9

CHAPTER 5

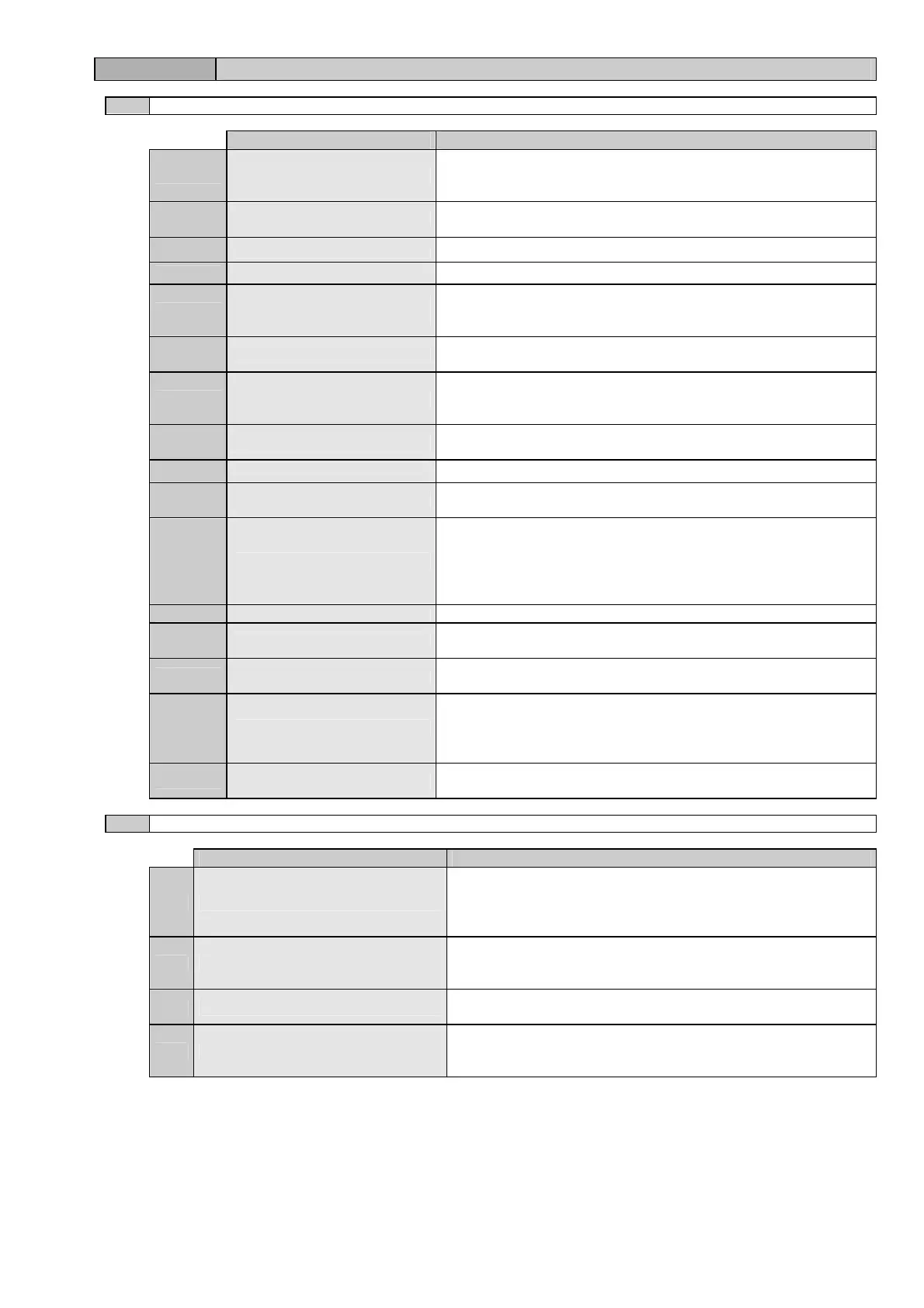

CONTROL DESCRIPTION

B1 / C1

BEATER

It allows mixing water, cement and sand into the bowl (

order to get the desired quality of mortar. Its turning

movement achieves the mixing action.

B2

HOPPER

It allows collecting the sand. Going through the membrane

(B3) the sand falls into the bowl (B14).

B3

MEMBRANE It connects the hopper (B2) to the bowl (B14).

B4 / C4

ELECTRIC MOTOR It allows turning the beater (B1) inside the bowl (B14).

B5 / C5

FIXING SCREWS OF THE

UPPER CARTER

They allow securing the upper carter to the sheet frame (

Removing it, the operator can easily inspect or maintain the

inside components of the mixer.

B6 / C6

ROTATION PIN

It allows the beater rotation (

thanks to a reducer, directly to the electric motor (B4).

B7 / C7

LEVER

Using it the operator can free the bowl stop (

the removing of the bowl. To block it once again put the lever

back to its original position.

B8 / C8

SPRING

Together with the bayonet fitting on the tang (

block the tang itself to the rotation pin (B6).

B9 / C9

SHEET FRAME It is the main structure of the whole appliance.

B10 / C10

BOWL STOP

It allows blocking the bowl (

) in the position selected by

using the fixing device (

).

B11 / C11

FIXING DEVICE

) it blocks the bowl in the mixer

special housing. This fixing device is provided with notches to

regulate the bowl position. This is extremely important to keep

the minimum distance of 3 mm between the beater (B1) and

the inner walls of the bowl (B14) as required by the Specifics.

B12 / C12

TANG

up of the beater to the rot

B13/ C13

MAIN SWITCH

It allows switching the appliance on and off. If necessary it

also acts as emergency switch.

B14 / C14

BOWL

It collects the sand making the mixture with water and cement

possible. A special grip grants an easy handling of the bowl.

B15 / C15

GREASING DEVICE

It helps the operator during the maintenance procedures

(greasing of the internal rotating components). To reach the

greasing device, just remove the upper carter undoing the

fixing screws (B5).

B16

PROTECTION CARTER

It protects the operator from the dangers coming from the

beater rotation and from the internal rotating components.

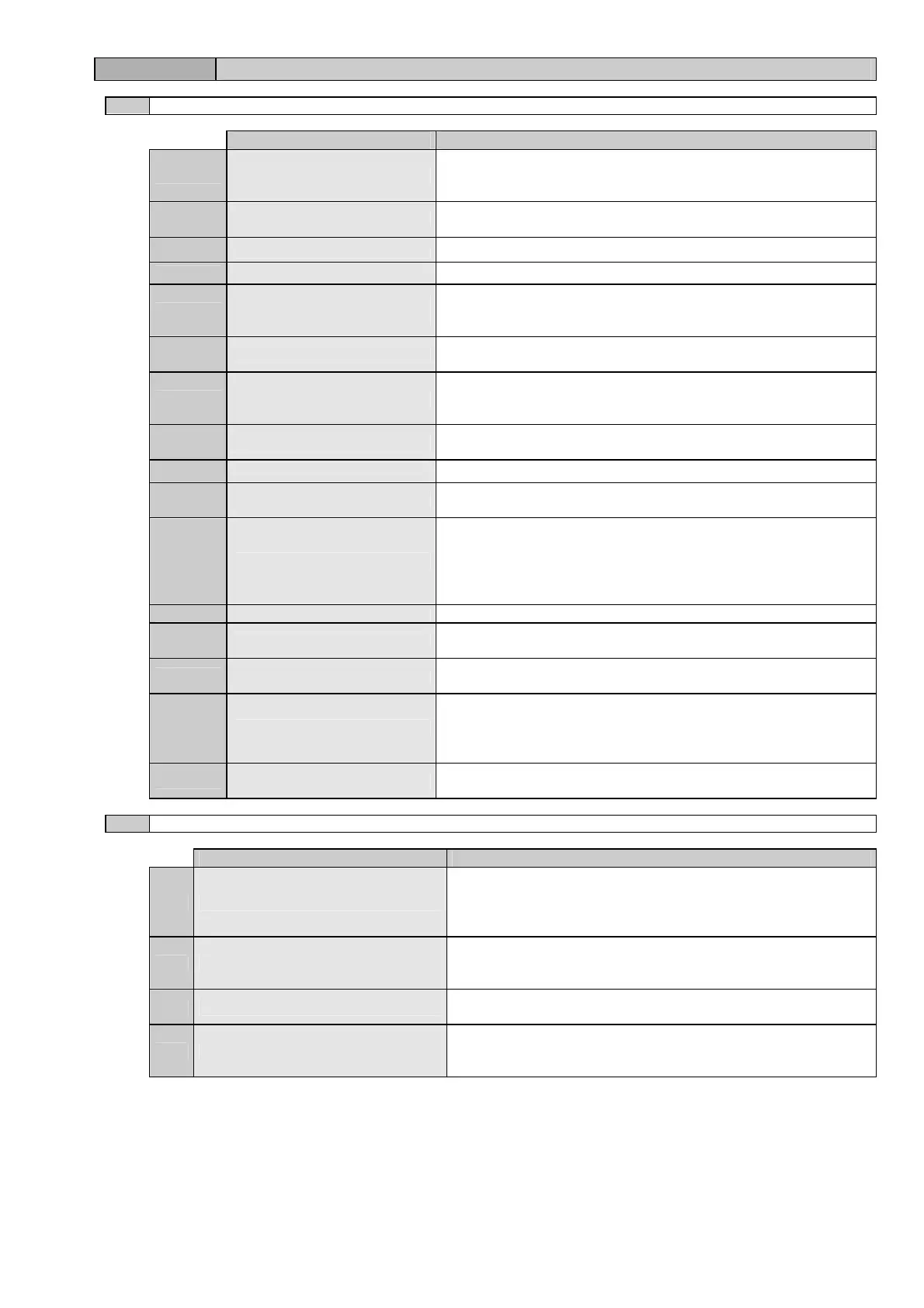

CONTROL DESCRIPTION

E1

SPEED SELECTOR

Activating this switch, it is possible

turning speed of the beater (B14). To start the turning, press

the button START (E2); furthermore it is possible to change

the speed without stopping the test.

E2

START PUSH BUTTON

Pressing this button, the appliance starts (only mot

rotation) in accordance to the pre-selected speed made

using the switch (

).

E3

STOP PUSH BUTTON

Pressing this button, the beater turning is interrupted. To

continue the turning, press the button START (E2).

E4

FUNCTION SELECTOR

r, it is possible to choose between two

different turning modes (slow or fast). It is also possible to

stop the turning.

Loading...

Loading...