Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

03 Manuale Istruzioni Ufficio Tecnico Resp.Tecnico C314.M01.EN.03

10/18

03/2009

10

For any special maintenance operation (repairs, replacements or any other operation not described in this manual),

please ask the manufacturer

Chapter 8 DIAGNOSIS

Some easy to solve and simple problem, which can happen during the working of the appliance, are introduced in this

chapter.

ATTENTION

All maintenance, checking, control and repairing operations of each part of the machine or of the electric

system, must be carried out by skilled operators instructed about the functions and working procedures

of the appliance.

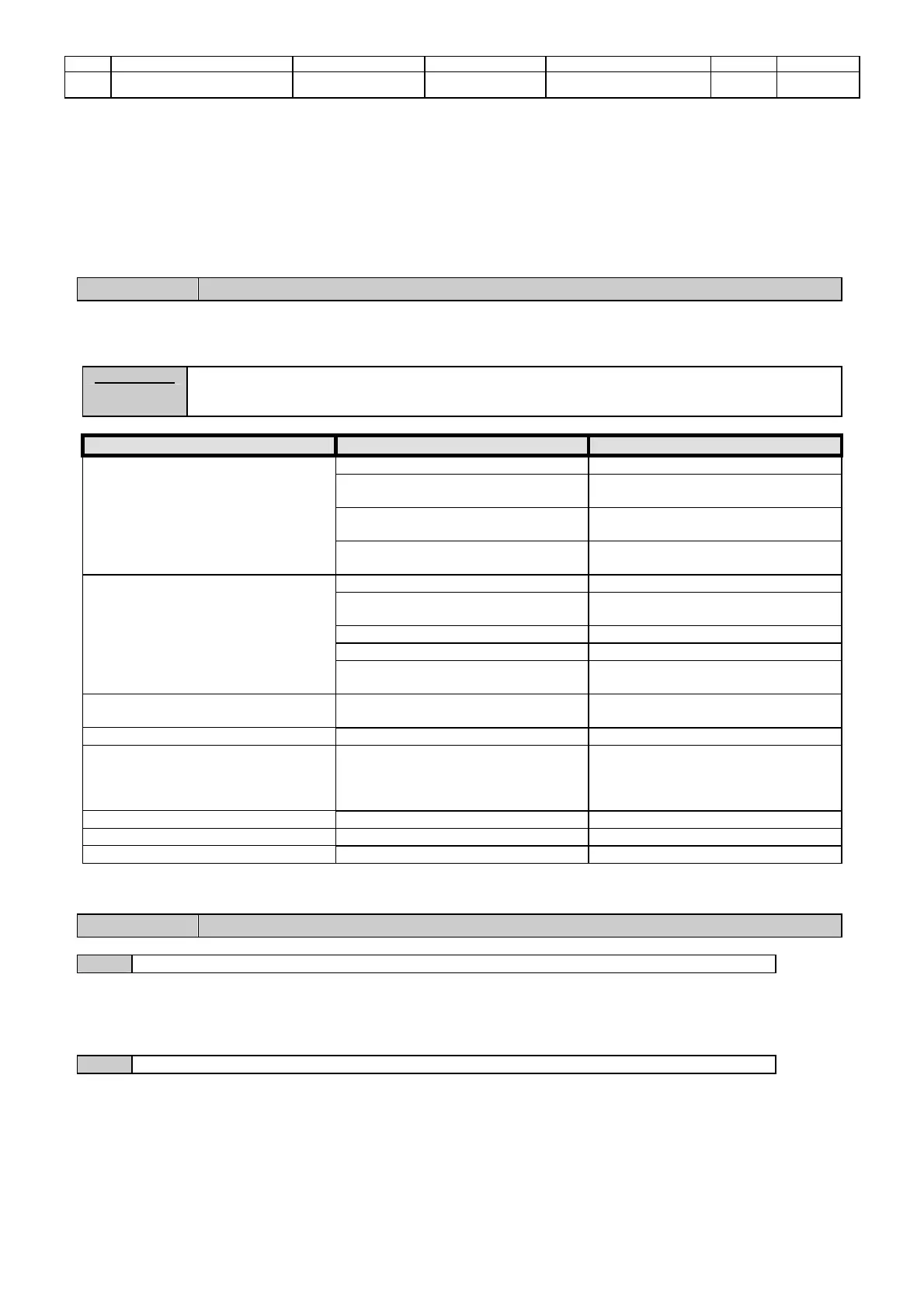

FAILURE POSSIBLE CAUSE CURE

The machine doesn’t turn on No main supply Check the right switching on

Check that there is electricity on the

main board

Fuses have broken Replace the broken fuses with same

capacity ones

The safety stop has gone on because

of the high temperature

Contact the After Sales Service

The set humidity is not reached No water supply Check the water feeding

Ventilation and Climax are not on Turn them on by the relative push-

buttons

Improper setting of the regulator Check the introduced value

The boiler is not heating Check the fuses

The steam solenoid is not working

properly

Check the proper working of the

solenoid and check the fuse.

The inner temperature is too high The temperature Controller has not

been set correctly.

Check the temperature Controller has

been set correctly.

The door is not perfectly close Check the door has been closed

The equipment is too noisy The equipment has not a correct

levelling.

Check the equipment has been

levelled correctly in order to avoid

vibrations caused by a wrong

stabilization.

The door is not perfectly close Check the door has been closed

High level of condensation The environment moisture is too high

The door is not perfectly close Check the door has been closed

Chapter 9 SCRAPPING

9.1 SETTING ASIDE

In case of setting aside for a long time it is necessary to disconnect the electric feeding.

Execute all the maintenance operations.

Oil the parts that are not varnished and cover the machine against the dust.

9.2 SCRAPPING

When the machine is not used anymore, it is recommended:

• to disconnect the cable of the feeding

• Cover/destroy all the parts which may be dangerous as cutting, projecting or sharpened ones.

• Disassemble the machine and scrap it as per the actual laws.

Loading...

Loading...