11

洗涤剂罐盖

12

洗涤剂量调节旋钮

13

压力表

14

喷射压力调节旋钮

15

油箱盖

4.4 安全设备(装置)

TST -

总停止装置

本手册中描述的压力垫圈模型配备了一种防止机器在长期暂停使用时过热的装置。配有托塔尔停止装置的型号有一个额外的安全特

性,即在喷涂阶段结束时停止使用机器(喷雾枪关闭,没有按扳机);在这种情况下,机器将停止工作。要恢复使用,只需按下喷枪上

的扳机即可。

DSS - 降停系统装置

在小泄漏情况下,该系统会禁用总停系统

MAZZONI 压力表保护装置

本手册中描述的压力垫圈模型(W系列型号除外)配有压力表保护装置。这个装置是为了减少压力的磨损而设计的。 E规,允许使用机

器,即使它应该坏了。

在交付时,马佐尼压力垫圈提供的压力表运行,因此容易磨损。用户可以在任何时候通过禁用计量器来保护它,否则就应该关闭它。

如果它中断,它可以很快被禁用,如下所示,以便允许工作继续进行:

• 关掉机器。

• 检查电路中没有压力。

• 使用14毫米组合扳手将压力表顺时针旋转45°。

• 压力表现在已失效。

可以在任何时候重新启用压力表的操作,只需将它恢复到原来的位置,确保机器在执行时总是关闭。.

为了禁用该系统,请按以下步骤进行:

• 关掉机器。

• 检查电路中没有压力。

• 使用14毫米组合扳手,完全松开压力表。

• 用小螺丝刀拆下阀座和垫圈。

• 插入聚四氟乙烯颗粒(在压力垫圈小册子内提供-见第4.4 H章)。

• 用手在压力表上拧螺丝。

• 用14毫米组合扳手拧紧,至少顺时针转动压力表一圈。

• 检查使用期间是否有泄漏。

执行此操作后,压力表将永久工作,如果发生故障,在更换压力表之前,机器将无法使用。

WATER LEAK DEVICE

由于漏水(PH和W系列),机器在第六次重新启动后停止运行。

FUEL LEVEL Device

如果柴油不足,该装置将阻止锅炉运行,而MH系列则会使机器停止工作。

SDL - 安全洗涤剂液位装置

当水箱中的洗涤剂完成后,防止空气被吸入。

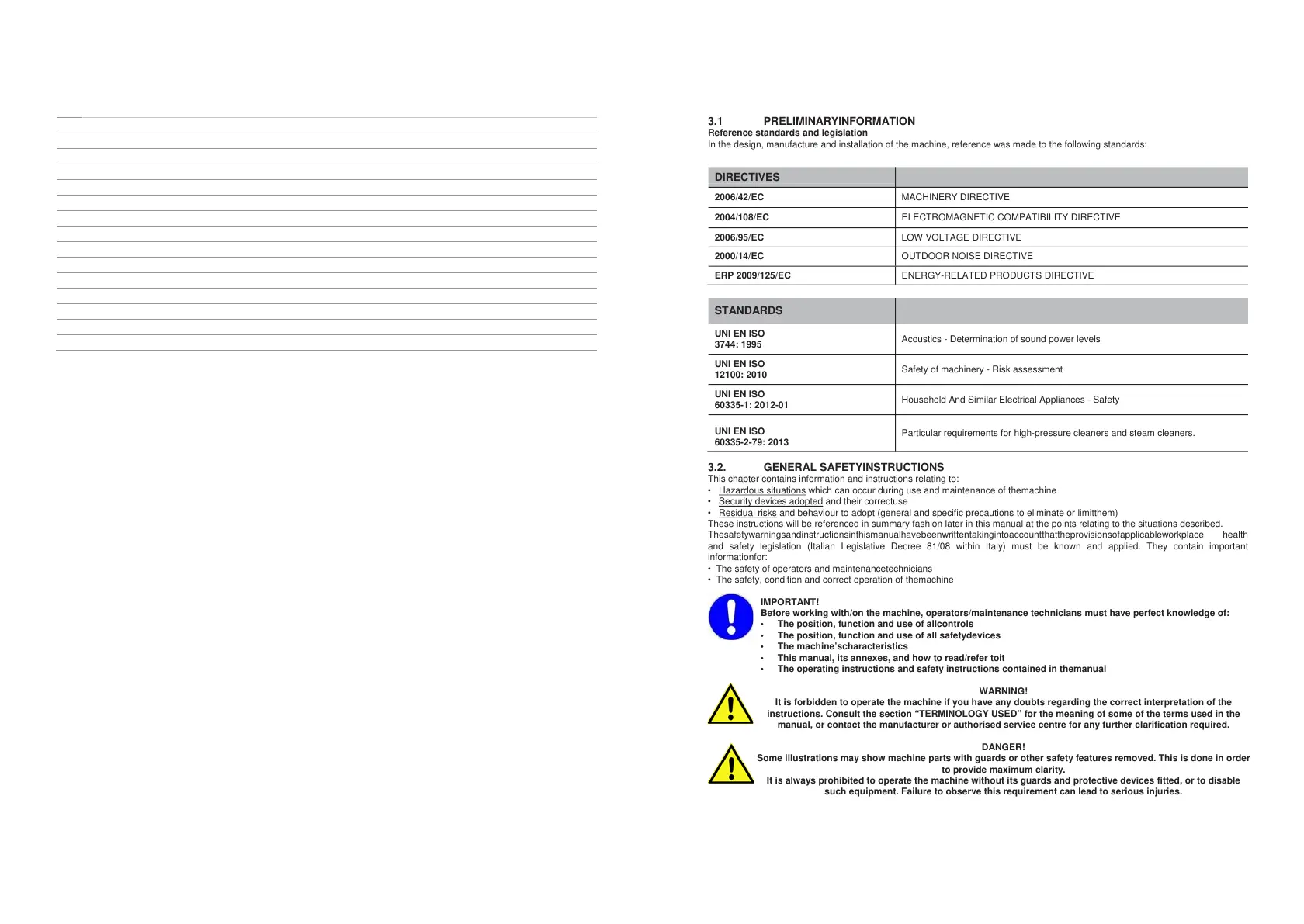

2006/42/EC MACHINERY DIRECTIVE

2004/108/EC ELECTROMAGNETIC COMPATIBILITY DIRECTIVE

2006/95/EC LOW VOLTAGE DIRECTIVE

2000/14/EC OUTDOOR NOISE DIRECTIVE

ERP 2009/125/EC ENERGY-RELATED PRODUCTS DIRECTIVE

STANDARDS

Particular requirements for high-pressure cleaners and steam cleaners.

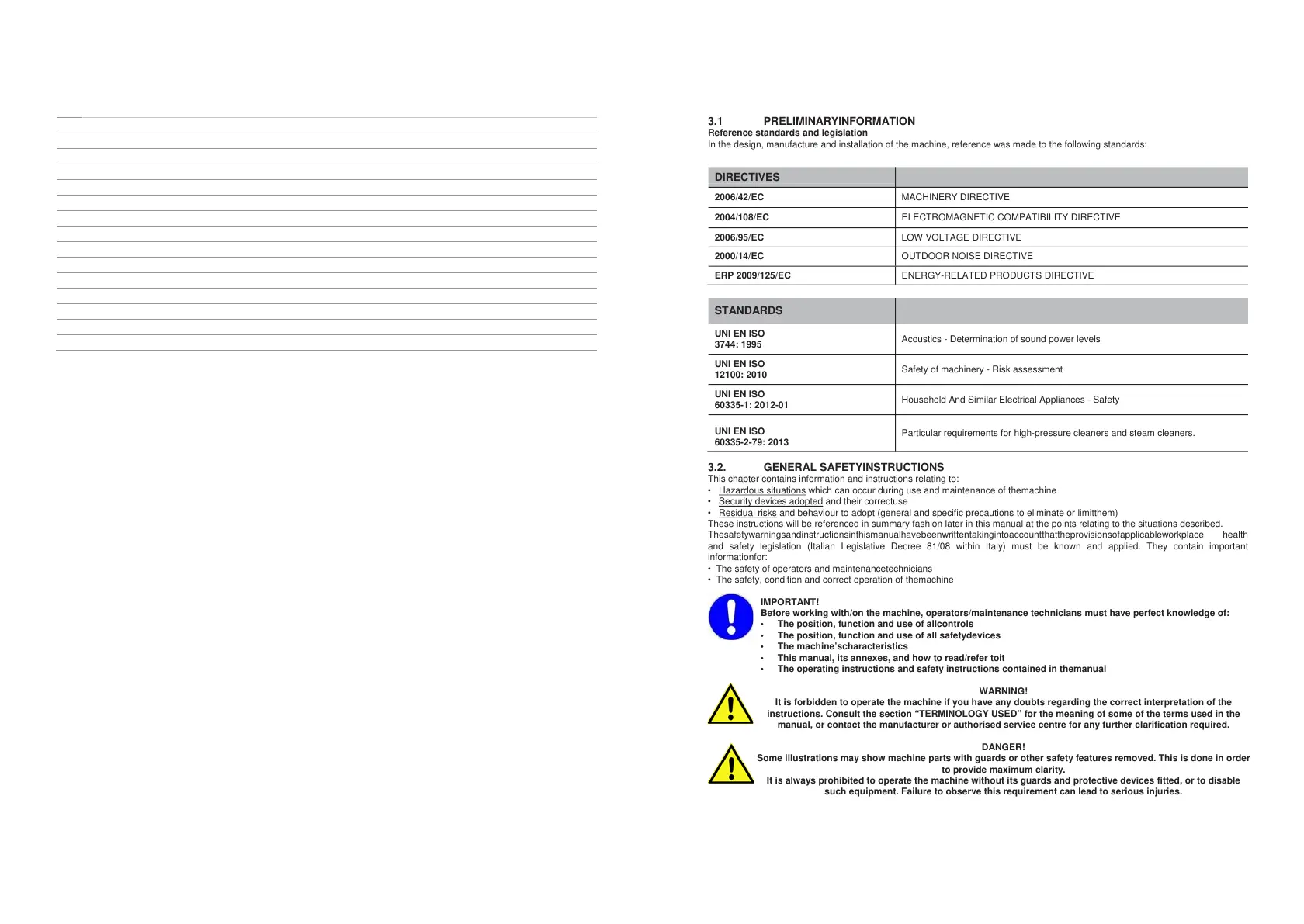

3.2. GENERAL SAFETYINSTRUCTIONS

This chapter contains information and instructions relating to:

• Hazardous situations which can occur during use and maintenance of themachine

• Security devices adopted and their correctuse

• Residual risks and behaviour to adopt (general and specific precautions to eliminate or limitthem)

These instructions will be referenced in summary fashion later in this manual at the points relating to the situations described.

Thesafetywarningsandinstructionsinthismanualhavebeenwrittentakingintoaccountthattheprovisionsofapplicableworkplace health

and safety legislation (Italian Legislative Decree 81/08 within Italy) must be known and applied. They contain important

informationfor:

• The safety of operators and maintenancetechnicians

• The safety, condition and correct operation of themachine

IMPORTANT!

Before working with/on the machine, operators/maintenance technicians must have perfect knowledge of:

• The position, function and use of allcontrols

• The position, function and use of all safetydevices

• The machine’scharacteristics

• This manual, its annexes, and how to read/refer toit

• The operating instructions and safety instructions contained in themanual

WARNING!

It is forbidden to operate the machine if you have any doubts regarding the correct interpretation of the

instructions. Consult the section “TERMINOLOGY USED” for the meaning of some of the terms used in the

manual, or contact the manufacturer or authorised service centre for any further clarification required.

DANGER!

Some illustrations may show machine parts with guards or other safety features removed. This is done in order

to provide maximum clarity.

It is always prohibited to operate the machine without its guards and protective devices fitted, or to disable

such equipment. Failure to observe this requirement can lead to serious injuries.

Loading...

Loading...