15

ENGLISH

MAINTENANCE

1. Any and all part removal or replacement must be performed by a qualified service technician.

2. DO NOT use any equipment that is damaged and or has worn or broken parts.

Use only replacement parts supplied by your country’s local MATRIX dealer.

3. MAINTAIN LABELS AND NAMEPLATES: Do not remove labels for

any reason. They contain important information. If unreadable or

missing, contact your MATRIX dealer for a replacement.

4. MAINTAIN ALL EQUIPMENT: Preventative maintenance is the key to

smooth operating equipment as well as keeping your liability to a

minimum. Equipment needs to be inspected at regular intervals.

5. Ensure that any person(s) making adjustments or performing maintenance or

repair of any kind is qualified to do so. MATRIX dealers will provide service

and maintenance training at our corporate facility upon request.

B

A

MAINTENANCE SCHEDULE

ACTION FREQUENCY

• Turn o the bike by unplugging the power cord from the wall

outlet

• Wipe down the bike with a damp cloth. Never use solvents,

as they can cause damage to the bike.

• Inspect the power cord. If the power cord is damaged, contact

Customer Tech Support fora replacement.

• Make sure the power cord is not underneath the bike or in

any other area where it can become pinched or cut.

AFTER EACH USE

Make sure that the indoor cycle is level and does not rock. DAILY

• Turn o the bike by unplugging the power cord from the wall

outlet.

• Clean entire machine using water and a mild soap or other

Matrix approved solution (cleaning agents should be alcohol

and ammonia free).

• Clean all exterior parts, the steel frame, front and rear

stabilizers, seat and handlebars.

WEEKLY

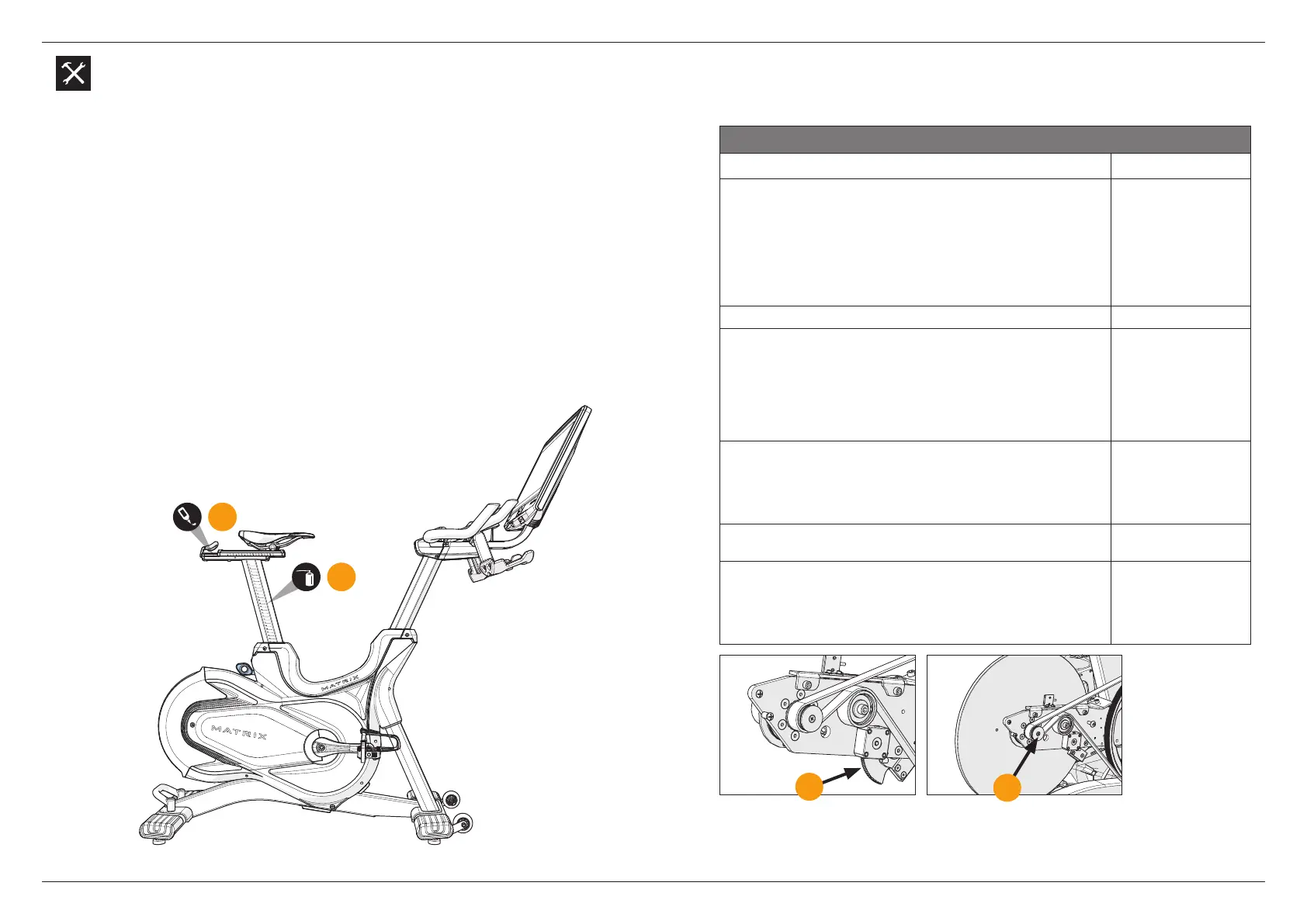

Lubricate the saddle post (A). To do this, raise the saddle post to

the MAX position, spray with maintenance spray and rub down

the entire exterior surfaces with a soft cloth. Clean the saddle

slide (B) with a soft cloth and if necessary apply a small amount

of lithium/silicone grease.

BI-WEEKLY

Inspect all assembly bolts and pedals on the machine for proper

tightness.

MONTHLY

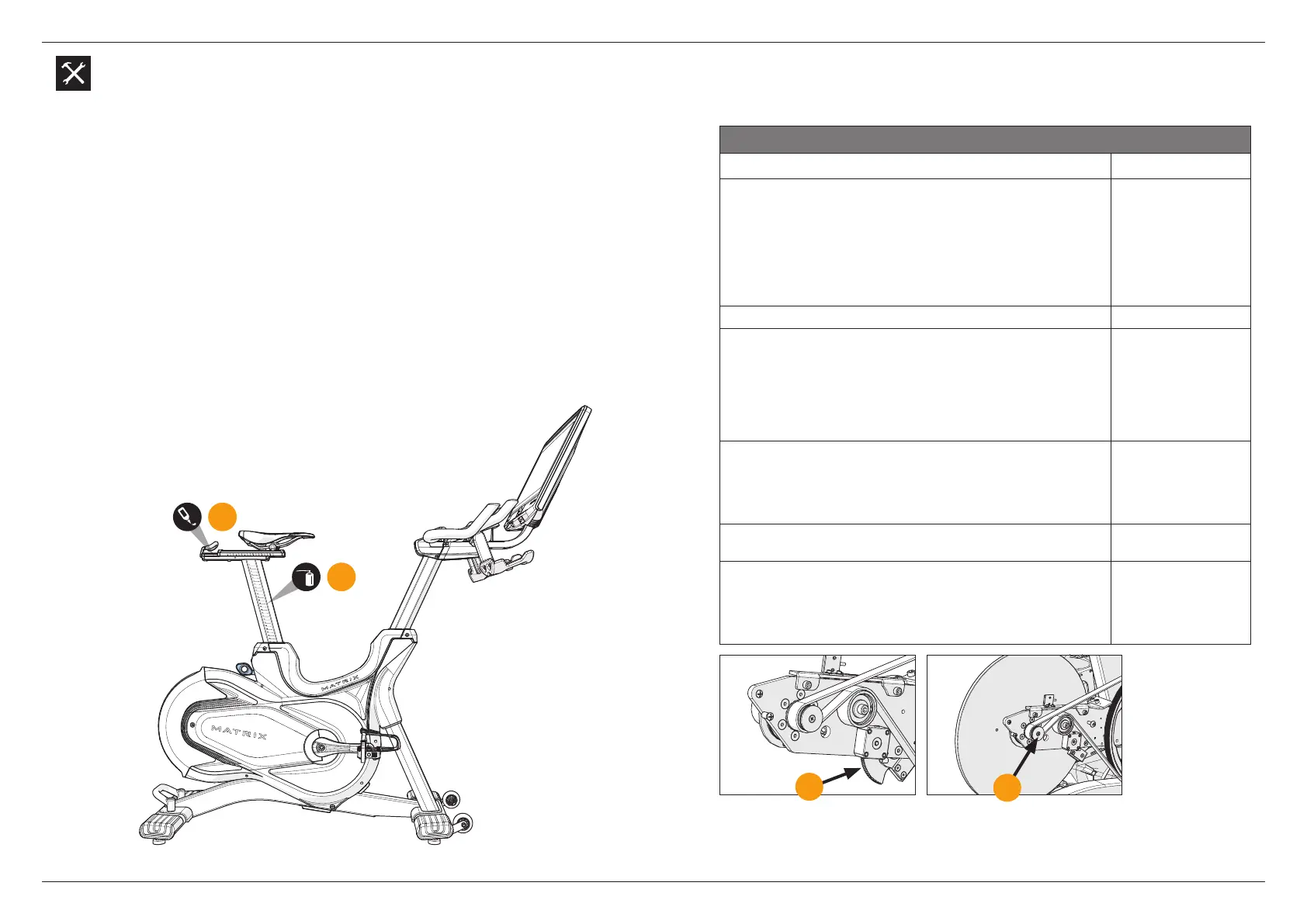

• Remove right service panel. Rotate the break assembly

counterclockwise until it hits the hard stop. Clean gear of old

grease and re-apply a lithium-based grease to gear teeth (C).

• Remove right service panel. Unfasten flywheel clutch cap and

remove wavy washer. Wipe o belt debris and reinstall (D).

6 MONTHS

C

D

Loading...

Loading...