Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

0.6 Manuale Istruzioni GN UTEC B041.M01.EN 28/47 07/2014

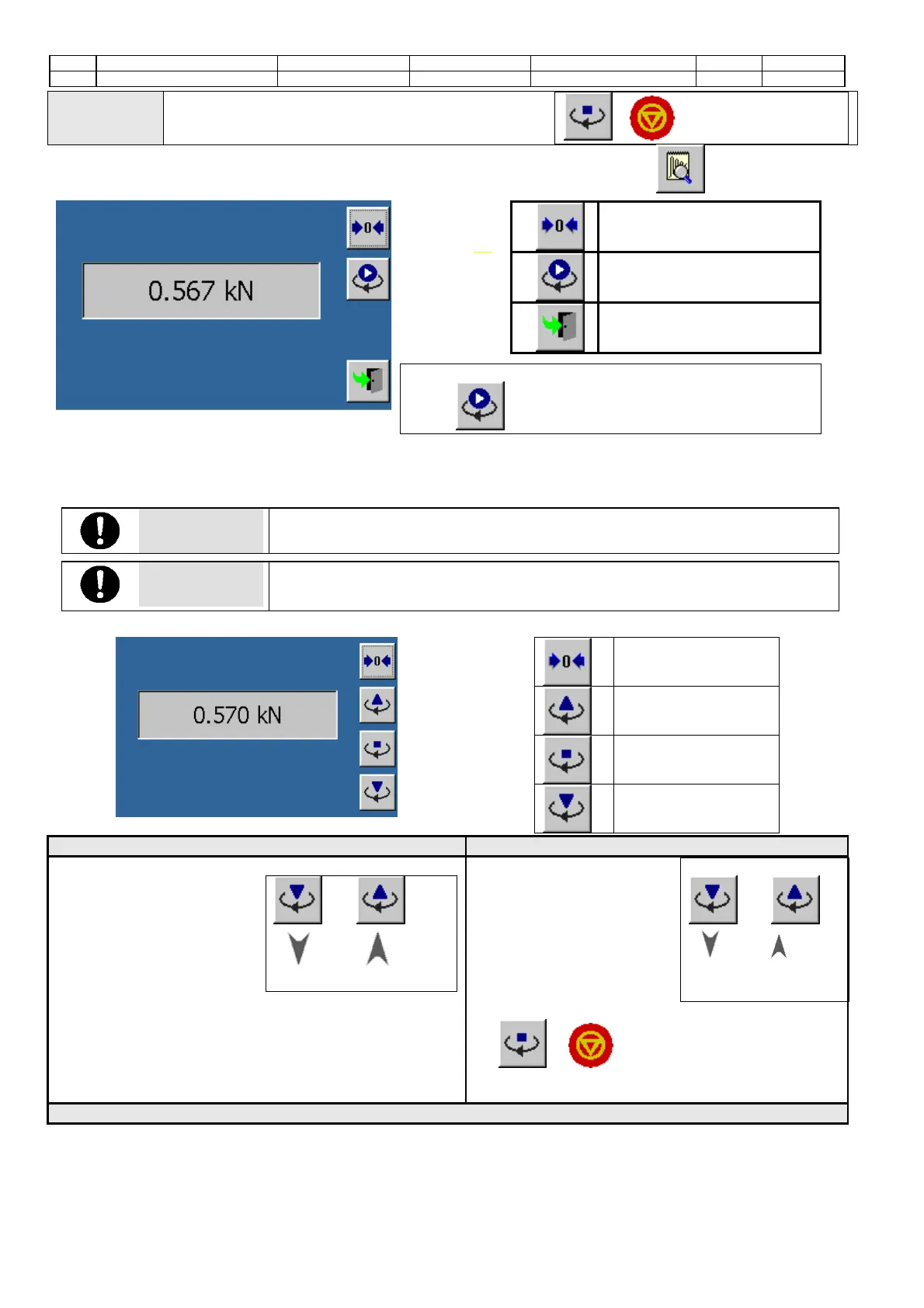

4. Stop the manual activation by pressing the button

or key-pad.

It is also possible to check the correct calibration of the analog channel using the button .

Commands

Readout zeroing

Start the manual

activation

Screen closure

When the manual activation is started (by pressing the

button ) the machine:

• enters immediately the manual mode (in case of calibration of the gyration angle channel or of the specimen

height channel);

• moves the piston downwards until it touches the standard cell previously positioned into the machine (in case

of calibration of the applied load channel).

ATTENTION

The manual activation function must be activated only by professional and experienced

staff, as this operation may damage/break the machine.

ATTENTION

The manual activation for the control of the gyration angle channel and applied load

channel calibration, can be activated only if the specimen height channel has been

previously set and calibrated.

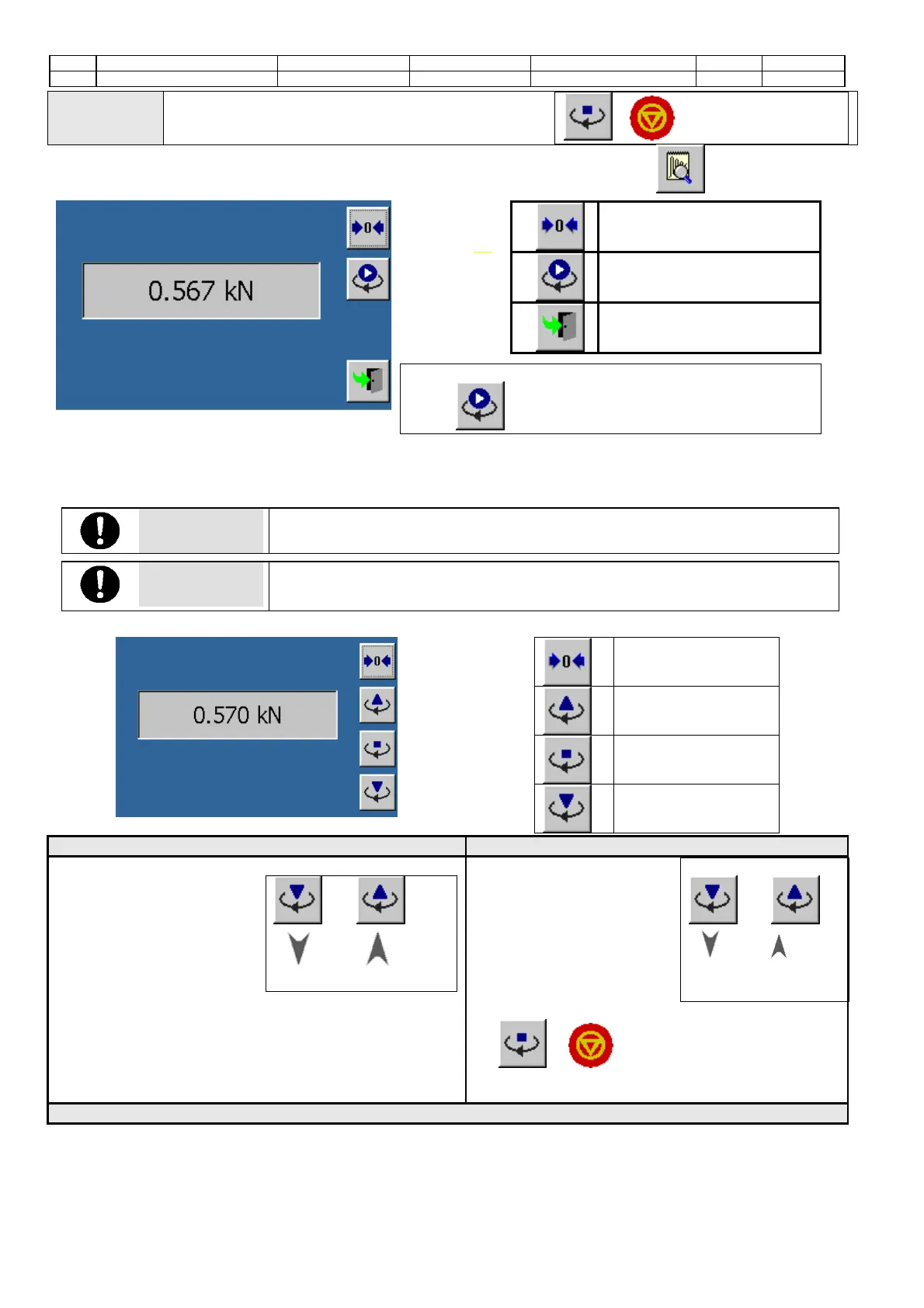

The screen of the calibration check will be as follows:

Readout zeroing

To move the piston

upwards

To stop the manual

activation

Tomove the piston

downwards

Calibration of the gyration angle channel: Calibration of the specimen height channel:

1. Position the mould.

2. Press these buttons to

move the piston upwards

and downwards until it

touches the mould

and or

( and key-

pad)

3. Perform a manual rotation until the minimum

positioned is reached.

4. Position the distance pieces of different dimensions

and check the corresponding readouts.

5.

Repeat the operations described at points 3 and 4

until all the calibration steps are set.

1. Press these buttons to

move the piston

downwards/upwards until

it rests on the distance

pieces of different

dimensions; then check

the corresponding

readouts.

and or

( and when

using the key-pad)

2. Stop the manual activation by pressing the button

or when using the key-pad.

Calibration of the applied load channel:

Loading...

Loading...