ENGINE

3.

b) The bearing must

be

replac-

ed if flaking is evident

over

one-half of its total

area or

if

the oil

clearances are

in-

correct.

(2)

Calculate the oil clearance

by

the following formula:

Oil

clearance

A

= (Min.

inside

dia.)

-

(Max.

journal

dia.)

Oil clearance B

=

(Max.

inside

dia.

-

(Min.

journal

dia.)

The

allowable

range

of

ances

is

0.07-0.10

mm.

Note:

There

is

an oversize

bearing available,

parl

num-

ber 1058 78

135, if

the stan-

dard size will

not

give

the

pro-

per

clearances.

Bearing

replacement.

(1)

Bearing removal.

a) Drill out the locking screw

withaTmmdrill.

b)

Use

the

special

tool, 49

0813 240,

to

press

out

the

bearing.

Notes:

a) Before

pressing

out the

bearing,

remove the

adap-

tor ring.

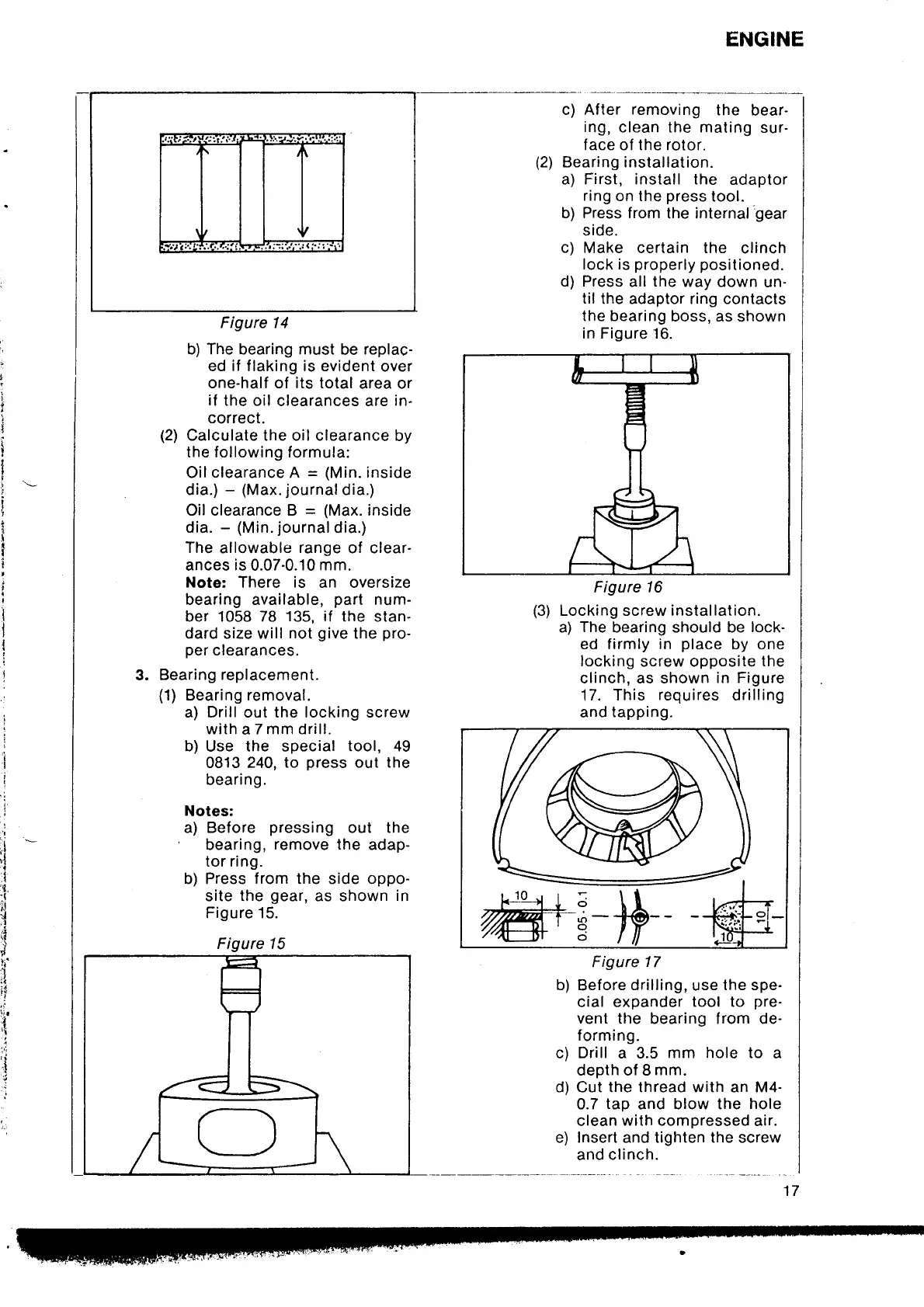

b) Press from the side oppo-

site the

gear,

as shown

in

Figure 15.

Figure 15

c) After

removing

the

bear-

ing,

clean the mating

sur-

face

of

the rotor.

(2)

Bearing installation.

a) First, install the

adaptor

ring

on the

press

tool.

b) Press from

the

internal'gear

side.

c)

Make certain the

clinch

lock is

properly positioned.

d) Press

all

the

way down

un-

til

the adaptor ring contacts

the bearing

boss, as

shown

in Figure 16.

Figure 16

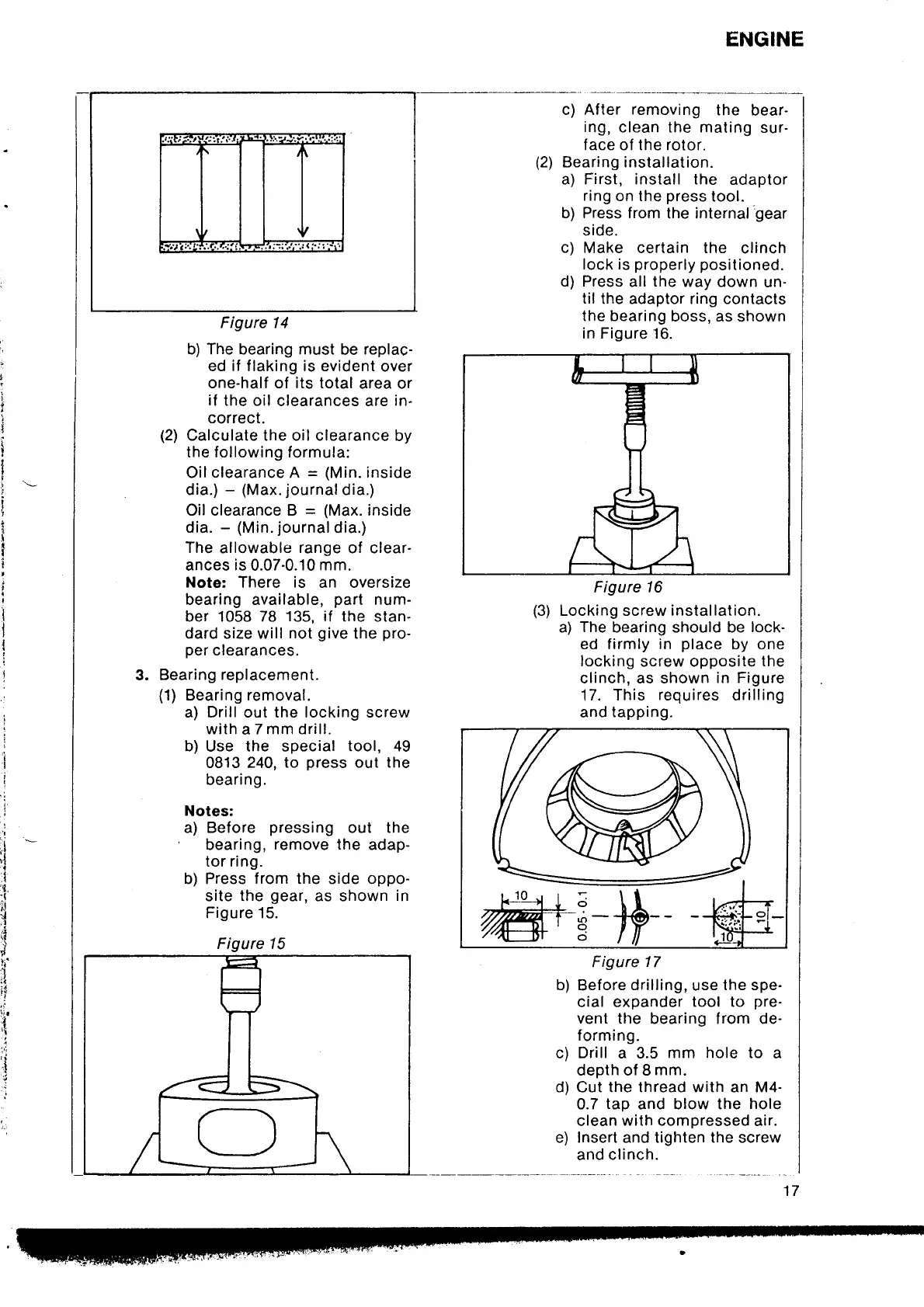

(3)

Locking screw installation.

a)

The

bearing should be

lock-

ed firmly in

place

by one

locking

screw opposite

the

clinch, as shown

in Figure

17. This

requires

drilling

and

tapping.

Figure 17

b)

Before

drilling,

use

the spe-

cial expander

tool

to

pre-

vent

the bearing from de-

forming.

c) Drill a 3.5

mm hole to

a

depth of 8

mm.

d) Cut the thread with an M4-

0.7

tap

and blow the

hole

clean

with compressed

air.

e) Insert and tighten the screw

and

clinch.

i

J

l;

.-

il

,t

:l

.{

,I

-t

l!

d

.!

.t

I

,.i

i1

i"{

,i

.t

ti

iii

,i

,l

t

'i

17

Figure l4

Loading...

Loading...