ENGINE

(5)

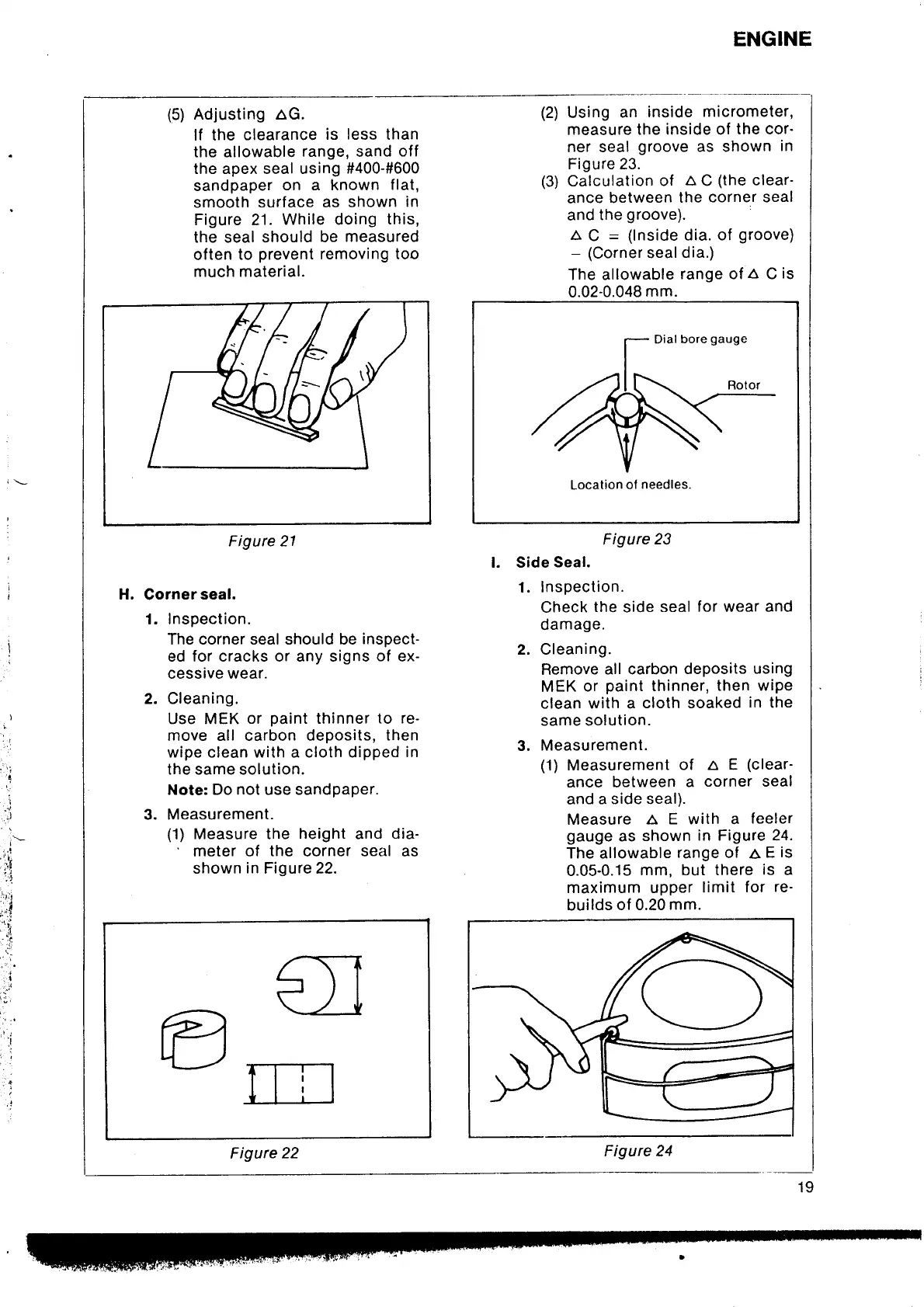

Adjusting aG.

lf the

clearance

is

less

than

the allowable

range, sand

off

the apex seal using

#400-#600

sandpaper

on a known

flat,

smooth

surface as

shown

in

Figure 21.

While doing

this,

the seal should

be

measured

often

to

prevent

removing too

much material.

H.

Corner

seal.

1. Inspection.

The corner seal should be

inspect-

ed for cracks or any signs

of

ex-

cessive wear.

2. Cleaning.

Use MEK

or

paint

thinner

to re-

move all carbon deposits,

then

wipe clean with a cloth dipped

in

the same solution.

Note: Do not use sandpaper.

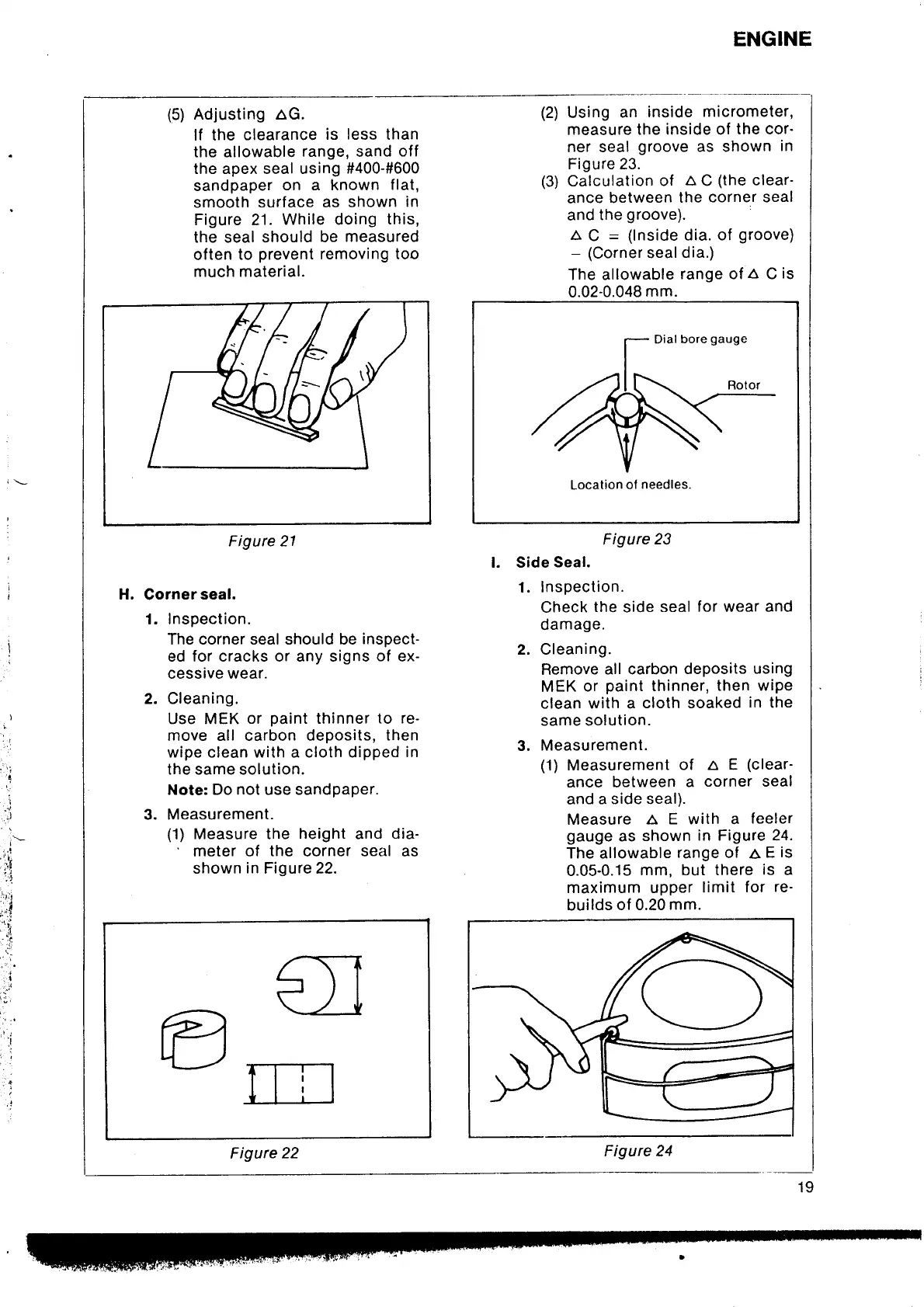

3. Measurement.

(1)

Measure the

height

and

dia-

'

meter of the corner seal as

shown

in

Figure 22.

Using

an

inside

micrometer,

measure

the inside of

the cor-

ner seal

groove

as shown

in

Figure 23.

Calculation

of

A

C

(the

clear-

ance between

the

corner seal

and

the

groove).

A

C

=

(lnside

dia. of

groove)

-

(Corner

seal

dia.)

The allowable

range of

a

C

is

0.02-0.048

mm.

Dial

bore

gauge

Location

of

needles.

Figure

23

l. Side

Seal.

1. Inspection.

Check

the

side

seal

for wear and

damage.

2. Cleaning.

Remove

all carbon

deposits

using

MEK

or

paint

thinner,

then wiPe

clean with a

cloth soaked

in

the

same solution.

3. Measurement.

(1)

Measurement

of a E

(clear-

ance between

a

corner seal

and

a side seal).

Measure

aEwithafeeler

gauge

as

shown

in Figure 24-

The allowable

range of

a

E

is

0.05-0.15

mm, but there

is

a

maximum upper

limit

for

re-

builds

of 0.20

mm.

(2\

(3)

i

.l

t

rll

,

:,1

tl

.'rii

'.

l

.rl

r;

".i:

1;l

't

-:i

,,

;

,i

t.;i

';;

'l

€I

P

\--

ill_]

Figure

22

Loading...

Loading...