50 PROGRAMMING MANUAL 516532 B PUBLICATION DATE 1 JUN 2007.DOC

6. Check if the connectors on both sides of the

communication cable are still connected

Connect the connectors on the electronic timer board

and the inverter.

7. Check if the wiring is still continue Repair the wiring

8. Check if the output relays that activates the

safety inverter contactor is functional

If the relay is broken, replace the wash computer

DIAGNOSTIC CODE D12 : ALARM FREQUENCY INVERTER

Diagnostic Code D12 occurs when the frequency inverter goes into alarm. Except for the THT and the OV3

fault where the timer software will reset the inverter automatically (only 1x). The active process will be

interrupted immediately.

DIAGNOSE(ERR30):

1. Check if the correct machine type is

selected in the Configuration Menu.

If the wrong machine type is selected, enter the right

machine type

2. Check if the correct inverter parameters

have been implemented.

Load the correct Inverter parameters.

3. Check the frequency inverter error list to

know what happened.(See manual inverter)

If the fault is persistent, contact the manufacturer

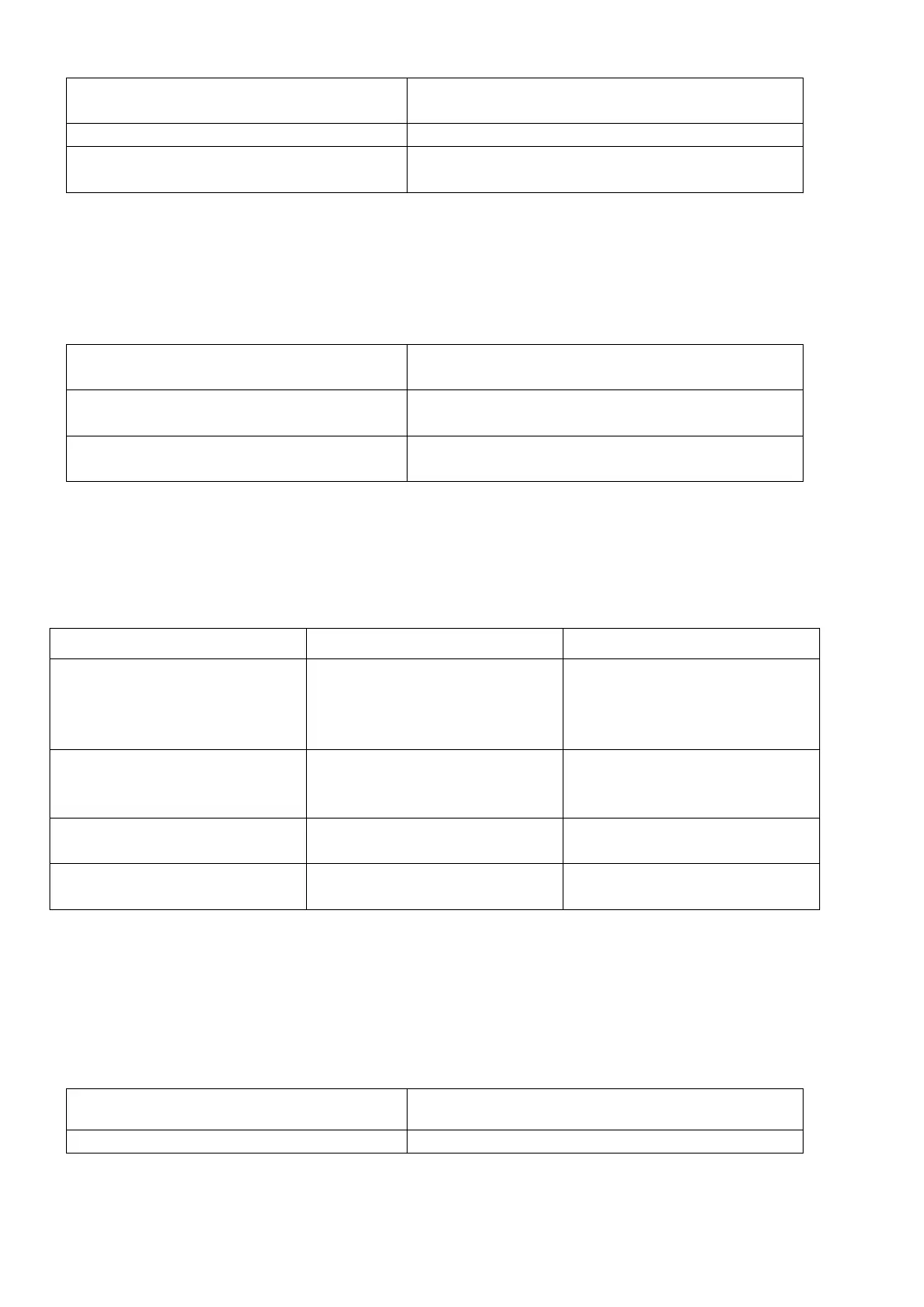

DIAGNOSTIC CODE D11 – D12 : PWM MOTOR DRIVE ERRORS AND PROBLEMS

D11 (E63, E64, E65) Drum doesn’t turn (no reset drive)

D12 (E66) Extended Speed (no reset drive)

D12 (E67) Continue Spin (no reset drive)

Problem Cause Solving the problem

The motor is spinning at 150 rpm * the belt is broken (when the belt

is broken, the load is so small

that the motor starts spinning at

150 RPM

* Change the motor belt.

The motor is shaking * bad contact in motor or

communication cable

* Check wiring and pin

connectivity and repair the

problem

The drum is not able to spin at it’s

max speed

* 1 phase is missing * Verify if the connector of motor

supply is well connected

The belt is slipping * check if the belt is wet * Make sure that no water gets on

the belt

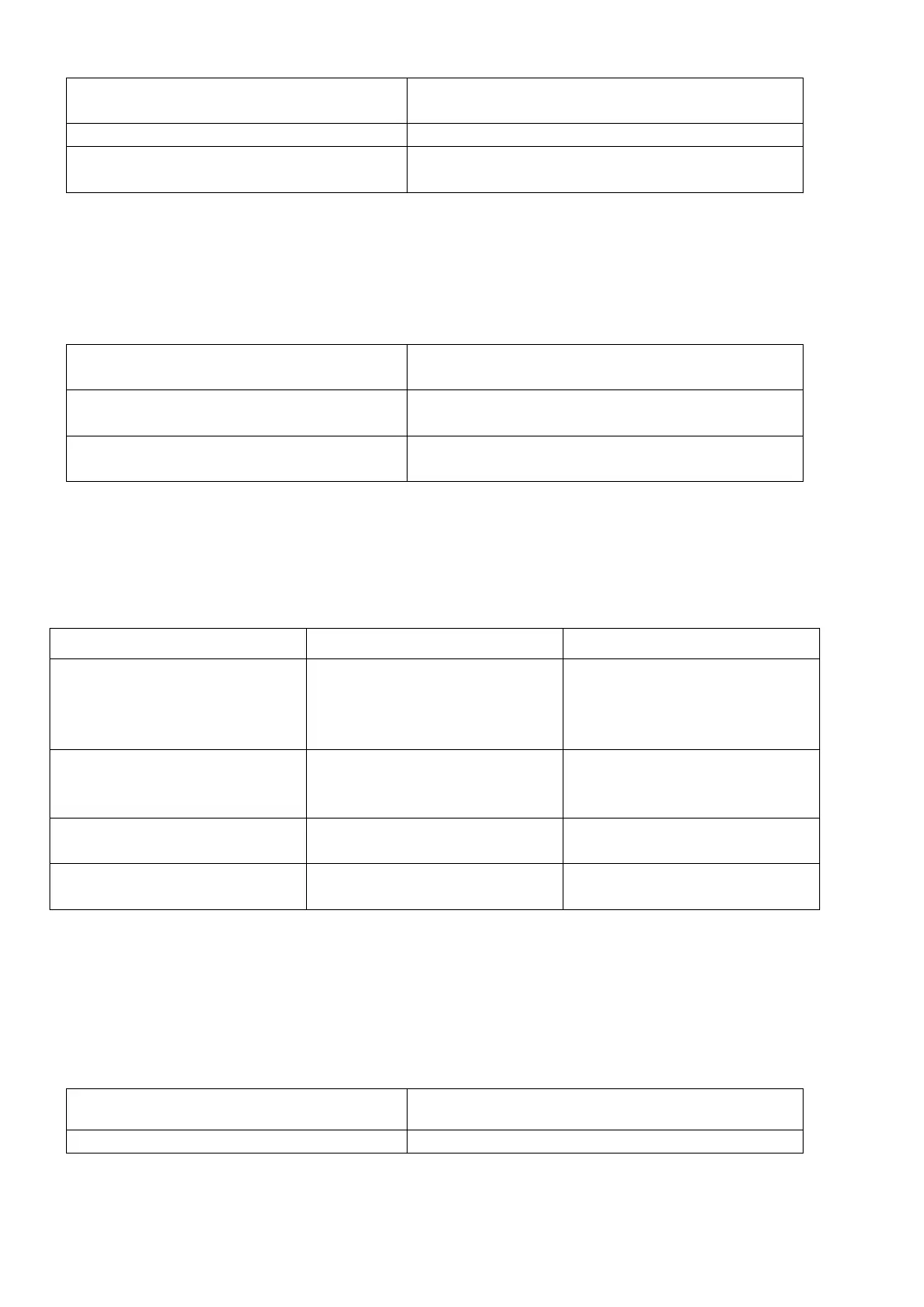

DIAGNOSTIC CODE D13 : COIN BLOCKING 2

When the input for coin drop 2 is blocked for more then 15 seconds, diagnostic D13 will be displayed.

When the problem disappears, the Diagnostic message will be cleared automatically.

Most likely the coinbox will get filled up completely with coins until they interrupt the infrared signal of the coin

sensor. After removing these coins the coinsystem will work again in a normal way.

DIAGNOSE (ERR17):

1. Check the well functioning of coin drop 1 If the coin drop micro contract or optocoupler is not

functioning 100% : replace the coin drop

2. Check the continuity of the wiring If the wiring is not continuous: repair the wiring

Loading...

Loading...