Note: After attaching

the center

support bearing, check and

make

certain the driveshaft

is

straight

and true. lt

is recommended

to

check

for

driveshaft straightness

before

final welding on the brack-

ets. One

suggested

method to

check

for

straightness

is

to tie

weighted strings

to the transmis-

sion extension

housing, center

bearing and differential compan-

ion flange, then visually

note

the

alignment

from the rear; make

certain all

the

strings

hang from

the exact centers of

the

three

locations.

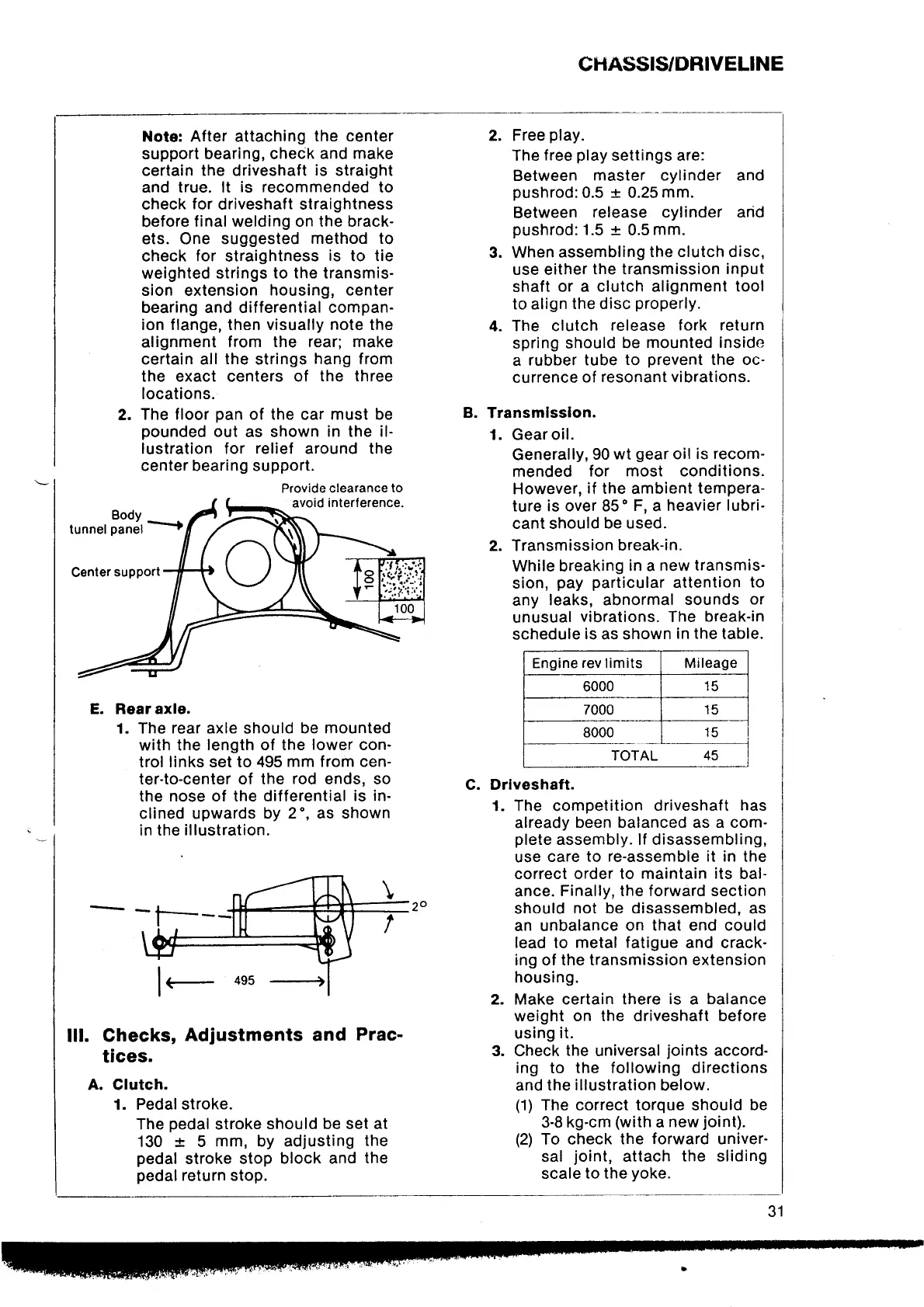

2.

The floor

pan

of the car must be

pounded

out

as shown

in the il-

lustration for

relief

around the

center bearing support.

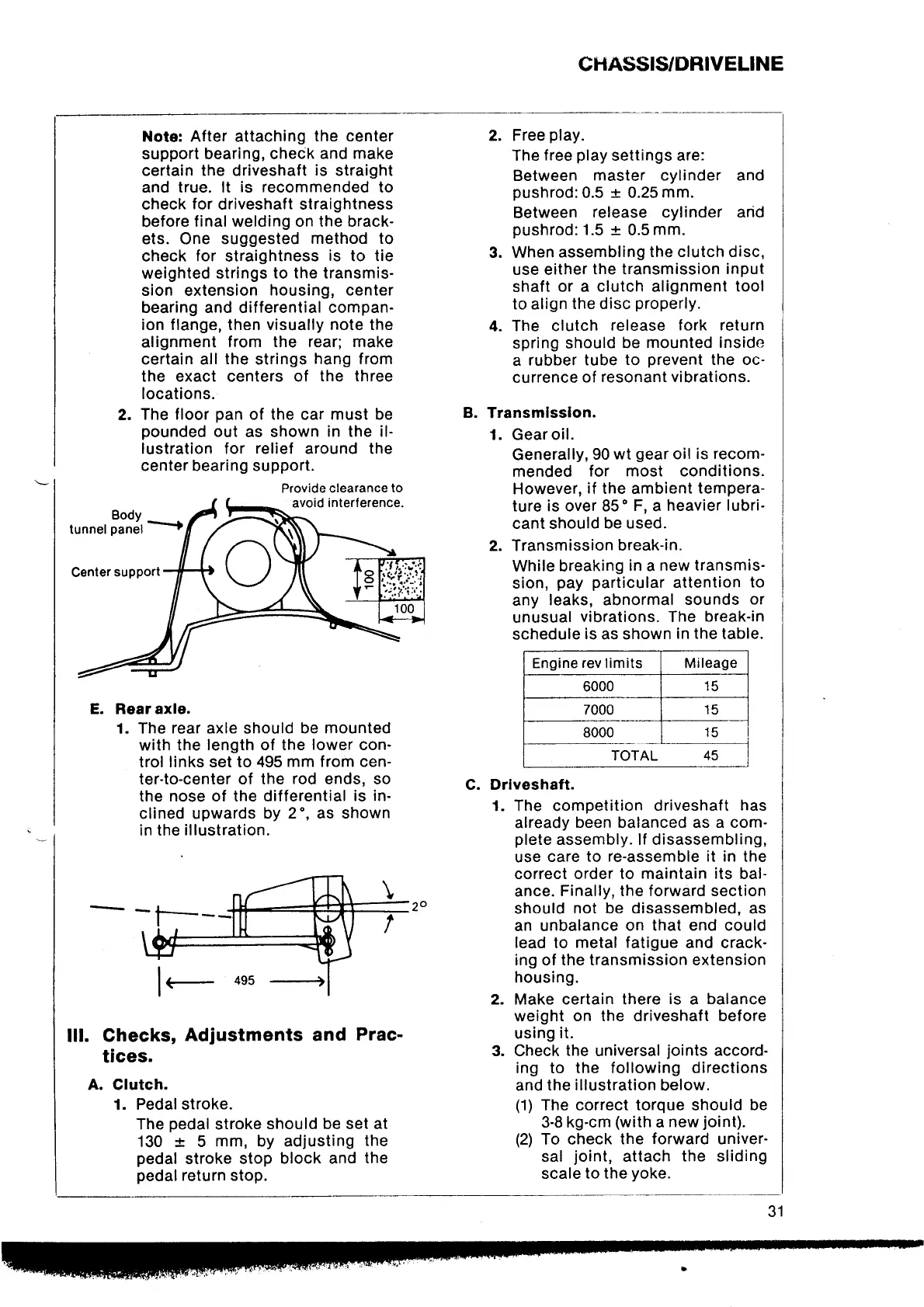

E. Rear axle.

1. The

rear

axle should

be mounted

with the

length of the

lower

con-

trol

links set to 495

mm from cen-

ter-to-center of the

rod

ends, so

the

nose of the differential

is in-

clined upwards by

2", as shown

in the

illustration.

lll.

Checks,

Adjustments and

Prac-

tices.

A. Clutch.

1. Pedal stroke.

The

pedal

stroke

should

be set at

130

'r

5

mm, by adjusting

the

pedal

stroke stop

block and

the

pedal

return stop.

CHASSIS/DRIVELINE

2.

Free

play.

The

free

play

settings are:

Between

master cylinder

pushrod:0.5

-r

0.25

mm.

Between

release

cylinder

pushrod:1.5

+

0.5mm.

When

assembling

the clutch disc,

use either

the transmission

input

shaft

or a clutch alignment

tool

to align

the disc

properly.

The clutch

release

fork return

spring

should

be

mounted inside

a

rubber tube

to

prevent

the oc-

currence

of

resonant vibrations.

B. Transmlsslon.

1. Gear oil.

Generally,90

wt

gear

oil is

recom-

mended

for most conditions.

However,

if

the ambient

tempera-

ture is over 85o

F,

a

heavier

lubri-

cant should

be used.

2. Transmission

break-in.

While breaking

in

a

new transmis-

sion,

pay particular

attention

to

any

leaks, abnormal

sounds

or

unusual

vibrations. The

break-in

schedule

is

as shown

in

the

table.

Engine

rev

limits Mileage

6000

15

7000

15

8000

15

TOTAL

45

C. Driveshaft.

The competition

driveshaft has

already

been

balanced

as a com-

plete

assembly. lf disassembling,

use

care

to re-assemble it in

the

correct order to maintain

its

bal-

ance.

Finally, the forward section

should

not be disassembled,

as

an unbalance

on that end could

lead

to

metal fatigue

and crack-

ing

of

the transmission extension

housing.

Make certain there

is

a

balance

weight on the driveshaft before

using

it.

Check

the

universal

joints

accord-

ing to the following

directions

and the

illustration

below.

(1)

The correct torque should be

3-B kg-cm

(with

a

new

joint).

(2)

To check

the forward univer-

sal

joint,

attach

the

sliding

scale to the

yoke.

arid

3.

4.

1.

2.

3.

Loading...

Loading...