47

31-SAFETY DEVICES AND ALARMS

Technical Dept. - All rights reserved - Reproduction prohibited

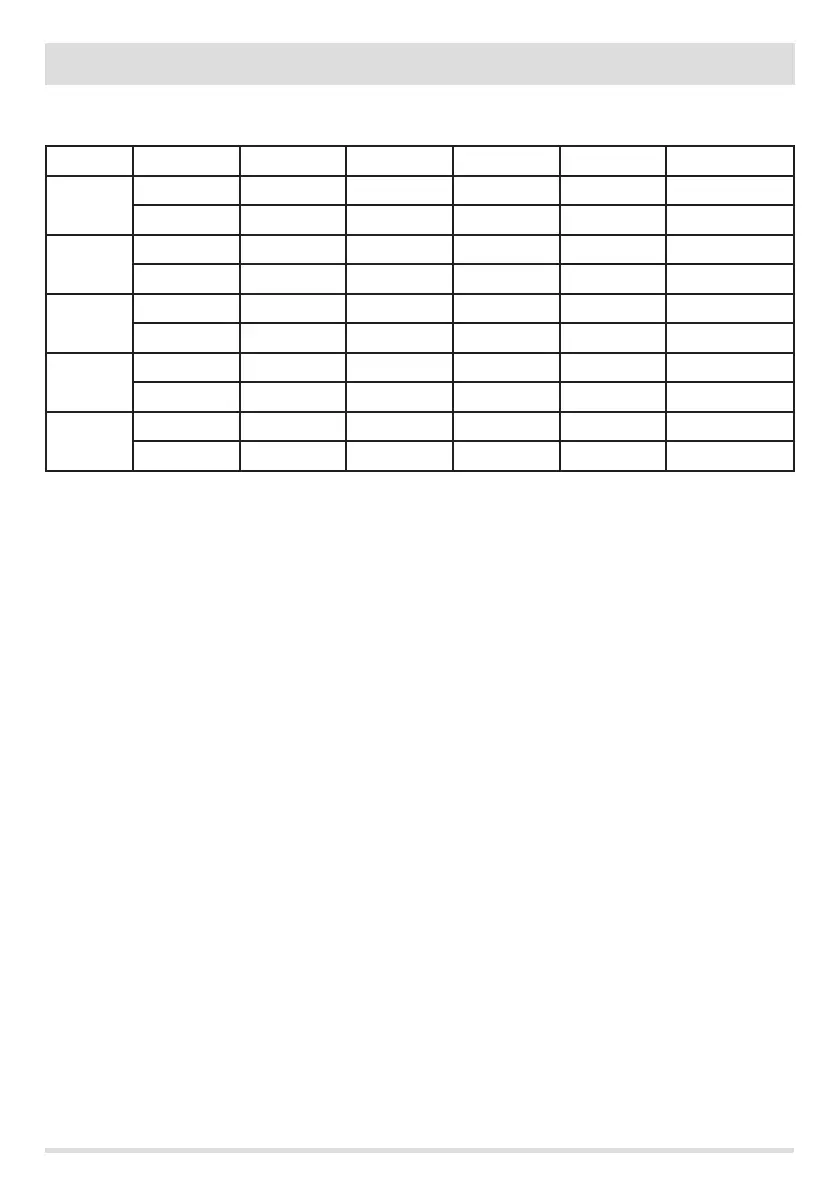

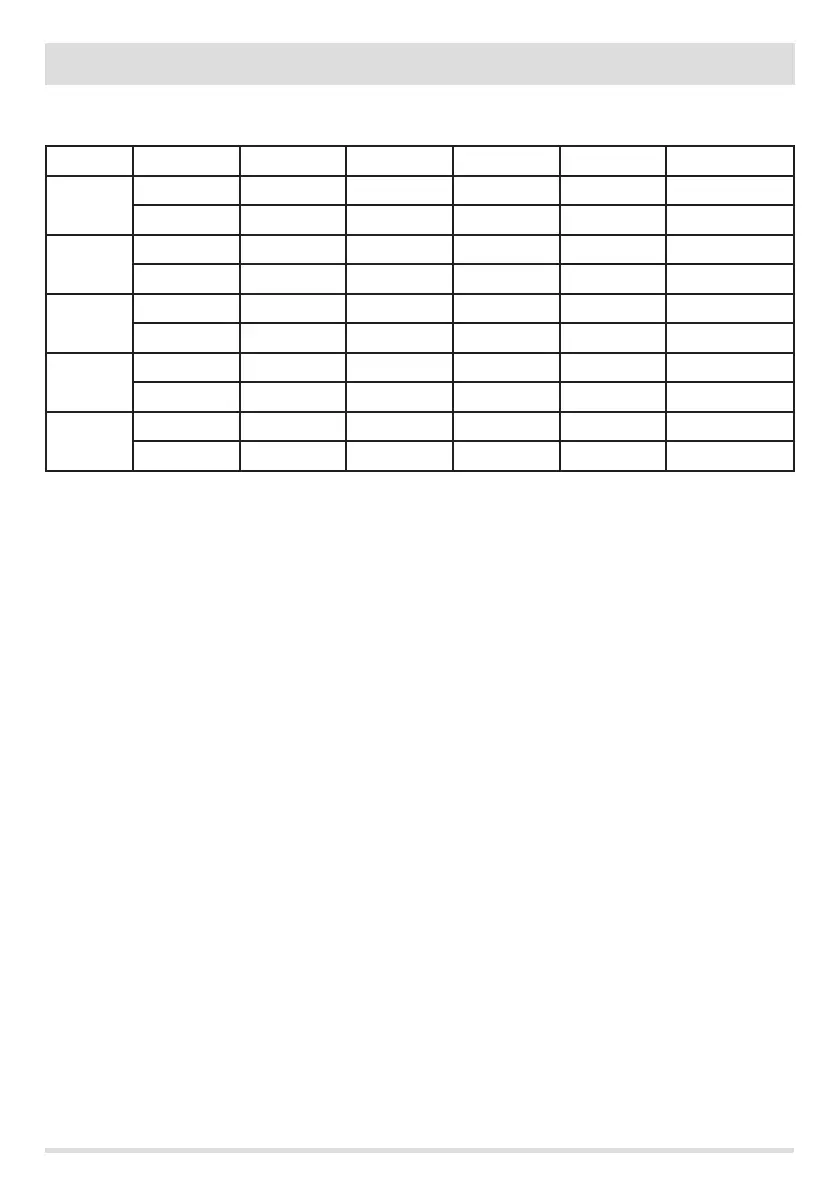

NEGATIVE PRESSURE INSIDE THE HOPPER WITH FACTORY-SET PARAMETERS AND A DRAUGHT OF 5 Pa (MINIMUM

RECOMMENDED)

POWER P1 P2 P3 P4 P5 VALUES

6 kW

13.7/14.2 Pa 15.1/15.6 Pa 17.1/17.5 Pa 19.1/19.5 Pa 22.0/22.2 Pa Draught

95°C 110°C 125°C 141°C 165°C Smoke temperature

8 kW

13.8/14.3 Pa 15.6/16.1 Pa 17.8/18.0 Pa 21.7/22.2 Pa 26.1/26.6 Pa Draught

104°C 119°C 145°C 148°C 184°C Smoke temperature

10 kW

15.9/16.3 Pa 20.4/20.9 Pa 25.8/26.3 Pa 31.8/32.3 Pa 36.5/37.0 Pa Draught

108°C °C 150°C °C 230°C Smoke temperature

12 kW

16.5/17.3 Pa 20.4/20.9 Pa 25.8/26.3 Pa 31.8/32.3 Pa 36.5/37.1 Pa Draught

118°C 127°C 155°C 172°C 195°C Smoke temperature

14 kW

17.6/18.0 Pa 19.8/20.4 Pa 23.1/23.7 Pa 28.9/29.6 Pa 37.8/38.2 Pa Draught

118°C 131°C 161°C 187°C 210°C Smoke temperature

PLEASE NOTE The indicated negative pressure readings may dier by ±1Pa based on ue gas temperature. Likewise, ue gas temperature

may dier by ±10°C based on fuel quality or appliance cleanliness.

Changing the smoke fan revolutions

In order to further improve combustion in critical conditions, you can change the percentage of the parameters for the minimum amount

of incoming combustion air. These changes can be performed upwards in the event of serious diculties in evacuating smoke and/or air

intake or downwards in the event of excessive draught of the ue.

Refer to AIR RECIPE modication instructions.

AVAILABLE VALUES

-2 -10%

-1 -5%

0 0% (default value)

+1 + 5%

+2 +10%

Loading...

Loading...