OM 135 PFS 155C - 315C 9

Crankcase Heaters

The compressors are equipped with crankcase heaters. Crankcase heaters keep the temperature in the

crankcase high enough to prevent refrigerant from migrating to the crankcase and condensing in the

oil during the off-cycle.

Turn on power to the heaters for at least 12 hours before the compressors are started. The

crankcase temperature should be at least 80°F (26.7°C) before the system is started minimizing

lubrication problems of liquid slugging .

Service

Disconnect all power before doing any service inside the unit.

CAUTION

Service on this equipment is to be performed by qualified refrigeration personnel familiar with

equipment operation, maintenance, correct servicing procedures, and the safety hazard

inherent to this work. Causes for repeated tripping of safety controls must be investigated and

corrected.

Compressor Solenoids

The PFS unit screw compressors are equipped with three solenoids to control compressor capacity.

The solenoids are controlled by MicroTech outputs (see unit wiring diagrams). The solenoids are

energized at various compressor load conditions as indicated in Table 1.

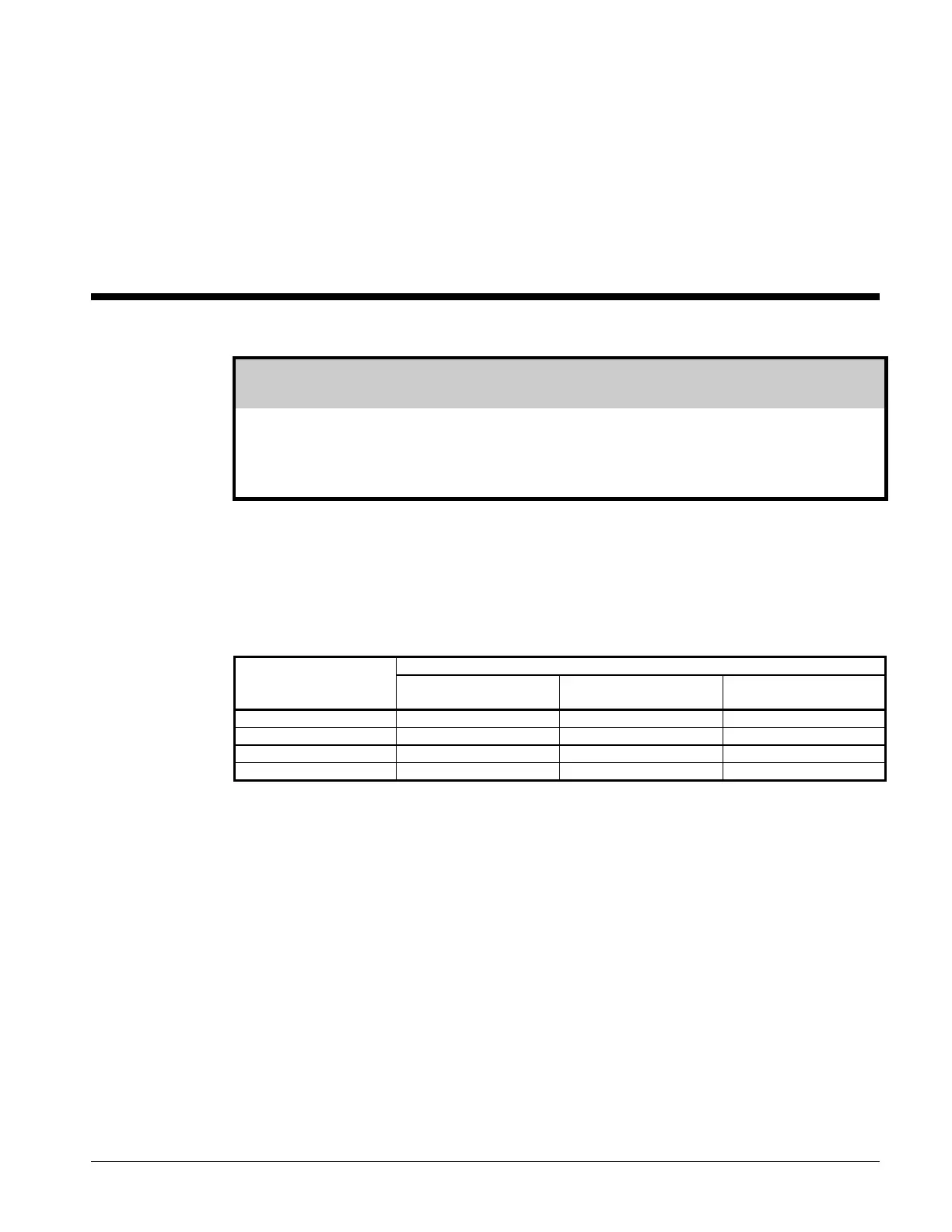

Table 1, Solenoid status

Compressor Unloading Solenoid Staus

Percent Compressor Top Bottom Front Bottom Rear

Loading Solenoid Solenoid Solenoid

100 Energized Off Energized

75 Energized Energized Off

50 Off Off Energized

25 Off Energized Off

Location of the solenoids is as follows:

• The top solenoid is on top of the compressor near the discharge end.

• The bottom solenoids are on the lower side of the compressor on the opposite end from the

terminal box. The bottom front solenoid is the one closest to the discharge end of the

compressor. The bottom rear solenoid is the one closest to the motor end of the compressor.

If the compressor is not loading properly check the solenoids to see if they are energized. A complete

check will include a check of the MicroTech output, the wiring to the solenoid and the solenoid coil

itself.

Loading...

Loading...