I. 3

Technical Specifications

for the ML-200-ST Central

Unit Applicator

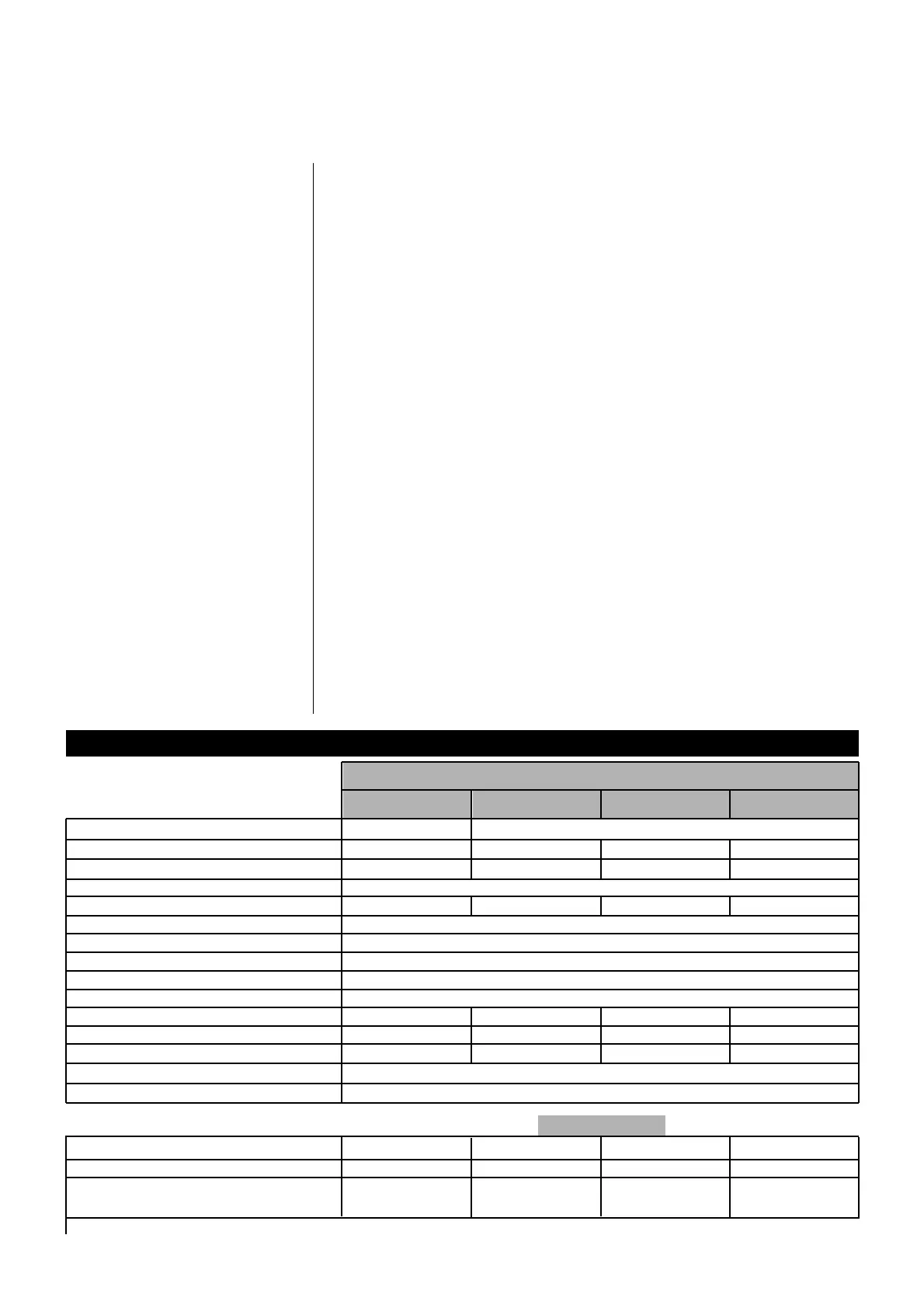

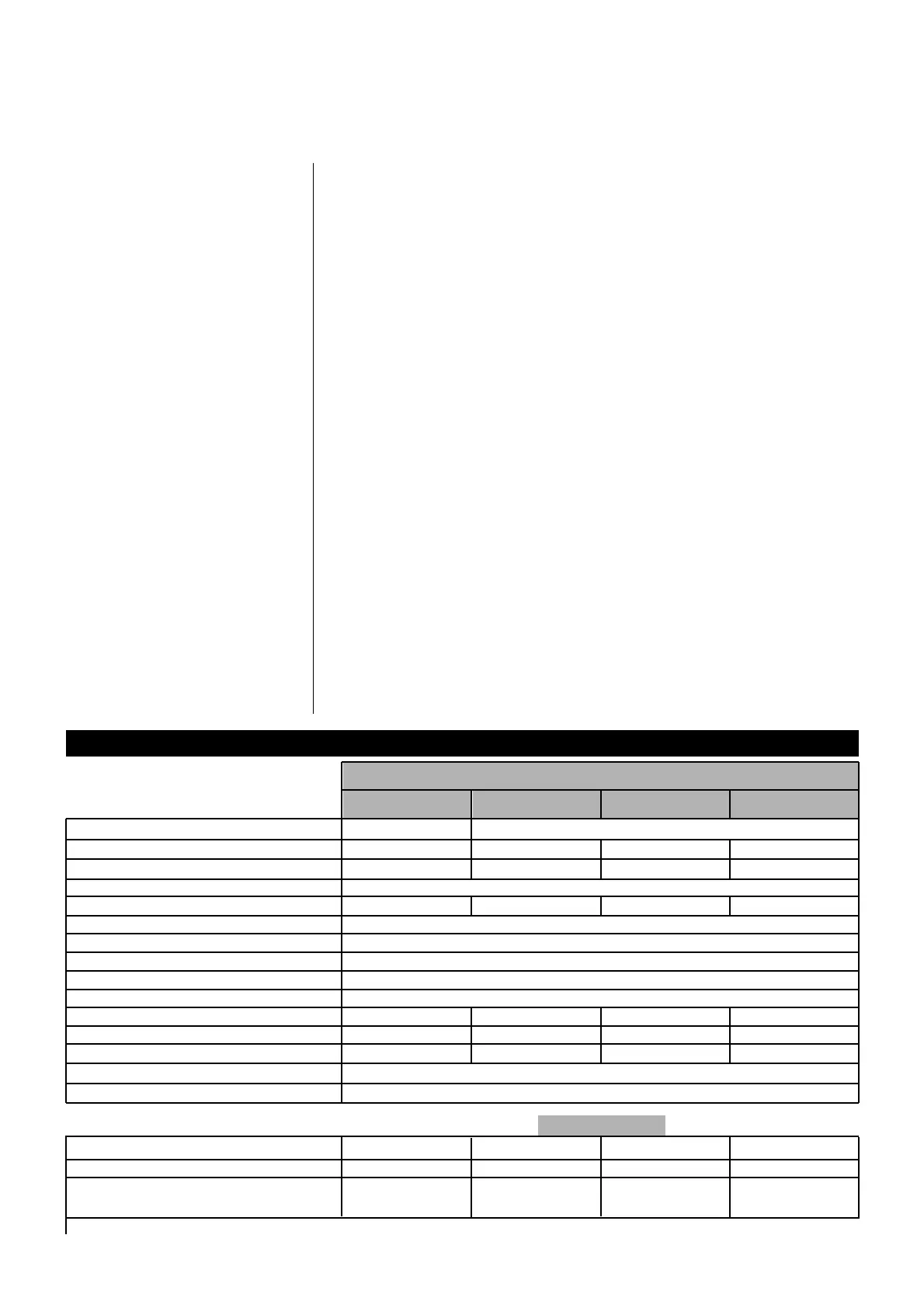

TECHNICAL SPECIFICATIONS

CENTRAL UNIT APPLICATOR

ML-242-ST

OPTIONS

ML-260-ST ML-210-ST ML-225-ST

Electrical supply

Tank Volume

Fusion capacity*

Pump capacity*

Number of hydraulic/electrical outlets

Range of viscosities

Range of temperatures

Thermal precision

Pneumatic feeding pressure

Hydraulic relation

Tank electrical power

Maximum electrical power for system

Weight Kg.

Protection point

CE/EMC approval

* Depending on adhesive

230V single-phase 230V single-phase 230V Threephase; 400V Threephase+ N.

4050 cm

3

6900 cm

3

11000 cm

3

25000 cm

3

6 Kg/h 9,8 Kg/h 16,5 Kg/h 29,2 Kg/h

29,6 Kg/h

2 2/4 2/4/6 2/4/6

180 -35.000 c.p.s.

70 - 230°C / 158 - 446 °F

±0.5°C / ±0.9°F

0,5 - 6 Kg/cm

2

13,624

2.000 W. 2.000 W. 3.000 W. 3.000 W.

3.600 W. 3.600/3.600/7.900 W. 3.600/3.600/10.200 W 3.600/3.600/10.200 W

30 37 54 75

IP 54

Yes

Level detector w. low level alarm outlet

400 V without neutral

Gasification system for use of easily

oxidized adhesives

••••

••

••••

THERMAL SPECIFICATIONS

The compact construction of the solidary PUMP-TANK block with a bottom pump

offers total control of the Hot-Melt temperature throughout the hydraulic circuit. At the

same time a rapid fusion speed has been achieved while using minimal electrical

consumption.

Due to the hermetically sealed tank via floating lid, smoke escape is avoided and

the adhesive is protected from early oxidation. A wide- angle lid opening allows

adhesive loading from any position. The ample-sized loading port makes loading Hot-

Melt easy.

PNEUMATIC AND PUMPING SPECIFICATIONS

The pump system features a continuous steady flow thanks to a well-designed

block of tank-pump-pneumatic system:

• The operation via piston pump with the exclusive compensation large volume

valve allows a totally uniform hydraulic pressure for the adhesive.

• The patented pneumatic assembly has a fully mechanized design which features

strength and durability. The high-speed piston change significantly helps maintain

continuous steady flow of the adhesive.

• The recirculation of the Hot-Melt avoids burnt residue build-up as well as wear on

the mechanical components.

SAFETY

It features constant self-monitoring and display of damaged components as well as

protection against overheating.

The independent signal for the input electrical power at external supply to the

Parent Machine Interlock allows control of the Parent Machine start-up when the

adhesive has reached running temperature.

Three highly performing filter systems for the adhesive.

Loading...

Loading...