PROTECTIVE CONTROLS

Each McQuay centrifugal is equipped with a complement of

safety controls to prevent the compressor from starting under

adverse conditions or to take the machine off-line when ab-

normal or unsafe conditions develop during operation.

In addition, there are a number of relay type devices which

operate to assure that the starting, operating and stopping

functions are carried out in proper sequence for the protec-

tion of the equipment. These relays can be identified on the

unit control diagram as

R1

R2,. etc.

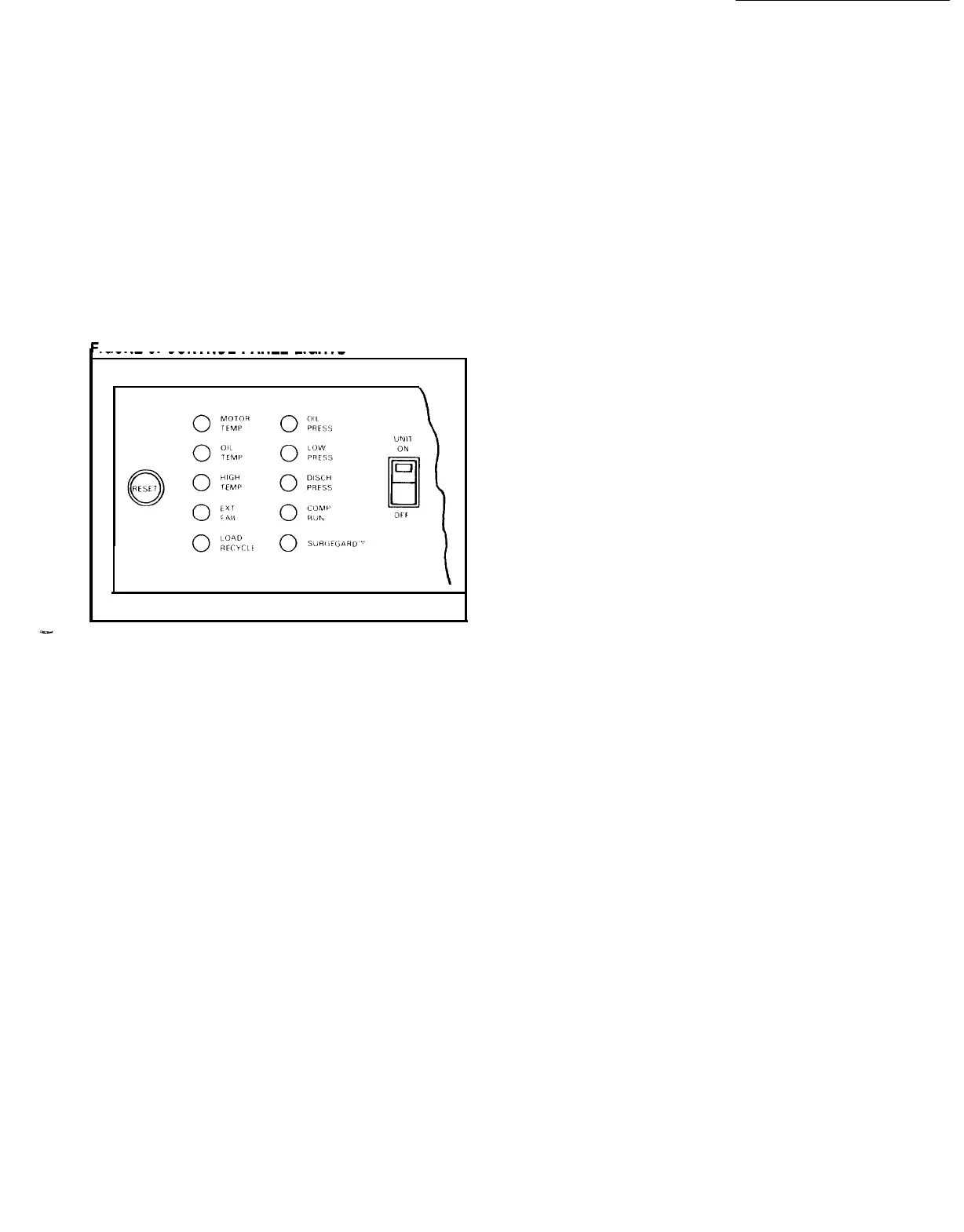

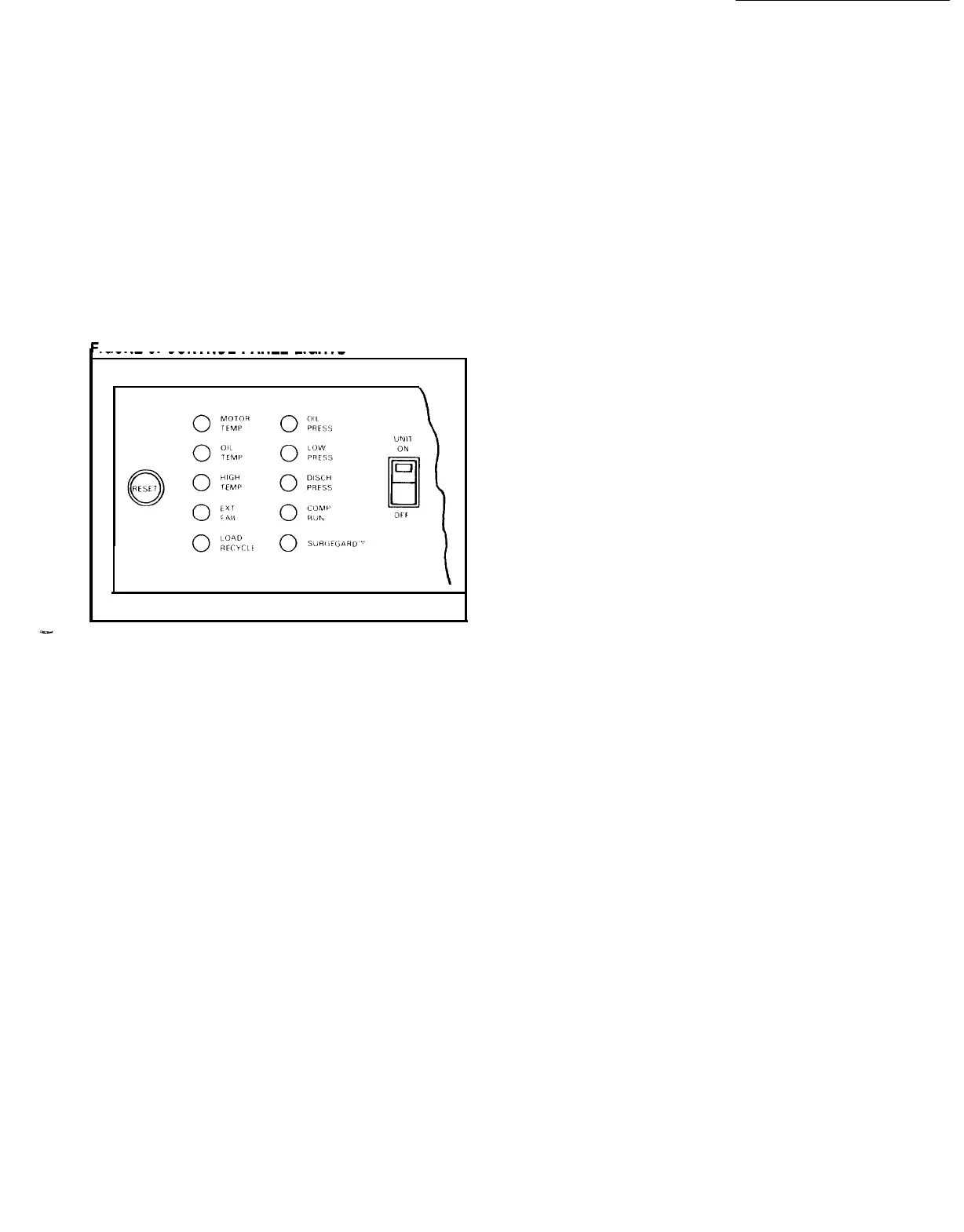

The control panel is equipped with several indicator lights

to provide the operator with a quick status condition when

the compressor is shut down. With the reference to Figure

3 it will be noted that there are eight safety signal lights to

describe some condition which has caused the compressor

to be shut down. In a fault condition only one light can be

energized at one time.

IGURE

3.CONTROL

PANELLIGHTS

Most of these indicator lights are operated when some ab-

normal condition exists with the chiller unit. Conditions such

as low suction pressure, high discharge pressure, low oil

pressure or temperature, high motor winding temperature and

surge condition may cause some damage to the equipment

if allowed to continue uncorrected.

The troubleshooting guide in Figure 13, page 20, gives the

operator a comprehensive list of fault conditions and the pro-

bable causes. This guide should be consulted whenever the

compressor is shutdown by a protective control.

Each unit is equipped with an “External Failure” light on

the control panel. When energized, this signal indicates the

compressor cannot run due to a control problem external to

the control panel. Faults in the condenser water/chilled water

circuits or in the compressor starter could trigger such an ex-

ternal failure signal. This feature helps the operator locate

control system problems. Causes and corrective actions are

further described in the troubleshooting guide.

The two most severe failures which can occur in a hermetic

centrifugal compressor are surge conditions and motor

failure. McQuay has developed highly reliable protective

systems to guard against both of these failures. An understan-

ding of each will be helpful to the operator in analyzing the

unit performance. Both Guardistor and Surgegard are safe-

ty protective systems developed by McQuay.

Guardistor Motor Protection-Positive protection against

motor overheating is provided by the Guardistor system. The

heart of the Guardistor protective circuit are the thermistors

embedded in the motor windings to sense motor winding

temperature. When the motor temperatures are normal, the

thermistors have low resistance which remains nearly cons-

tant up to a predetermined critical temperature. At this

temperature, a sharp increase in resistance causes the

Guar-

distor relay to drop out and cause the control circuit to stop

the compressor. Such failure causes a lockout mode requir-

ing manual reset.

Surgegard-McQuay

uses Surgegard to sense the occur-

rence of surge condition and to stop the compressor before

the machine is damaged. The Surgegard relay will also pre-

vent the compressor from restarting until the cause of the

malfunction has been corrected. Possible causes for surge,

or rotating stall condition, may be dirty condenser tubes or

cooling tower or pump malfunction, which acts to elevate the

system’s head. The Surgegard relay is the safety control for

the PEH/PHH 063 and larger chillers. In the

PEH/PHH050

the high temperature thermostat provides this safety func-

tion. These controls are factory set and require no field

adjustment.

SAFETY CONTROL RESET

Certain safety controls in the

PEH/PHH

control panel will lock

out automatically when operating conditions exceed trip set-

tings. As an example, if the refrigerant discharge pressure

leaving the compressor exceeds the trip setting of the high

pressure cutout switch, the compressor will be taken off-line

and cannot be restarted until the pressure has returned to

normal and the high pressure cutout has been manually reset.

In the standard control center several other safety func-

tions also lock out under abnormal operating conditions.

These controls include the low pressure cutout, high

discharge temperature thermostat, high oil temperature

switch, low oil pressure, high suction temperature

(PEH/PHH050 only), Surgegard

(PEH/PHH063-126)

and ex-

ternal system failure.

Each of these fault signals can be identified by the control

panel lights and all can be reset with the single RESET but-

ton on the front of the control panel when the fault has been

corrected.

In the event of electrical system power interruption, the

standard

PEH/PHH units will lock out and will not restart

automatically. The EXT. FAIL light will go on when power is

restored and the RESET button must be manually reset to

restore automatic chiller operation.

IM 307 I Page 7

Loading...

Loading...