12

4. With the Tone Arm parallel to the record surface,

record platter and turntable base, tighten the set

screw, which was loosened in step 2. If not, repeat

steps 1, 2 and 3 until the Tone Arm is parallel.

Setting the Tracking Force Pressure

The MT2 is supplied with a Stylus Tracking Force

Gauge for checking and adjusting the Stylus Track-

ing Pressure. The Gauge uses the “Balance Scale”

methodology for measurement. Place the Gauge on

the record mat and perpendicular to the front of the

Tone Arm, with the Stylus Tip over graduation marks.

Set the Anti-Skate Adjustment to minimum (refer to

figure 32). Adjust the position of the Tone Arm Coun-

terweight to establish a tracking force pressure in the

middle of the recommend range from the Cartridge

manufacturer as a starting place. Refer to figures 28

thr u 31.

Note: Usually, adjusting the tracking force pressure

closer to the maximum setting recommend by

the Cartridge Manufacturer will produce better

sound with less record and stylus wear. Refer

to “Trackability Adjustments” for additional

information.

Anti-Skating Adjustment

The MT2 has adjustable Anti-Skating to equalize the

pressure on both sides of the record groove wall by

rotating the Anti-Skating Weight Up and Down the

threaded shaft, refer to figure 32.

For additional information about Tracking Force Pres-

sure and Anti-Skating refer to “Trackability Adjust-

ments”.

Installing a non-supplied Cartridge and Tone Arm Adjustments

Trackability Adjustments

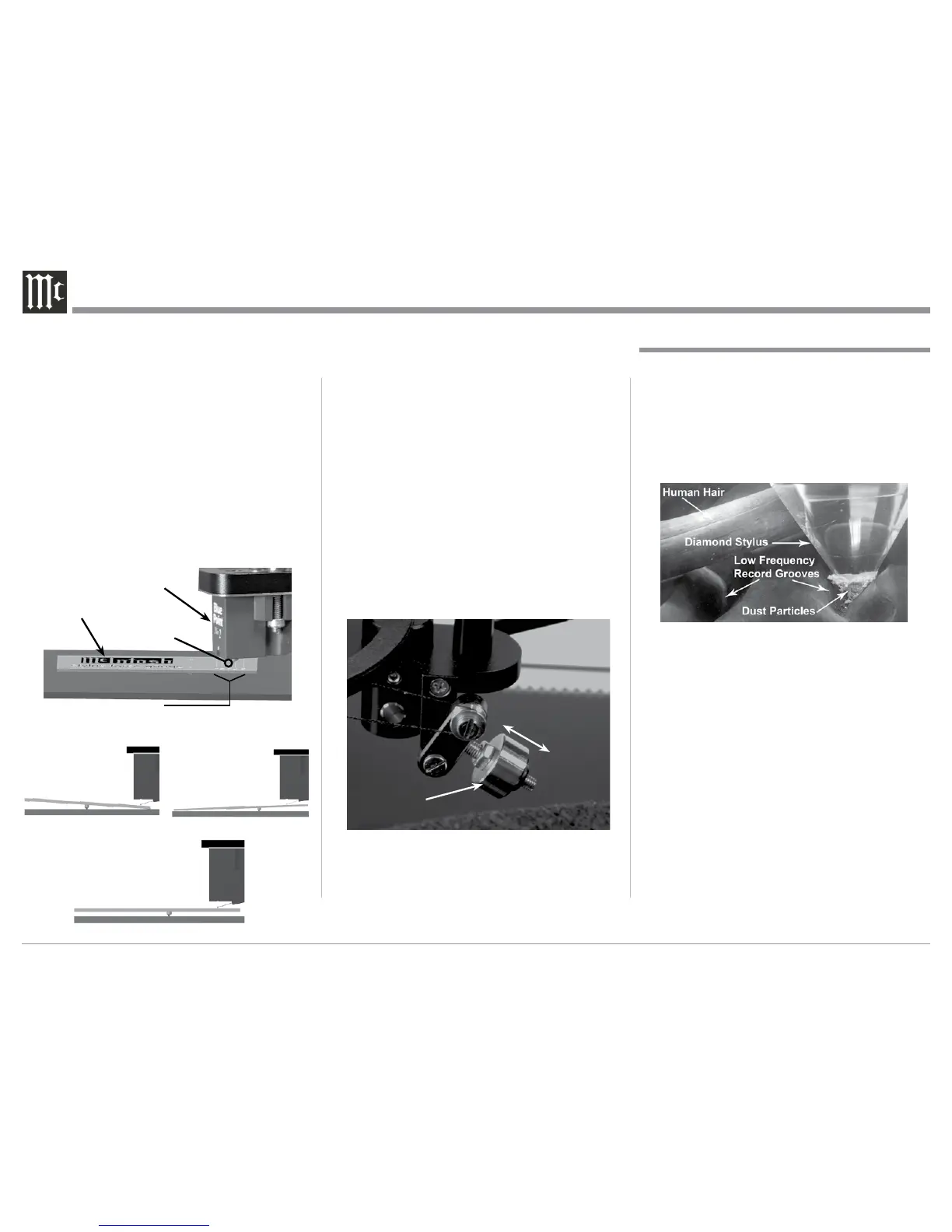

During playback of Phonograph Recordings, the stylus

assembly is subjected to all kinds of extreme operat-

ing conditions. One of those conditions is the forces

constantly trying to push the stylus up and out of the

grooved wall of the recording. Another condition is

the uneven side to side pressure applied to the stylus

as it tries to stay in contact with both sides of the

groove wall of the recording. Refer to figure 35.

The Anti-Skating Adjustment permits equalizing

for even side to side pressure. The correct amount of

Tracking Force Pressure and Anti-Skate Pressure var-

ies with the exact shape of the Stylus Tip and finally

the audio signal (both frequency and amplitude) con-

tained in the groove wall of the record.

To achieve good performance and the least amount

of Stylus Tip/Record Groove wear, use a Trackablity

Test Record. Both Tracking Force and Anti-Skate Ad-

justments are made as a result of listening to the test

record to reduce different forms of audible distortions.

Never exceed the manufacturers recommend Maxi-

mum Tracking Force Pressure Setting.

Your McIntosh Dealer, using Test Measurement

Equipment and Professional Test Recordings, can

achieve via adjustments, the best possible sound qual-

ity from your record collection and ensure the greatest

longevity.

Figure 35

Figure 28

Stylus

Force

Gauge

Stylus Tip

Cartridge

Stylus Pressure Scale

(Graduations are in grams)

Figure 29

Stylus Pressure

Set higher than

gauge marking

Figure 30

Stylus Pressure

Set lower than

gauge marking

Figu re 31

Stylus Pressure Set the

same as gauge marking

Figure 32

Antiskating

Weight

Antiskating

Adjustment

Maximum

Minimum

Loading...

Loading...