13 Malfunctions

74

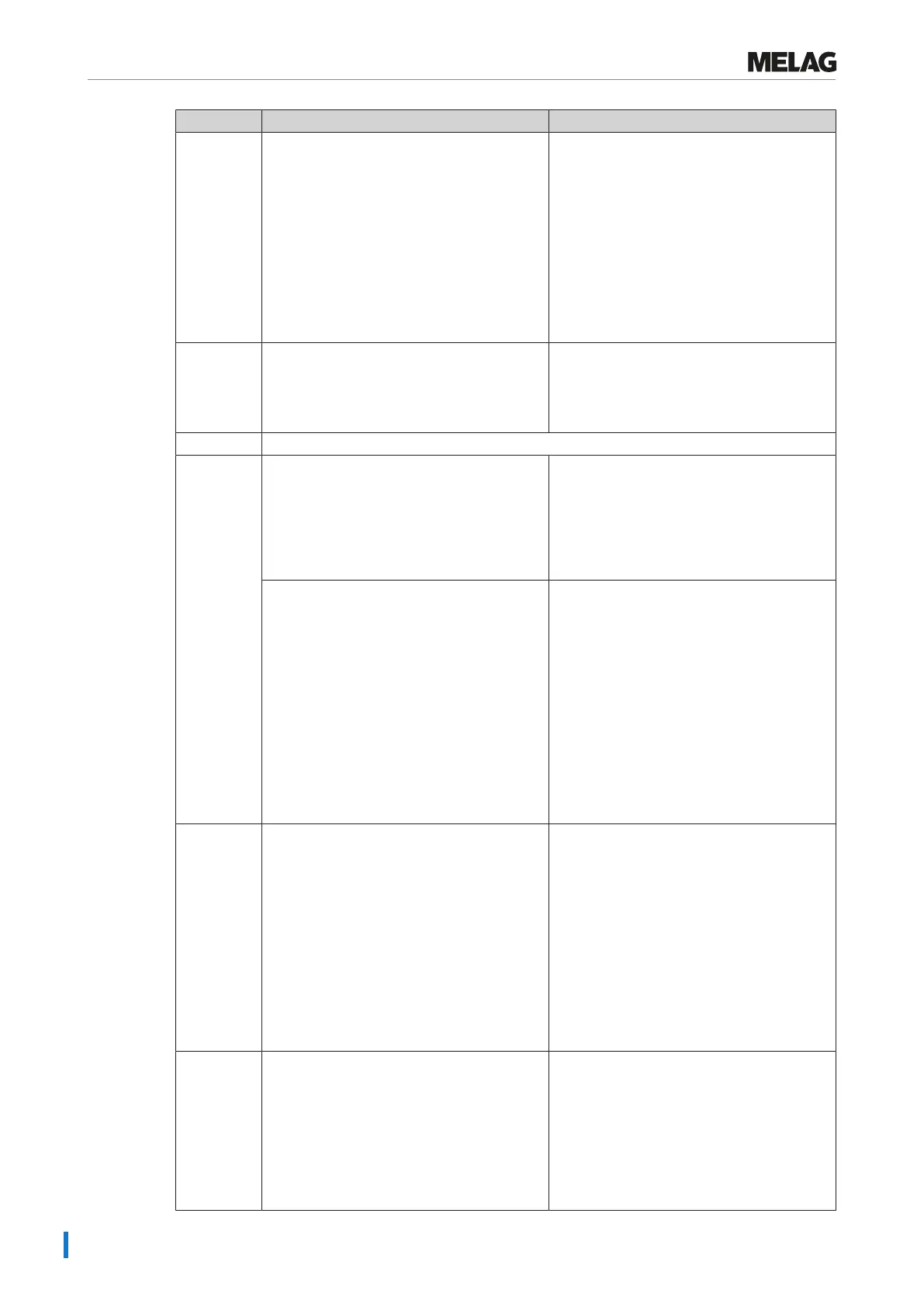

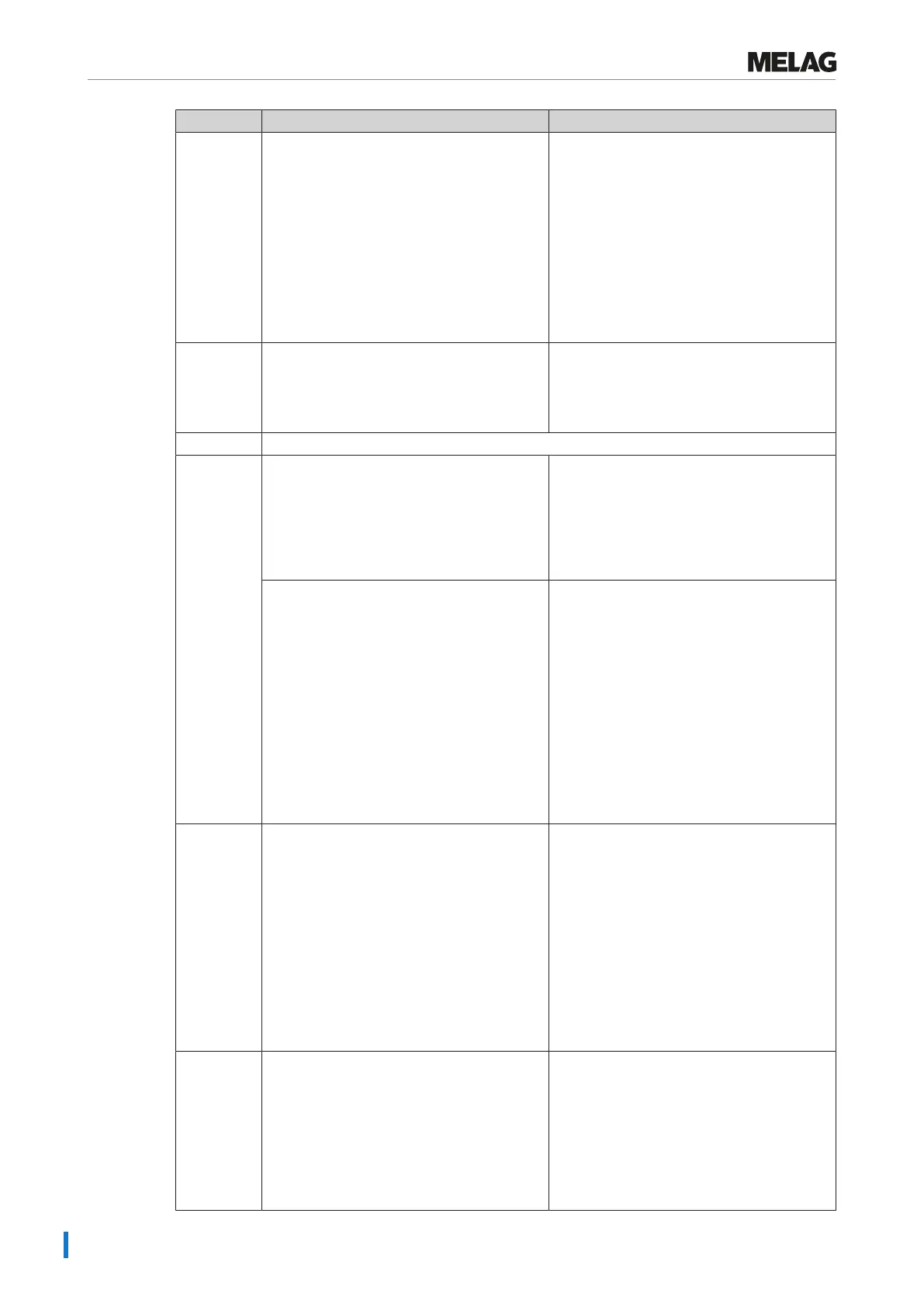

Incident Possible causes What you can do

131 a) The outlet hose is kinked or installed

sagging.

b) The siphon is blocked or the waste water

line is impeded on the building side.

c) Multiple devices have been connected to a

single siphon and imped each other during

water discharge.

d) The chamber filter "Pressure release" is

blocked.

a) Check the installation of the outlet hose.

This must be installed without kinking or

sagging and at a constant decline.

b) Check whether the building siphon or the

waste water line is are blocked.

c) If multiple devices are operated

simultaneously, we recommend the

installation of an additional siphon.

d) Remove the "Pressure release” chamber

filter and check whether it is soiled/blocked

by packaging If necessary, clean the

chamber filter.

132 The steam sterilizer is overloaded or the load

has been arranged badly.

Comply with the maximum permissible load

quantities, see Loading the steam sterilizer

[}page23]. Ensure that the load does not

come into direct contact with or covers the

steam injection nozzles.

133 see event 124

135 a) The water inflow tap for the cooling water

supply has not been opened.

b) The cooling water hose is kinked.

c) The water supply in the practice is

interrupted.

a) Open the water inflow tap completely and

check the central water inflow tap.

b) Check the installation of the cooling water

hose. It must be installed without kinking and

may not be crushed.

c) Check the shut-off valve for the building

water connection.

If a leakage water detector (water stop) is

installed:

d) The leakage water detector is without

function.

e) The inflow filter in the leakage water

detector is blocked by soiling in the building

supply.

d ) Unplug the leakage water detector control

device, wait approx. 30 s and plug it back in

again. A switching noise on the water inflow

tap (black box on the water inflow tap) must

be audible.

e) Clean the inflow filter in the leakage water

detector valve as follows:

1. Close the water inflow tap and start a

vacuum test.

2. Wait until the device displays a

malfunction message and then switch it off.

3. Unscrew the leakage water detector valve

on the water inflow tap and check the inflow

filter; clean it if necessary.

136 a) The surrounding temperature of the steam

sterilizer is too hot.

b) The ventilation slots in the side walls are

clogged/blocked.

c) The steam sterilizer is installed. The

minimum clearance to the surrounding

surfaces has not been maintained.

d) The door was left open after loading or

unloading and hot steam has escaped from

the sterilization chamber.

Switch off the steam sterilizer and allow it to

cool for approx. 1 h.

a) Comply with the requirements at the

installation location and the maximum

ambient temperature (see Technical

Manual).

b) Clean the ventilation slots and remove any

objects covering them.

c) Maintain a minimum clearance to the

surrounding surfaces (see information in the

Technical Manual).

d) Always close the door after loading or

unloading.

175 The overheat control switch of the main

heating has tripped. This notification may be

issued in alternation with E176: ACOUT 02

open.

1. Switch off the steam sterilizer and press

the reset button overheat control on the fore

side of the steam sterilizer at the bottom

right-hand side (behind the cover) back in.

2. Acknowledge the malfunction message.

3. Switch off the steam sterilizer and back on

again and then perform an empty sterilization

run if necessary. Then the steam sterilizer is

ready for operation.

Loading...

Loading...