13

OPERATION

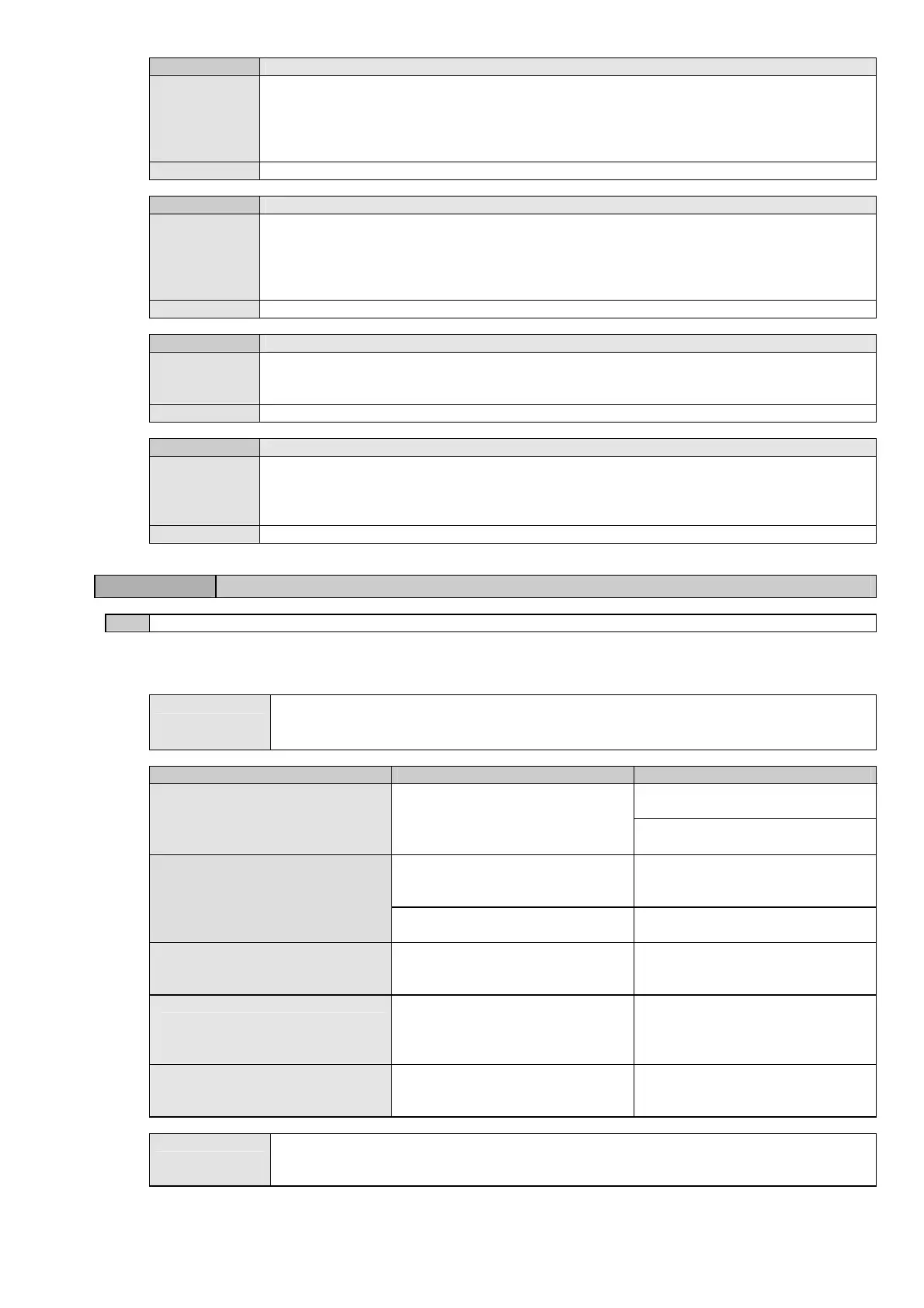

CHECK OF THE SAFETY CAGE (B16)

PROCEDURE

Verify after 30 working hours the conditions of the safety disposals which form the

safety cage B16); in case of bad working conditions repair or replace the parts

immediately.

Clean the surfaces of the magnet plaques from any mortar dirty, in order to grant the

perfect closing of the door.

FREQUENCY

EVERY 30 WORKING HOURS

OPERATION

GREASING OF THE ROTATING COMPONENTS

PROCEDURE

se every 250 working hours the gears for beater rotation, which are placed inside

the frame sheet. Use complex lithium grease suitable for high temperatures. To remove

the upper carter, undo the special fixing screws (B5 / C5) on both mixer sides. Then

introduce the grease using the special fitting for greasing device (B15 / C15). You can

find it on the machine.

FREQUENCY

EVERY 250 WORKING HOURS

OPERATION

CHECKING THE MEMBRANE CONDITIONS (

)

PROCEDURE

Periodically check the wear and tear conditions of

the membrane. In fact cuts or

abrasions could be provoked by the normal use and by the sand flowing. If necessary

immediately replace it.

FREQUENCY

6 MONTHS

OPERATION

BOWL POSITIONING (B14 / C14)

PROCEDURE

The standard EN 196/1 states that a minimum di

stance of 3 mm ± 1 mm must be left

between the inside walls of the bowl (B14 / C14) and the beater. Since the beater (B1 /

C1) is made of material, which is subject to wear and tear, it is possible to modify the

bowl position by using the special notches of the fixing device. (

/

).

FREQUENCY

EVERY 100 WORKING HOURS

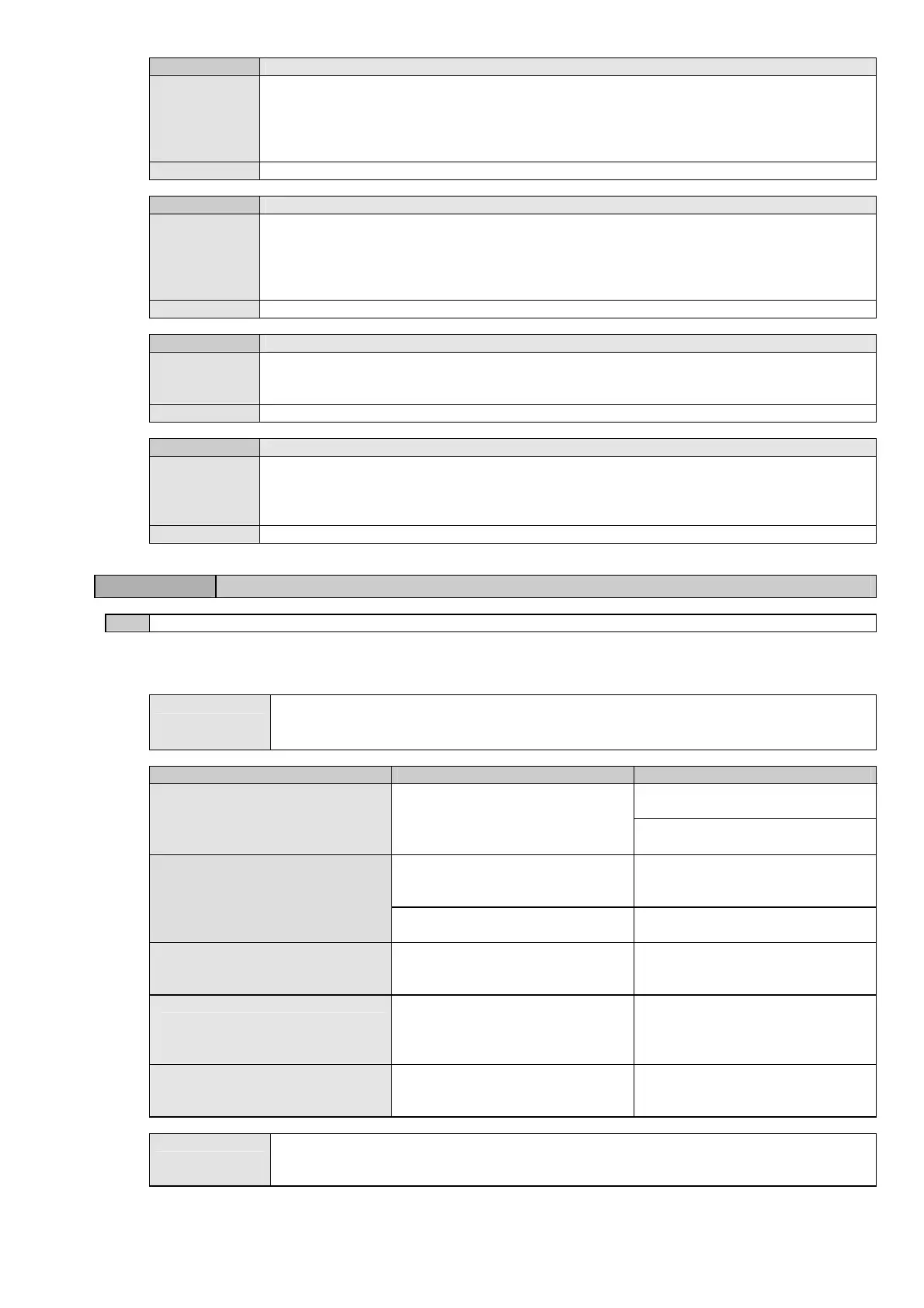

CHAPTER 8

Some easy to solve and simple problem, which can happen during the working of the appliance, are

introduced in this chapter.

ATTENTION

All maintenance, checking, control and repairing operations of each part of the

machine or of the electric system, must be carried out by skilled operators instructed

about the functions and working procedures of the appliance.

After the activation of the Main

switch, the appliance doesn’t

start.

No supply

Check the correct use of the

Main Switch

Verify the Main in the Panel

The beater (B1 / C1) doesn’t

turn

The inside mechanisms for the

beater movement are broken or

too worn out

Contact the After Sale Service

Failure to the electric motor

(B4/C4)

Contact the After Sale Service

The lever (B7 / C7) doesn’t go

down or doesn’t come back to

the original position

The inside components for lever

movement are broken or too

worn out

Contact the After Sale Service

The safety door (B16) doesn’t

close

The magnet surfaces to close the

carter are dirty or damaged

Clean the blocking plates

carefully. In the event they are

too damaged or worn out Contact

our After Sale Service

When opening the safety door

(B16), the Mixer doesn’t stop

Failure to the electric system

Check if the wires and the

connections of the electric circuit

are interrupted.

ATTENTION

Contact our After Sale Service for any other problem not listed or in the event the

problem remains even after the operator’s intervention according to the instructions

given above.

Loading...

Loading...