7

2. SPECIFICATIONS AND TECHNICAL DATA

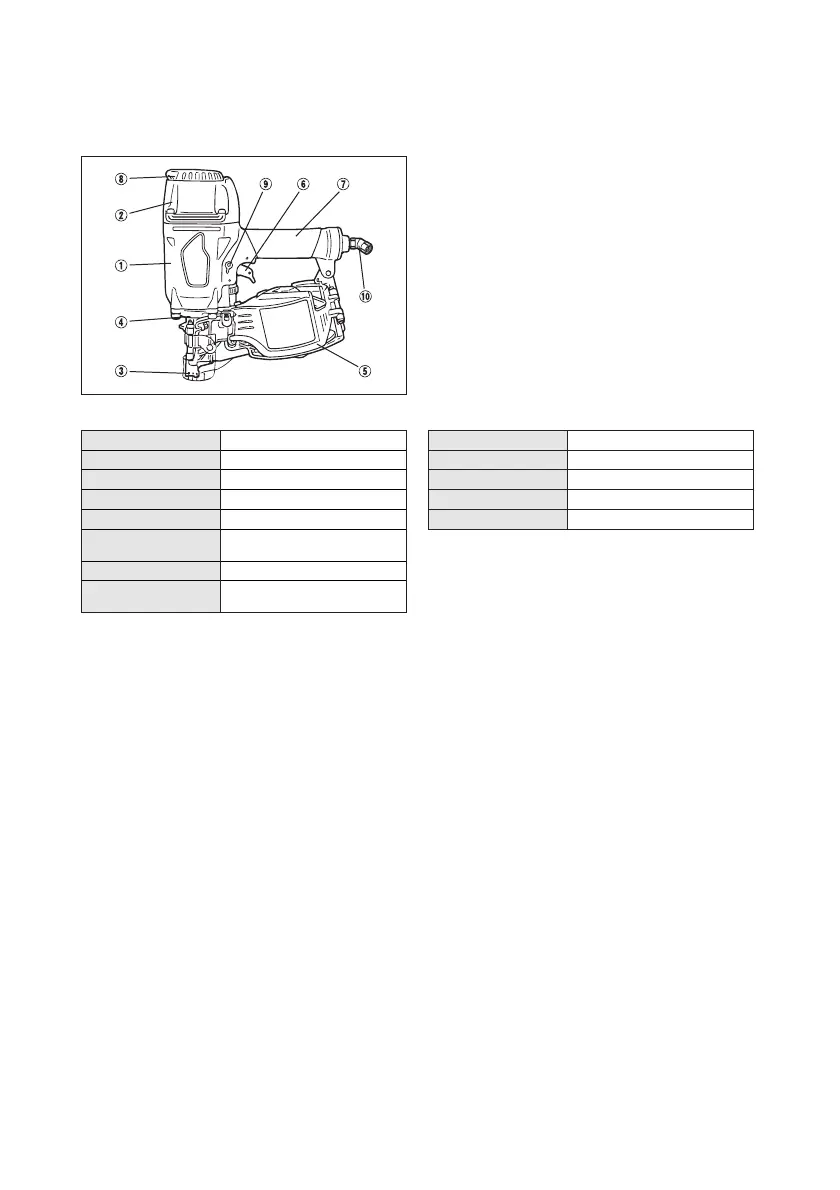

1. NAME OF PARTS

2. TOOL SPECIFICATIONS

PRODUCT NO. CN665D

HEIGHT 12-5/8˝ (321 mm)

WIDTH 5˝ (130 mm)

LENGTH 11˝ (280 mm)

WEIGHT 6.2 lbs. (2.8 kg)

RECOMMENDED

70 to 100 p.s.i. (5 to 7 bar)

OPERATING PRESSURE

LOADING CAPACITY 300 Nails

AIR CONSUMPTION

1.20Rat 90 p.s.i. (6 bar)

operating pressure

q

Frame

w

Cylinder Cap

e

Contact Arm

r

Nose

t

Magazine

y

Trigger

u

Grip

i

Exhaust Cover

o

Trigger Lock Dial

!0

Swivel Joint

3. FASTENER SPECIFICATIONS

PRODUCT NO. CN665D

NAIL LENGTH 1-1/2˝ to 2-1/2˝ (38 to 65 mm)

SHANK DIAMETER

.092˝ to .131˝ (φ2.3 to φ3.3 mm)

SHANK TYPE Smooth, Ring, Screw

HEAD DIAMETER

.224˝ to .276˝ (φ5.7 to φ7.0 mm)

TOOL AIR FITTINGS:

This tool uses a 1/4˝ N.P.T. male plug. The inside diameter should be .28˝ (7mm) or larger. The fitting must be capable of

discharging tool air pressure when disconnected from the air supply.

RECOMMENDED OPERATING PRESSURE:

70 to 100 p.s.i. (5 to 7 bar). Select the operating air pressure within this range for best fastener performance.

DO NOT EXCEED 120 p.s.i. (8 bar).

4. TECHNICAL DATA

q

NOISE

A-weighted single-event ------ LWA, 1s, d 94.99 dB

sound power level

A-weighted single-event ------ LpA, 1s, d 88.00 dB

emission sound pressure

level at work station

IThese values are determined and documented in accordance to EN12549:1999+A1:2008.

NOTE: These values are tool-related characteristic values and do not represent the noise generation at the point of use. Noise

at the point of use will for example depend on the working environment, the workpiece, the workpiece support, and the number

of driving operations. In addition, reference should be made to noise reduction measures.

NOTE: Workplace design can also serve to reduce noise levels, for example placing workpieces on sound-damping supports

(see also ISO11690-1).

w

VIBRATION

Vibration characteristic value = 4.30 m/s

2

These values are determined and documented in accordance to ISO 28927-13

NOTE: The vibration emission value above is a tool-related characteristic value and does not represent the influence to the

hand-arm-system when using the tool. Any influence to the hand-arm-system when using the tool will for example depend on

the gripping force, the contact pressure force, the working direction, the adjustment of energy supply, the workpiece, the

workpiece support.

5. APPLICATIONS

*General constuction works including panel sheathing, decking, subflooring, siding

Loading...

Loading...