• Select copper pipes for gas and liquid, as indicated in the relative table (see the specifications of the refrigerant

pipes table).

• Before assembling the pipe and its insulation, cover both ends of the pipe to protect it from dust and moisture.

• Try to avoid bending the pipes. If necessary, the radius of curvature can be over 100mm.

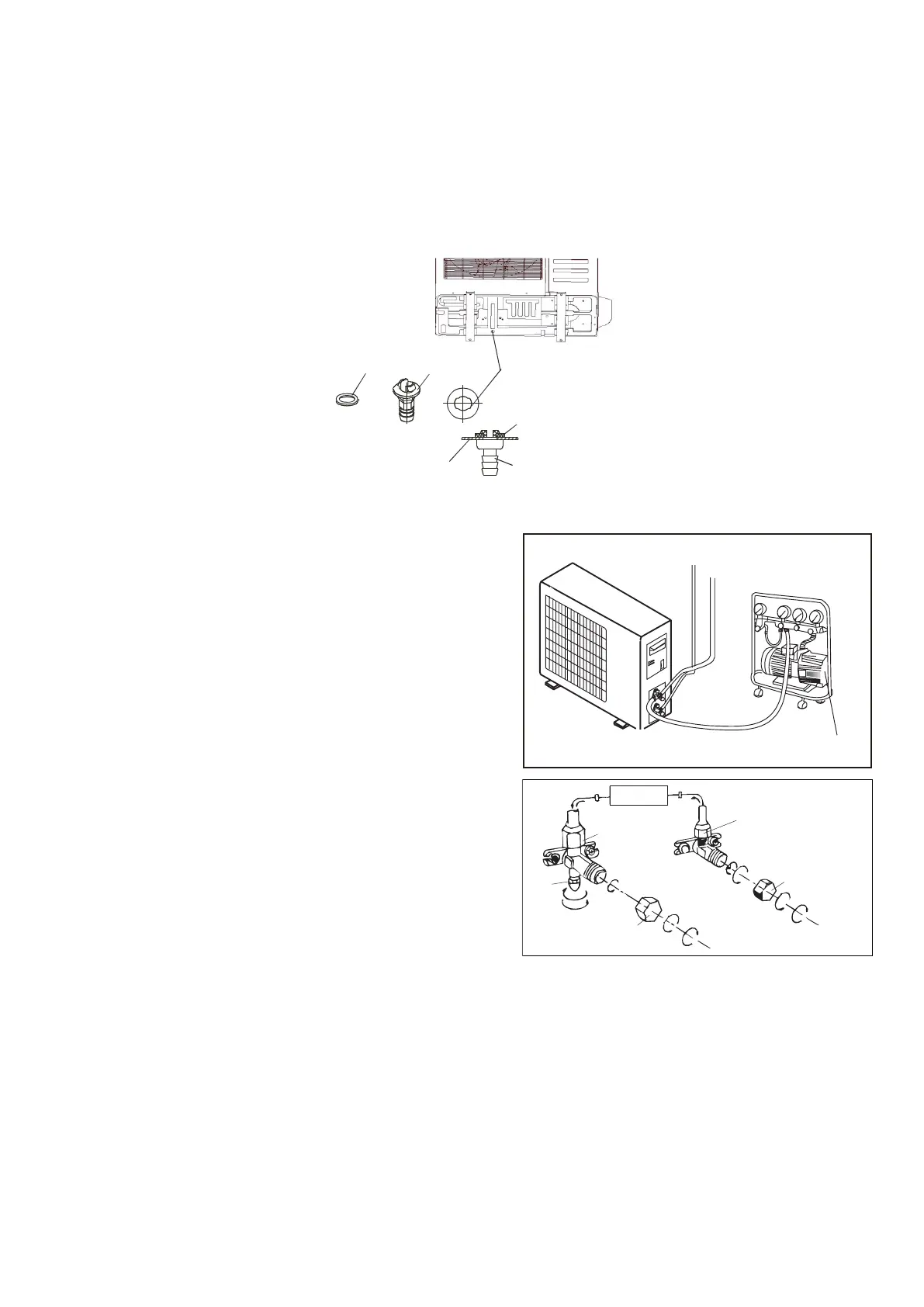

10.9 Installation of the drain joint and the condensate drain hose

Fit the seal into the drain joint, then insert the drain joint into the base pan hole of outdoor, rotate 90 to securely

assemble them. Connect the drain joint with an extension drain hose (Locally purchased), in case of the condensate

draining off the outdoor unit during the heating mode.

Seal

The base pan hole

of outdoor unit

Drain joint

Seal

The base pan

of outdoor unit

Drain

joint

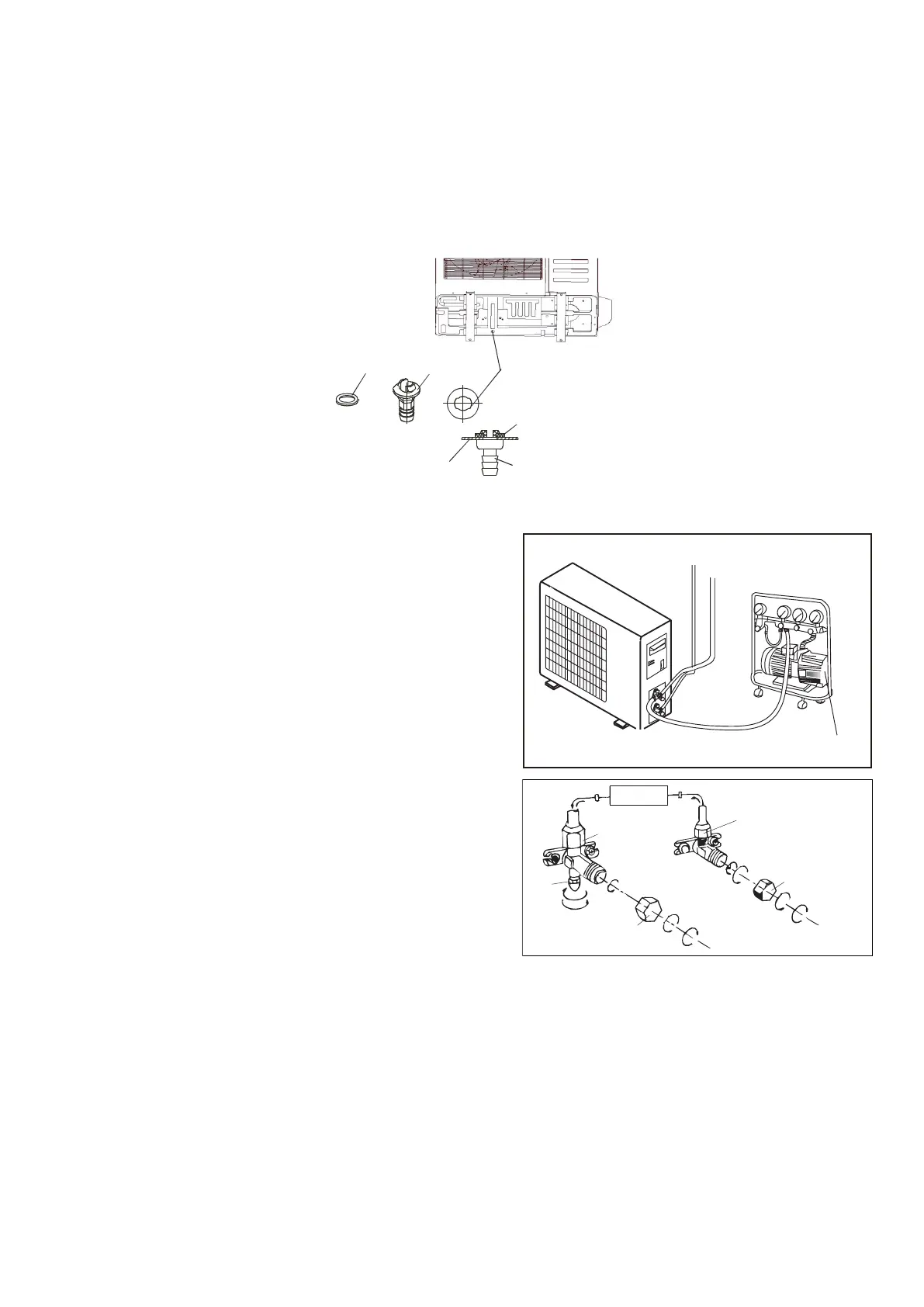

10.10 Vacuum pump

Humid air left inside the refrigerant circuit can cause

compressor malfunction. After having connected the indoor

and outdoor units, bleed the air and humidity from the

refrigerant circuit using a vacuum pump.

1)

Unscrew and remove the caps from the 2-way and 3-way

valves.

2)

Unscrew and remove the cap from the service valve.

3)

Connect the vacuum pump hose to the service valve.

4)

Operate the vacuum pump for 10-

absolute vacuum of 10 mm Hg has been reached.

5)

With the vacuum pump still in operation, close the low-

pressure knob on the vacuum pump coupling.

vacuum pump.

6)

Open the 2-way valve by 1/4 turn and then close it after 10

seconds. Check all the joints for leaks using liquid soap or an

electronic leak device.

7)

Turn the body of the 2-way and 3-way valves. Disconnect

the vacuum pump hose.

8)

Replace and tighten all the caps on the valves (see

paragraph 10.7 for tightening torque).

INDOOR

UNIT

Connect to the

indoor unit

Refrigerant fluid di

rection of fiow

3-way valve

2-way valve

inlet

(2)T

urn

(8) Secure

(7)Turn to open fully

(2)

Turn

(8) Secure

(6) Openby 1/4 turn

(7)

Turn to open fully

(2)Turn

(8) Secure

V

alve cap

Valve cap

Service

27

Loading...

Loading...