The auxiliary relay is designed to interface external equip-

ment with the Mark IV/AC board. The auxiliary relay has been

provided with the components necessary to protect from

electrical damage that may occur to the Mark IV/AC board

when using standard off-the-self relays. The auxiliary relay

Auxilliary Relay (P/N 03005073)

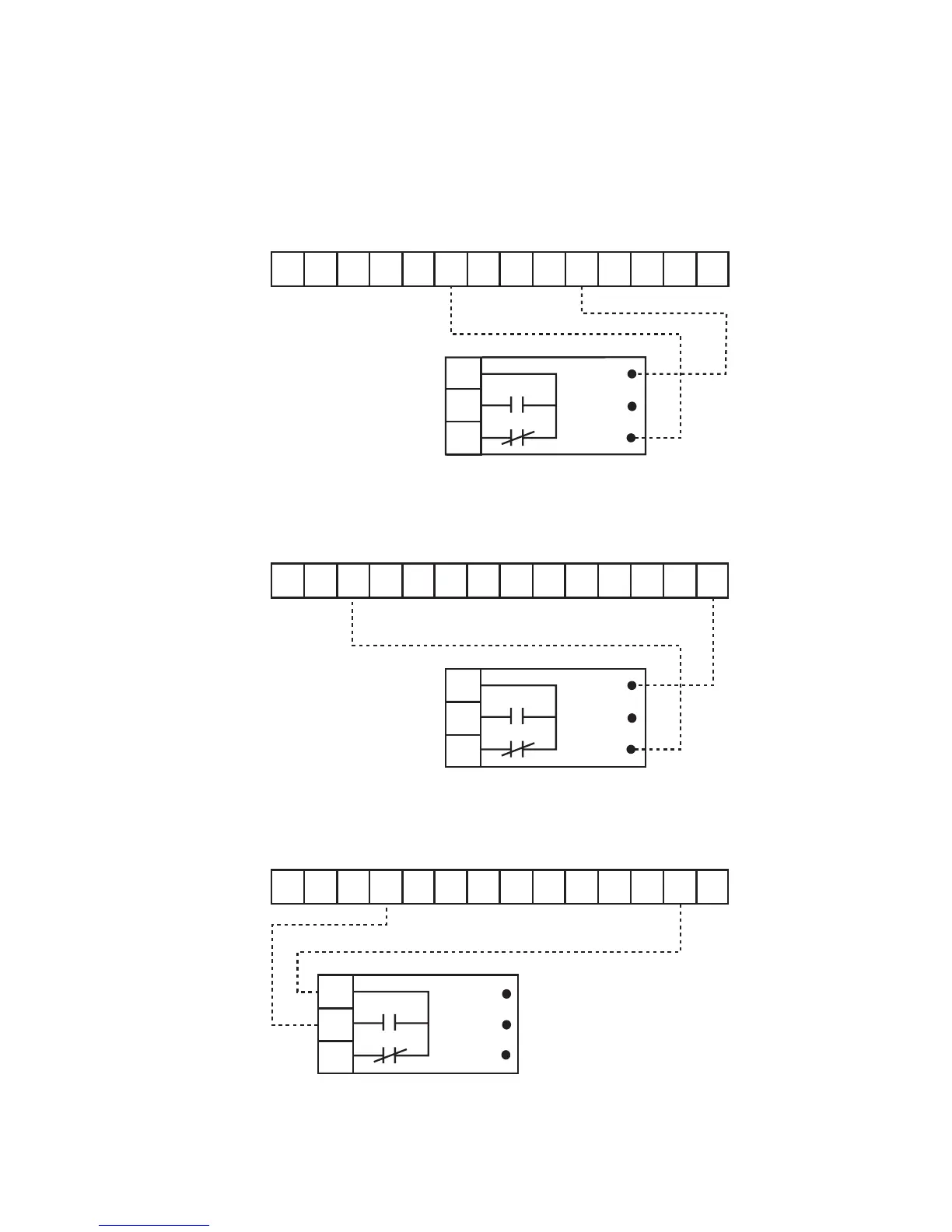

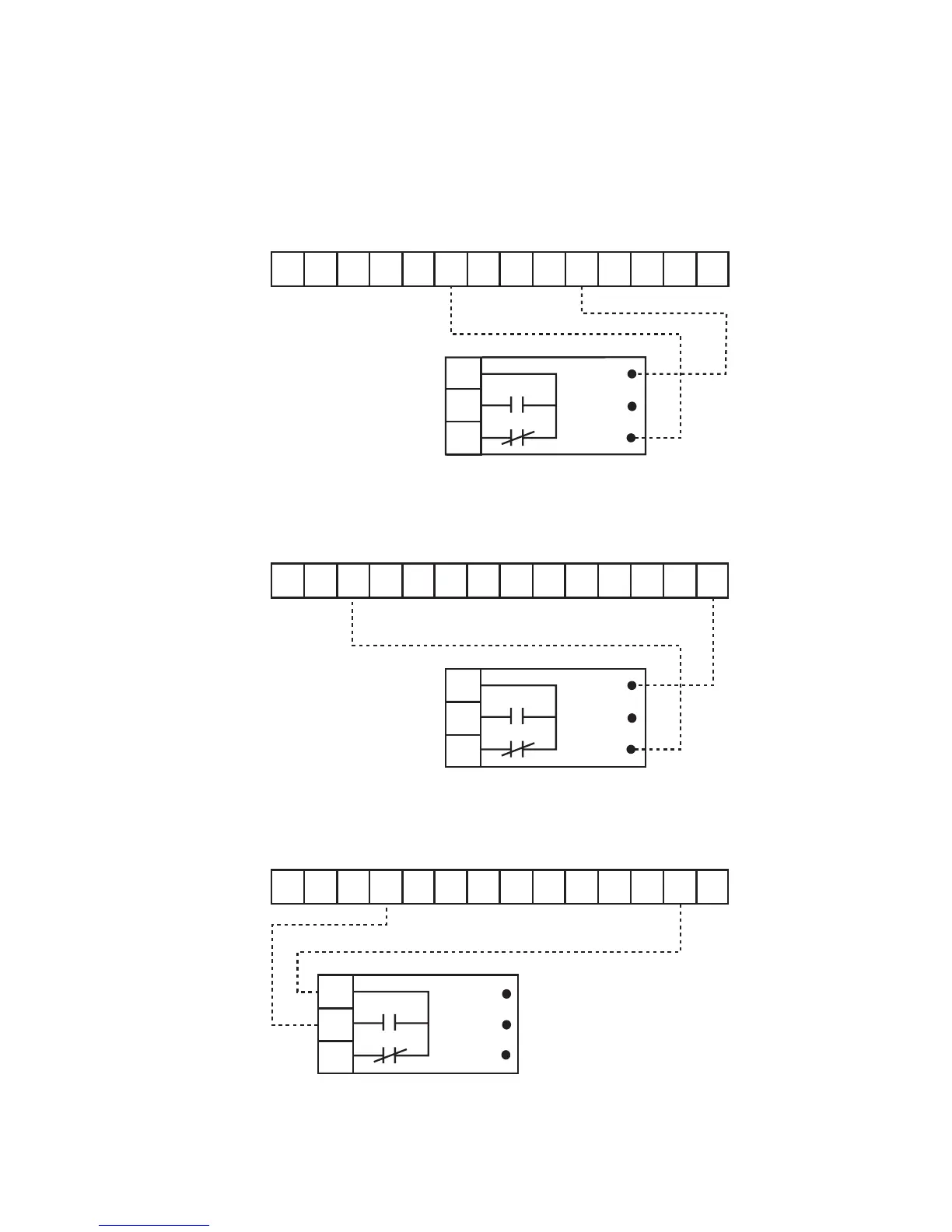

Operation: In this example the auxiliary relay contacts can be used

to indicate a fault condition. With the auxiliary relay connected as

shown, the normally open contacts will close during a fault condition.

Operation: In this example the auxiliary relay contacts can be used

to signal WSHP fan operation to another device. In this example when

the thermostat energizes the “G” terminal the auxiliary relay normally

open contacts will close.

Operation: In this example the auxiliary relay is used to interface other

control devices to the Mark IV/AC board. Using the Orange (-) and

White (+) wires, and 24vac or 24vdc, another device could be used to

start and stop the WSHP heating sequence.

can be used to provide fault signals, unit operation signals,

or to provide a means for remote equipment to control the

Mark IV/AC board. The orange, yellow, and white connec-

tions are short flying leads pre-attached to the board. The

diagrams shown are some connection examples.

IM 439 / Page 21

WSHP Mark IV/AC Board Low Voltage Terminal Strip

OW2GW1Y1 F E LUAPVRC

1

2

3

Auxiliary Relay

Orange

Yellow

White

WSHP Mark IV/AC Board Low Voltage Terminal Strip

OW2GW1Y1 F E L U A P V R C

1

2

3

Auxiliary Relay

Orange

Yellow

White

WSHP Mark IV/AC Board Low Voltage Terminal Strip

OW2GW1Y1 F E L U A P V R C

1

2

3

Auxiliary Relay

Orange

Yellow

White

Loading...

Loading...