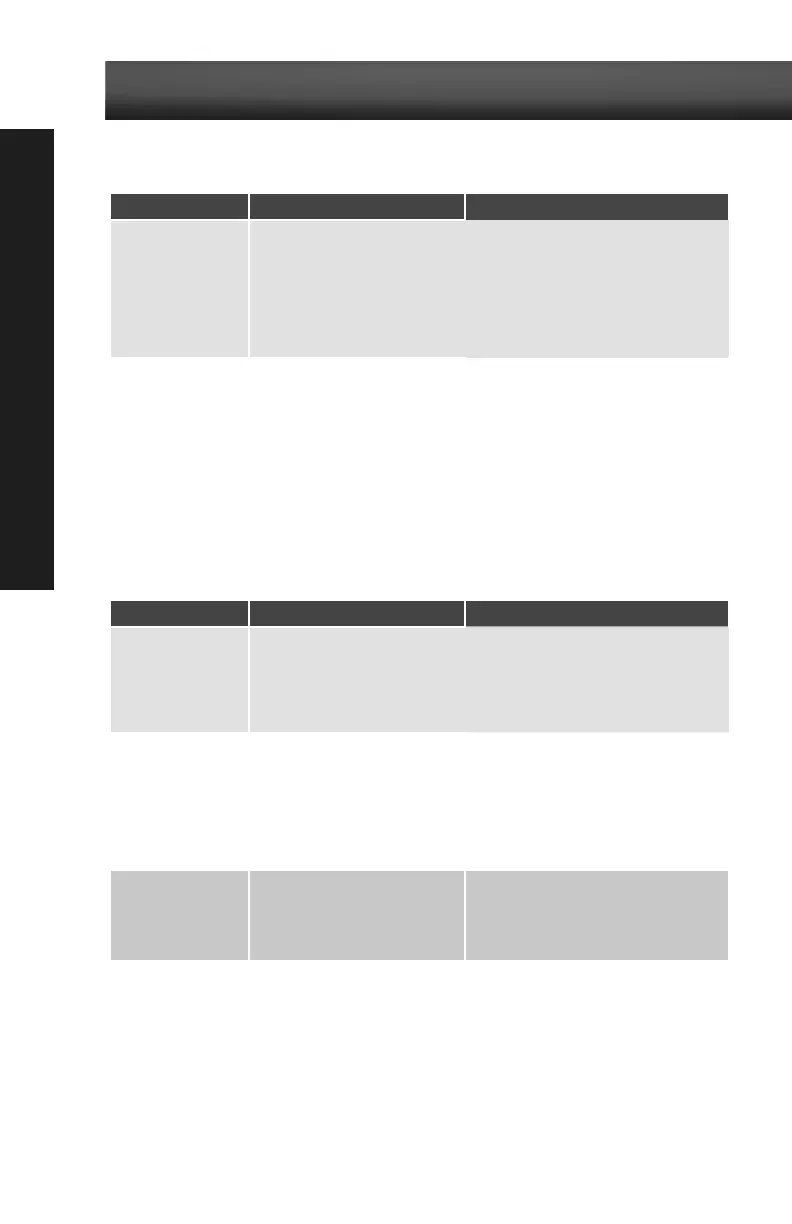

SUBMERSIBLE UTILITY PUMP FUNCTION

Problem Possible Causes Corrective Action

Pump does not start

or run.

1. The fuse is blown.

2. The breaker is tripped.

3. The plug is disconnected.

4. The plug is corroded.

5. The motor failed.

6. Ice or blockage has locked the

impeller.

1. Replace the fuse.

2. Reset the breaker.

3. Secure the plug.

4. Clean the plug prongs.

5. Replace the pump.

6. Remove the blockage.

Pump cannot pump

water out.

1. The screen is blocked.

2. The hose is kinked, bent sharply,

or coiled.

3. There is an airlock.

4. The impeller is loose on the shaft.

5. The impeller is broken.

1. Clean the screen.

2. Straighten the hose.

3. Clean the anti-airlock hole.

4. Reassemble the impeller.

5. Replace the impeller.

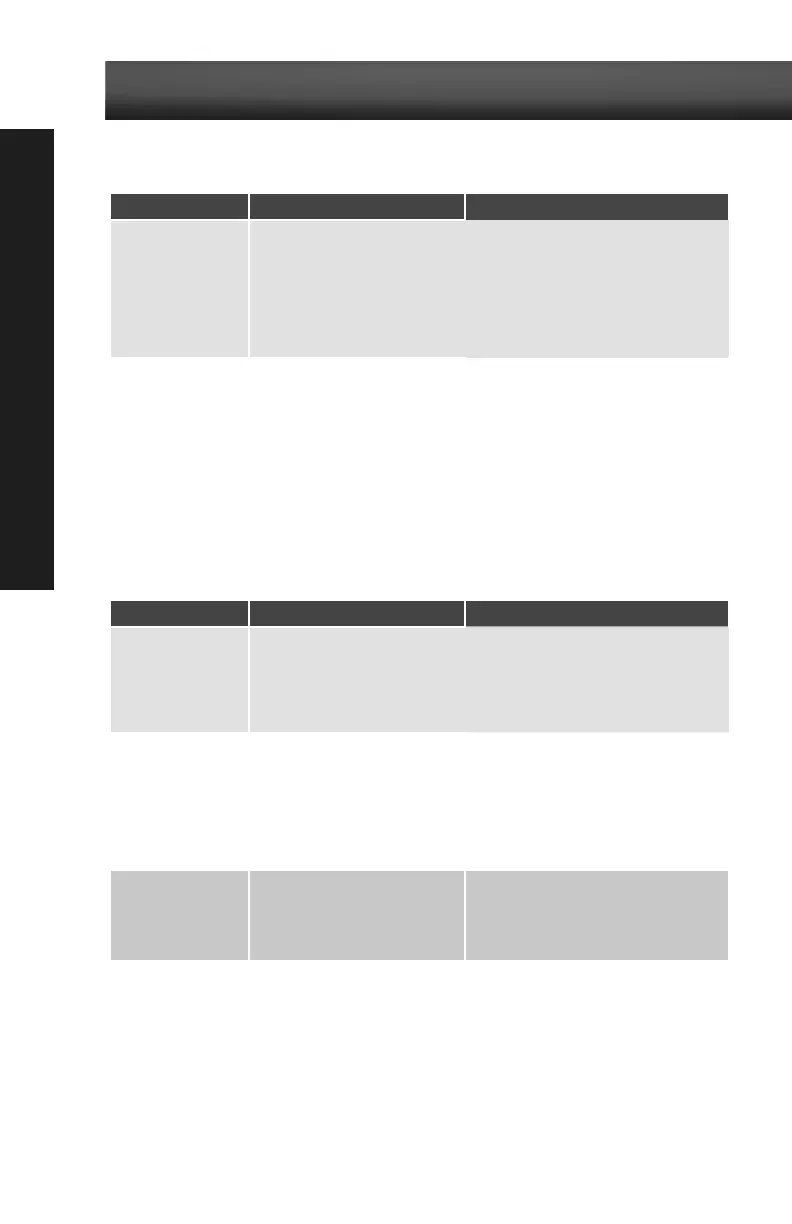

NON-SUBMERSIBLE TRANSFER PUMP FUNCTION

Problem Possible Causes Corrective Action

The pump does not

start or run.

1. The fuse is blown.

2. The breaker is tripped.

3. The plug is disconnected.

4. The plug is corroded.

5. The motor failed.

1. Replace the fuse.

2. Reset the breaker.

3. Secure the plug.

4. Clean the plug prongs.

5. Replace the pump.

The pump does not

prime.

1. The suction line has an air leak.

2. The impeller is clogged.

3. Did not fill water into inlet hose.

4. Did not attach the suction strainer

with built-in check valve to inlet hose.

1. Repair suction line by tightening hose

connection or replacing hose washer if

necessary.

2. Remove the blockage.

3. Add water to the pump and inlet hose.

4. Attach the specially designed factory-

supplied suction strainer to hose end.

The flow rate is too

low.

1. The hose is kinked or coiled.

2. The strainer or hose is blocked.

3. The discharge hose is too long.

4. The impeller is broken.

1. Straighten the hose.

2. Clean the strainer or hose.

3. Shorten the hose to 50' (15.2 m ) max.

4. Replace the impeller.

TROUBLESHOOTING

Loading...

Loading...