11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

22

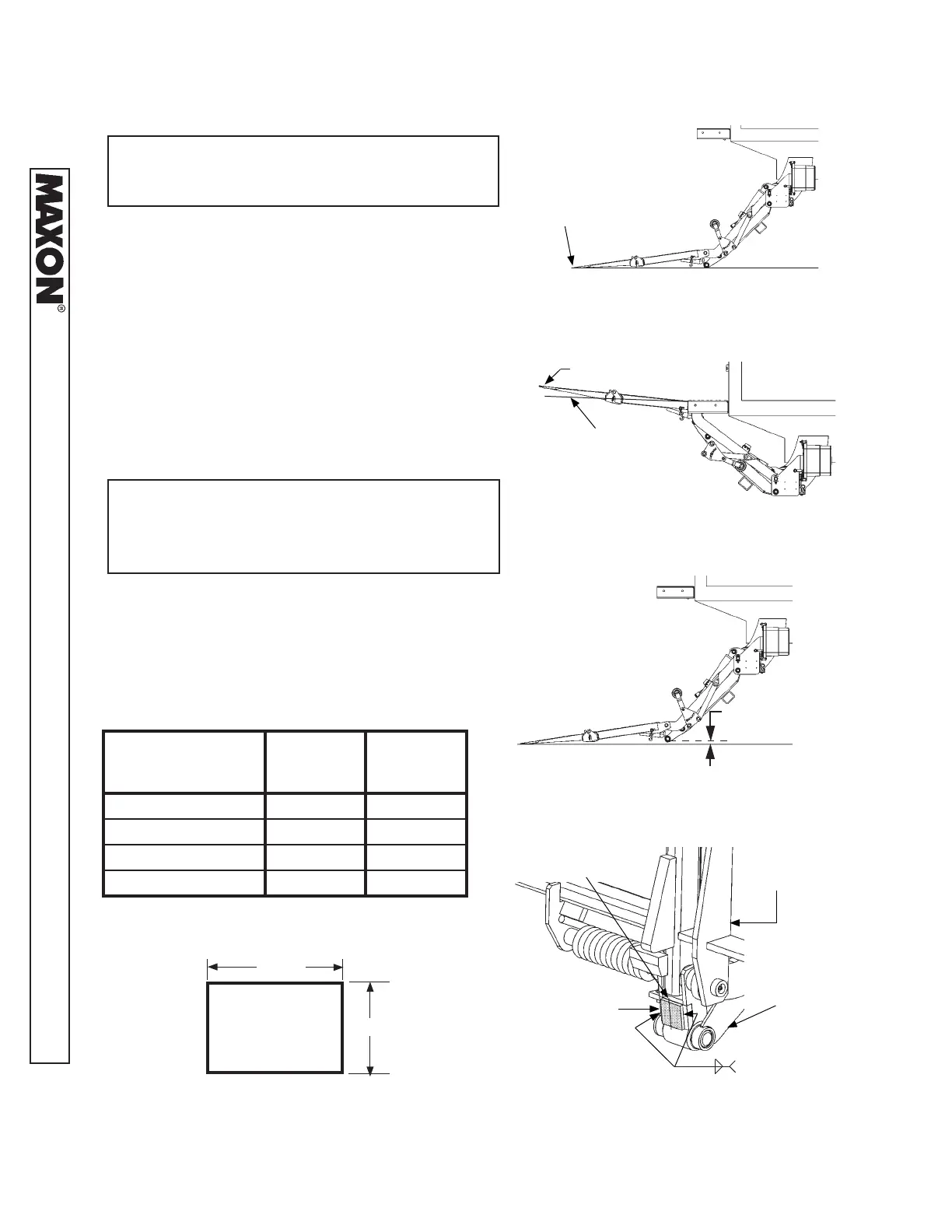

NOTE: Before doing the following procedure,

make sure vehicle is parked

on level ground.

PLATFORM & SHACKLES

TOUCH GROUND

FIG. 22-1

PLATFORM EDGE ABOVE

BED LEVEL

FIG. 22-2

1. Make sure platform is at ground level. Unfold

the platform and fl ipover. As the platform fi rst

touches the ground, shackles and tip of fl ipover

must touch the ground at the same time (FIG.

22-1). If shackles and tip of fl ipover touch the

ground at the same time, RAISE platform to bed

height. Tip of fl ipover should be above bed level

(FIG. 22-2). If indications are correct in both

cases (FIGS. 22-1 & 22-2), Liftgate is installed

correctly and no adjustment is needed. If indica-

tions are incorrect, continue with instruction 2.

TABLE 22-1

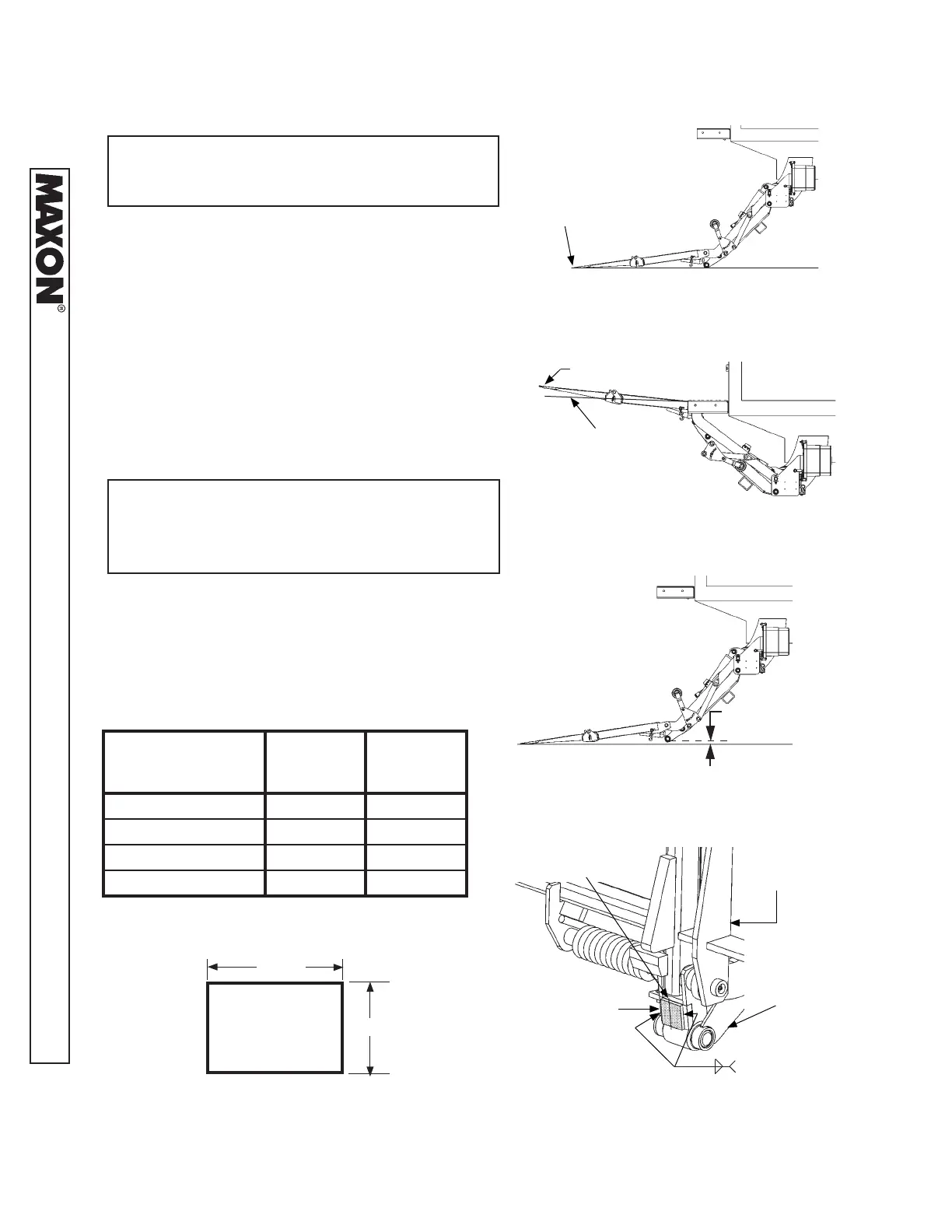

2. Make sure platform is still at ground level. If

the shackle is not touching the ground, mea-

sure and compare distance “A” (FIG. 22-3)

with TABLE 22-1 to determine the correct

shim. Make shims as needed (FIG. 22-5).

Weld shim as shown in FIG. 22-4.

NOTE: If tip of fl ipover touches fi rst (FIG.

22-3), do instruction 2. If the shackle

touches fi rst (FIG. 21-1), skip instruc-

tion 2 and do 3.

RAISE TIP OF

FLIPOVER

THIS DISTANCE “A”

REQUIRED

SHIM

THICKNESS

WELD SIZE

“W”

7/8” 1/16” 1/16”

2” 1/8” 1/8”

3” 3/16” 3/16”

3-15/16” 1/4” 1/4”

SHACKLES DO NOT TOUCH

GROUND

FIG. 22-3

WELDING SHIMS (CURBSIDE SHOWN)

FIG. 22-4

TIP OF

FLIPOVER

SHIM MADE FROM STEEL FLAT

FIG. 22-5

PERIODIC MAINTENANCE

PLATFORM ADJUSTMENT

2-1/4”

1-1/2”

TIP OF FLIPOVER

LEVEL LINE

“A”

(TABLE 22-1)

CENTERED

(TOP EDGES FLUSH)

PLATFORM

SHIM

(TABLE 22-1)

2 PLACES

“W”

(TABLE 22-1)

SHACKLE

(REF)

“W”

Loading...

Loading...