CAUTION!

To prevent personal injury:

• Always disconnect the plug from the power source when

making any adjustments.

• The adjustment must be correct. If it is not, kickback could

result in a serious injury and inability to make accurate cuts.

3332

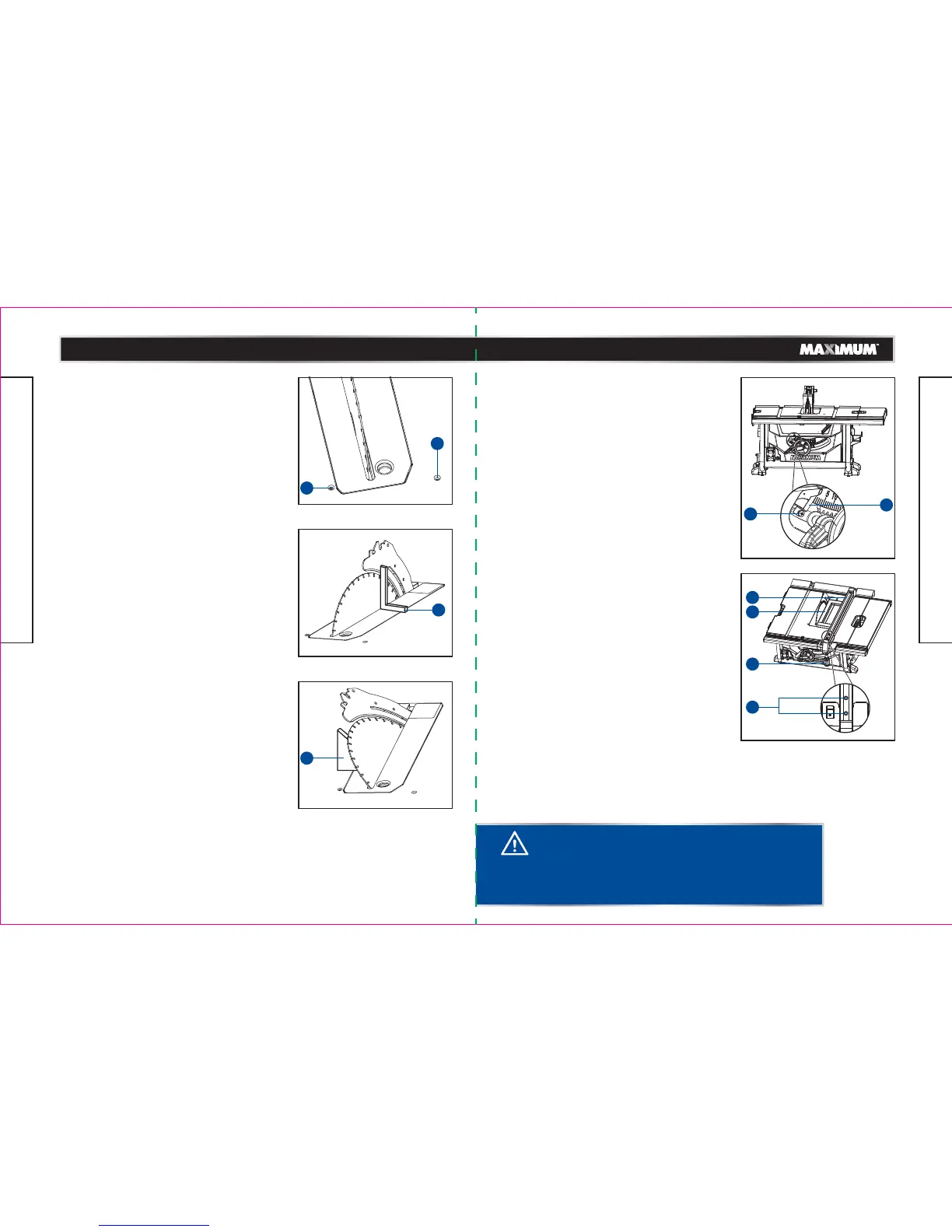

ADJUSTING THE BEVEL STOPS (Fig. 25-27)

This saw has positive stops that will quickly position

the saw blade at 90° or 45° to the table.

The angle settings of the saw have been set at the

factory and, unless damaged in shipping, should not

require setting during assembly. After extensive use,

it may need to be checked. Make adjustments only if

necessary.

• Unplug the saw.

• Remove the anti-kickback pawls assembly and

blade guard assembly.

• Raise the blade to the maximum height by turning

the height-adjusting knob clockwise.

• Using a framing square (1), set the blade to exactly

90°.

• If the blade stops bevelling before it gets to 90°,

loosen the 90°-stop set screw (2) (located at the

left of the table insert), and then adjust it to 90°.

• With the blade set at 90°, slowly turn the 90°-stop

set screw (2) until you feel resistance. Bevel the

blade away from 90° a little, and then back to the

stop.

• Re-measure the angle and repeat the stop

adjustment as necessary until the blade stops at

90°.

• Set the 45° stop in the same way. The 45°-stop set

screw (3) is located at the right of table insert. Use

the triangle square (4).

• Replace the anti-kickback pawls assembly and

blade guard assembly.

• Make a test cut.

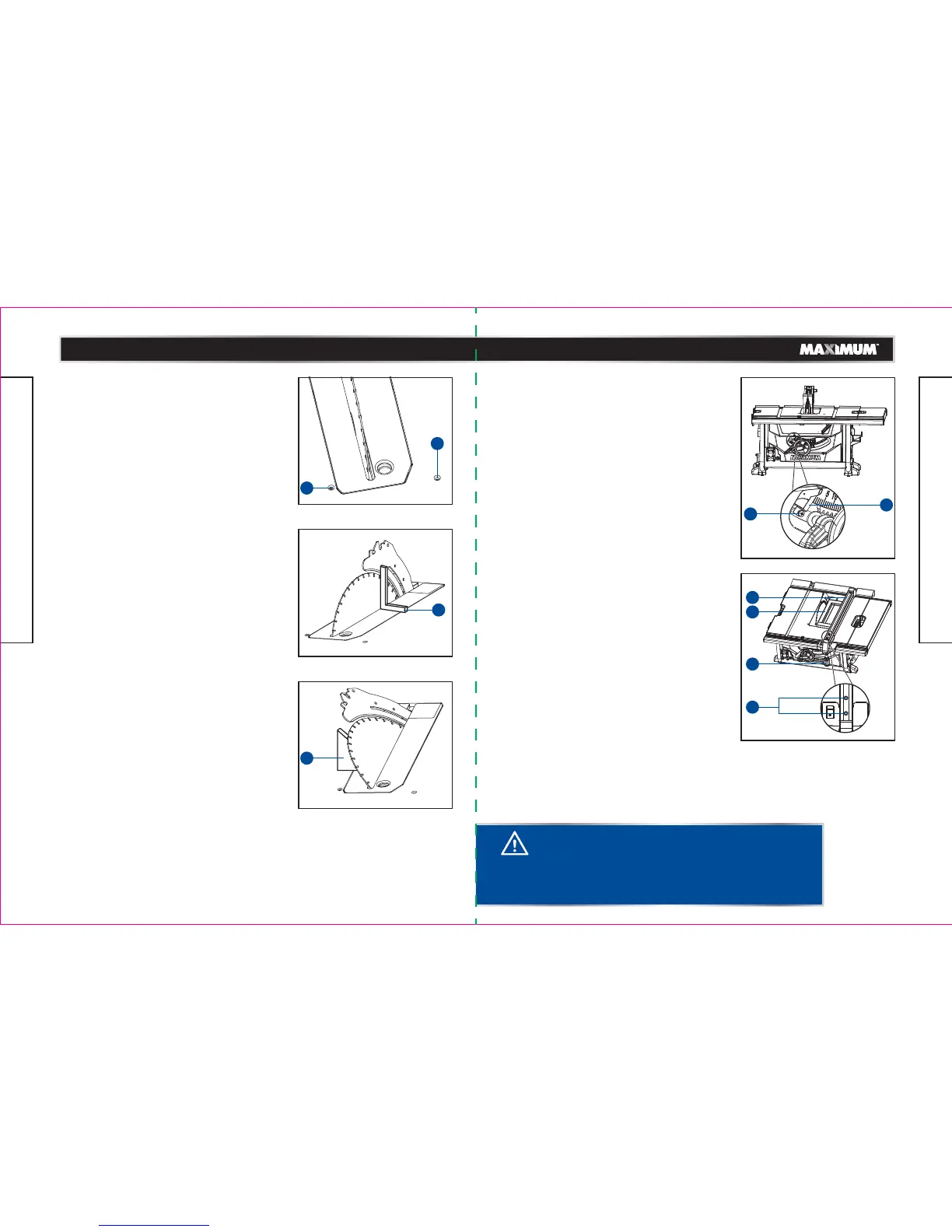

ADJUSTING THE BEVEL INDICATOR (Fig. 28)

If the bevel indicator (1) is not at 0° when the saw

blade is at 90°, adjust the indicator (1) by loosening

the cross screw (2) with a star-head screwdriver and

setting it to 0° on the bevel scale.

Retighten the cross screw (2).

Make sure that you make a trial cut on a scrap

piece of wood before making critical cuts. Measure

for exactness.

CHECKING THE ALIGNMENT OF THE RIP

FENCE TO THE BLADE (Fig. 29)

• Unplug the saw.

• Remove the blade guard assembly and anti-kickback

pawls assembly.

• Raise the locking handle (1) to allow the rip

fence (2) to be moved.

• Place the framing square (3) beside the blade, and

move the rip fence up to the square. Note the

measurement on the rip scale.

• Move the fence back and rotate the framing square

(3) 180° to check the other side.

• If the two measurements are not the same, loosen

the two socket head bolts (4) on the rip fence and

then align it.

• Retighten the two socket head bolts (4).

• Replace the blade guard assembly and anti-kickback

pawls assembly.

• Make two or three test cuts using scrap wood. If the

cuts are not true, repeat the process.

model no. 055-6766-2 | contact us 1-888-670-6682

ASSEMBLY

model no. 055-6766-2 | contact us 1-888-670-6682

ASSEMBLY

Fig. 28

Fig. 29

Fig. 25

Fig. 26

Fig. 27

2

3

1

4

1

4

2

1

2

3

Loading...

Loading...