10.4 Connection diagram of the system

1. Outdoor unit

2. Indoor unit

3. Gas pipe side (higher diameter)

4. Liquide pipe side

5. Draining pipe

6. Siphon

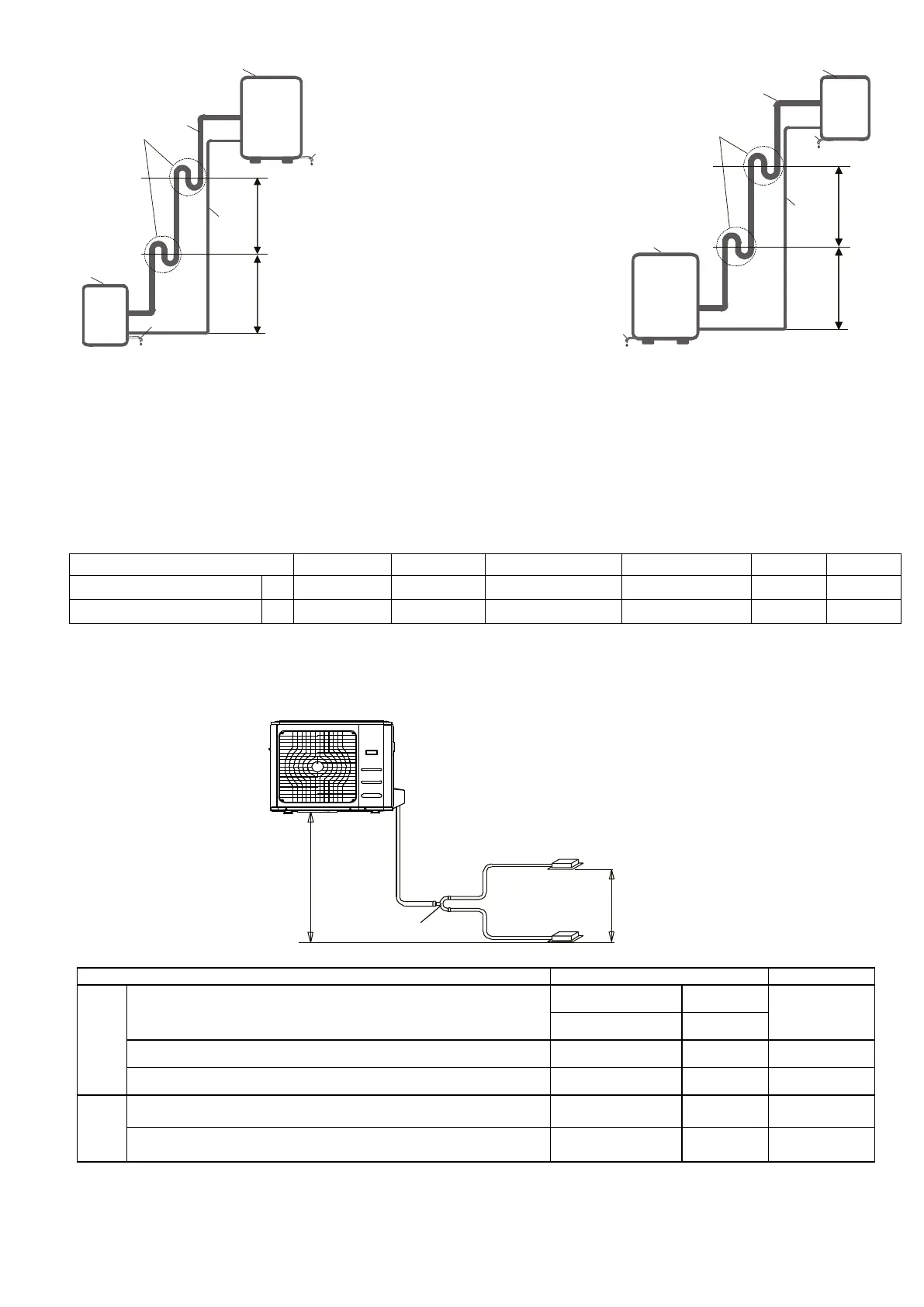

■ Outdoor unit above and indoor unit below

In this case, the inlet pipe (3) must be provided with

siphons (6) every 6 meters of level difference. These

siphons are to enable the return of the oil to the

compressor. The connection pipes must be insulated.

■ Outdoor unit below and indoor unit above

In this case, a siphon (3) must be crea

intake pipe (6) every 10 meters to block the flow of

refrigerant and thus to avoid return of liquid to the

compressor.

The connection pipes must be insulated.

N.B.: The maximum height difference between the indoor and the outdoor units must not exceed the values indicated

in the below table.

Max. refrigerant pipe length m 30 50 65 65 65 65

Max. difference in level m 20 25 30 30 30 30

Attention: Wrappipe insulating material around the joint and secure it with plastic straps to avoid condensation

forming at the joints.

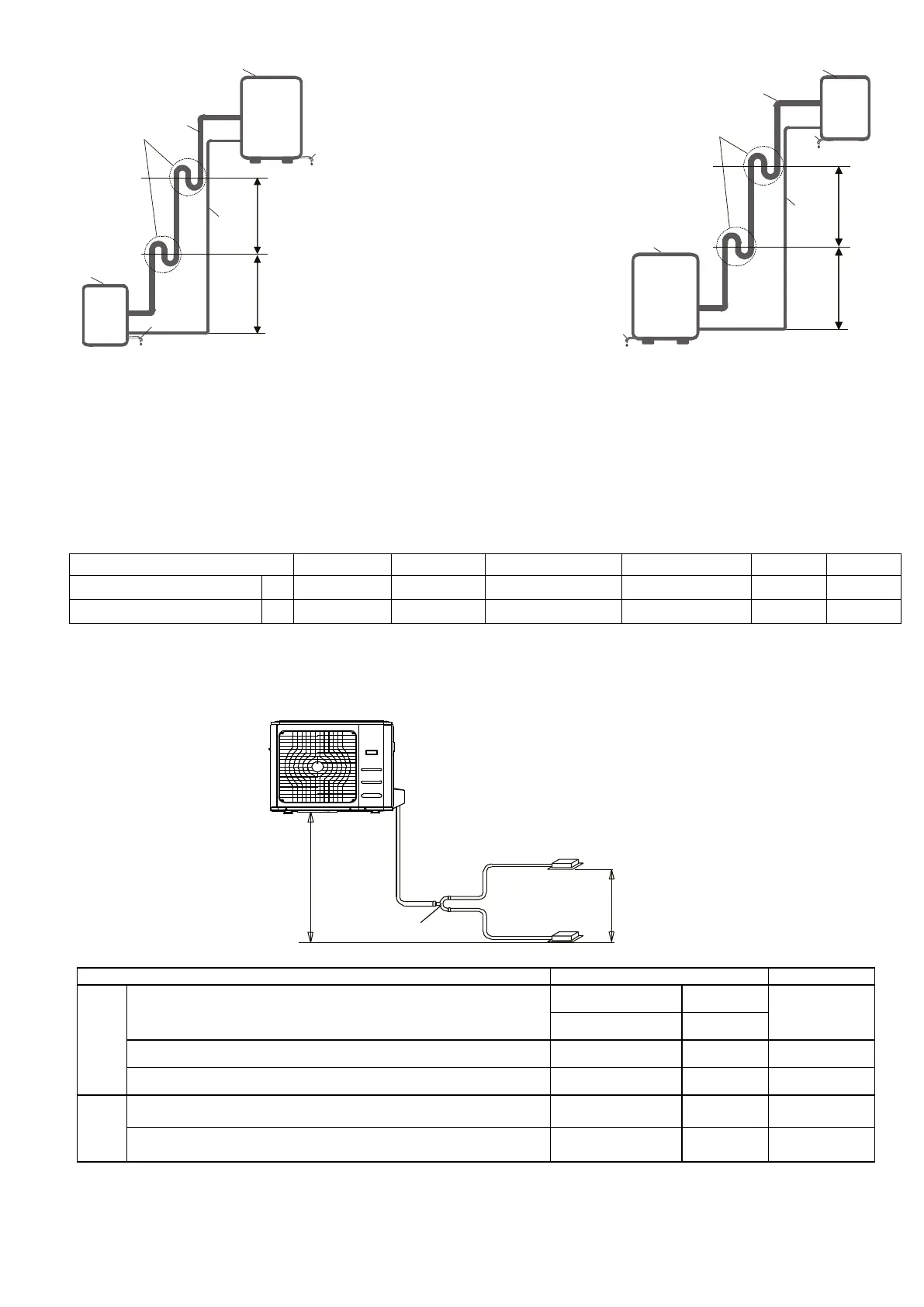

■ Outdoor units with TWIN function (on some models)

L

L1

L2

H2 ≤20m

The line branch pipe

Indoor unit

Outdoor unit

H1≤0.5m

Indoor unit

Pipe Length

Total pipe length (Actual)

5300 W + 5300 W 30m

L+Max(L1,L2)

7100 W + 7100 W 50m

Max. branch pipe length 15m L1, L2

Max. branch pipe length difference 10m L1-L2

Drop

Height

Max. height difference between indoor unit and outdoor unit 20m H1

Max. height difference between indoor units 0.5m H2

The branching pipe must be installed horizontally, error angle of it should not large than 10°. Otherwise, malfunction

will be caused.

25

Loading...

Loading...