46 PFS 155C - 315C OM 135

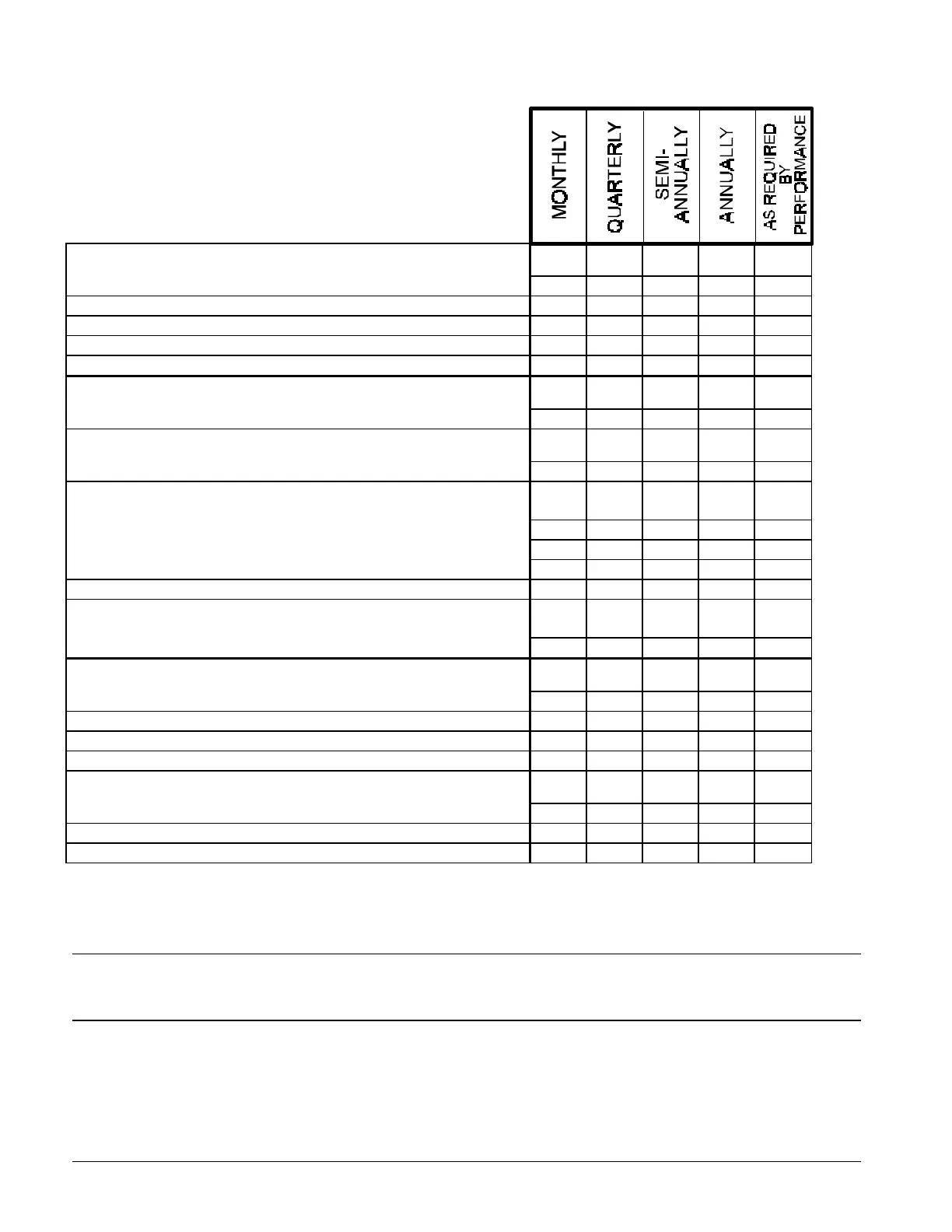

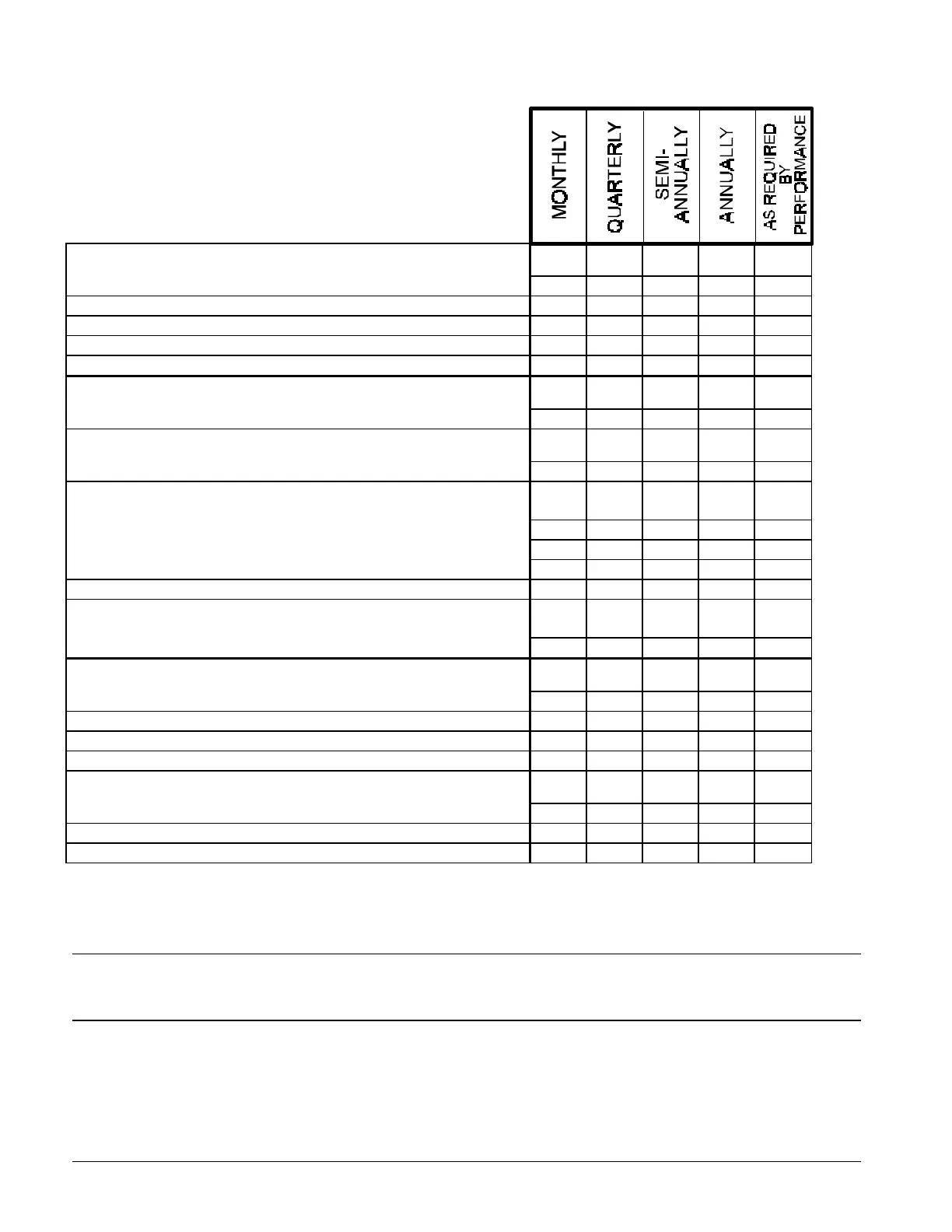

IV. EVAPORATOR

A. Performance evaluation (include water press. drop)# O

B. Test water quality X

C. Clean evaporator tubes X

D. Eddy current test --tube wall thickness X

E. Seasonal protection X

V. EXPANSION VALVES

A. Performance evaluation (observe superheat)# X

VI. COMPRESSOR - CHILLER UNIT

A. Performance evaluation O

B. Leak test:

• Compressor fittings and terminal X

• Pipe fittings X

• Oil pump line fittings X

• Vessel relief valves X

C. Check sightglasses and press. Drop across filter/dryer X

D. General appearance:

• Paint O

• Insulation O

VII. STARTERS

A. Examine contactors (hardware and operation) X

B. Verify overload setting and trip X

C. Test electrical connections X

D. Pump down controls (verify operation) X

VIII. OPTIONAL CONTROLS

A. Hot gas bypass controls (verify operation) X

B. Liquid injection controls (verify operation) X

C. Pump down control (verify operation) X

KEY:

O = performed by in-house personnel

X = performed by qualified HVAC service personnel

# = Test to be performed with compressor circuit in operation

Note: Some motors use power factor correction capacitors and others use a surge capacitor. In all cases,

capacitors must be disconnected from the circuit to obtain a useful megohmmeter reading. Failure to disconnect

capacitors will result in low readings. Only qualified electrical technicians should perform service.

Loading...

Loading...