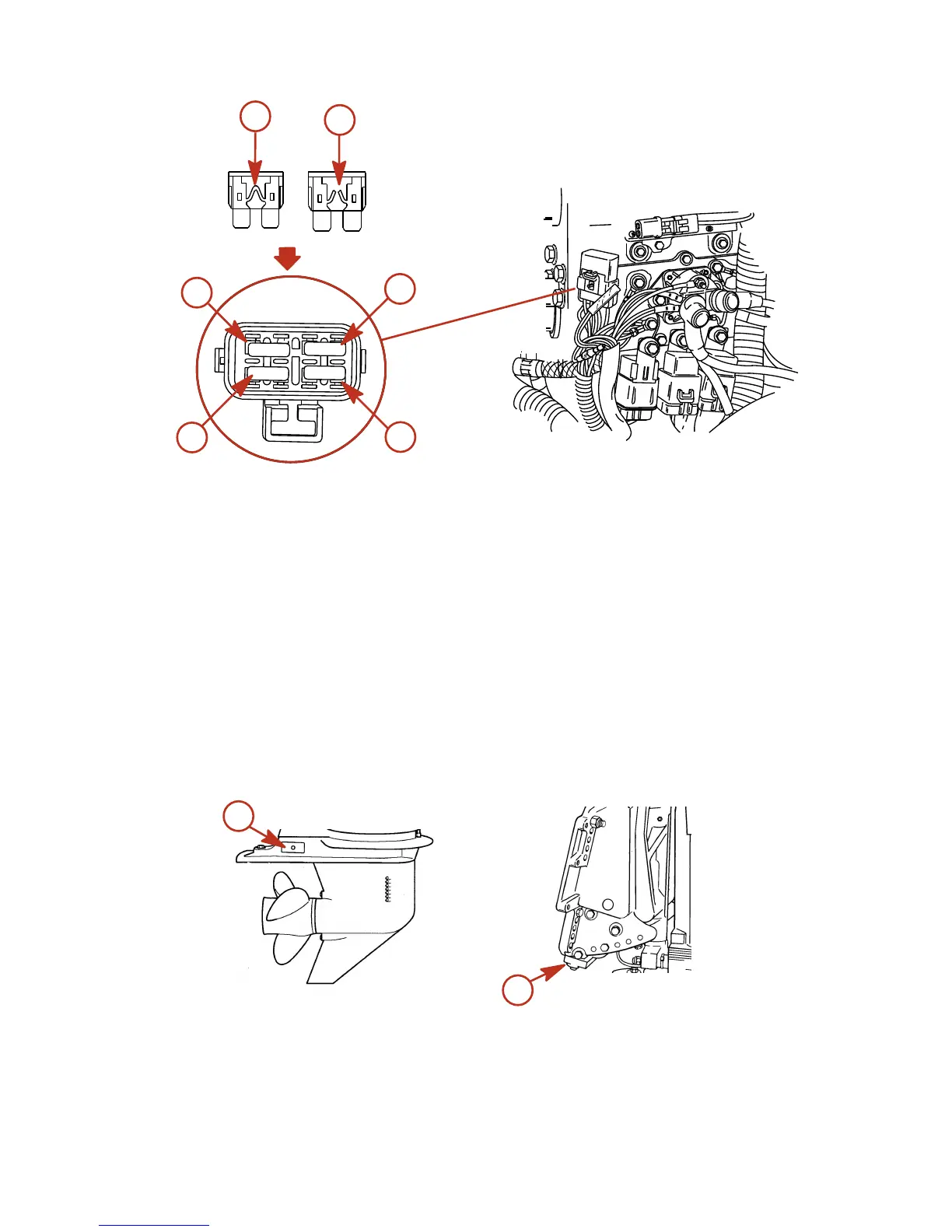

a - Good fuse

b - Blown fuse

c - SmartCraft data bus circuit - 5 AMP fuse

d - Accessories - 20 AMP fuse

e - Ignition coil circuit - 20 AMP fuse

f - Electric fuel pump/ECM driver power/oil pump circuit - 20 AMP fuse

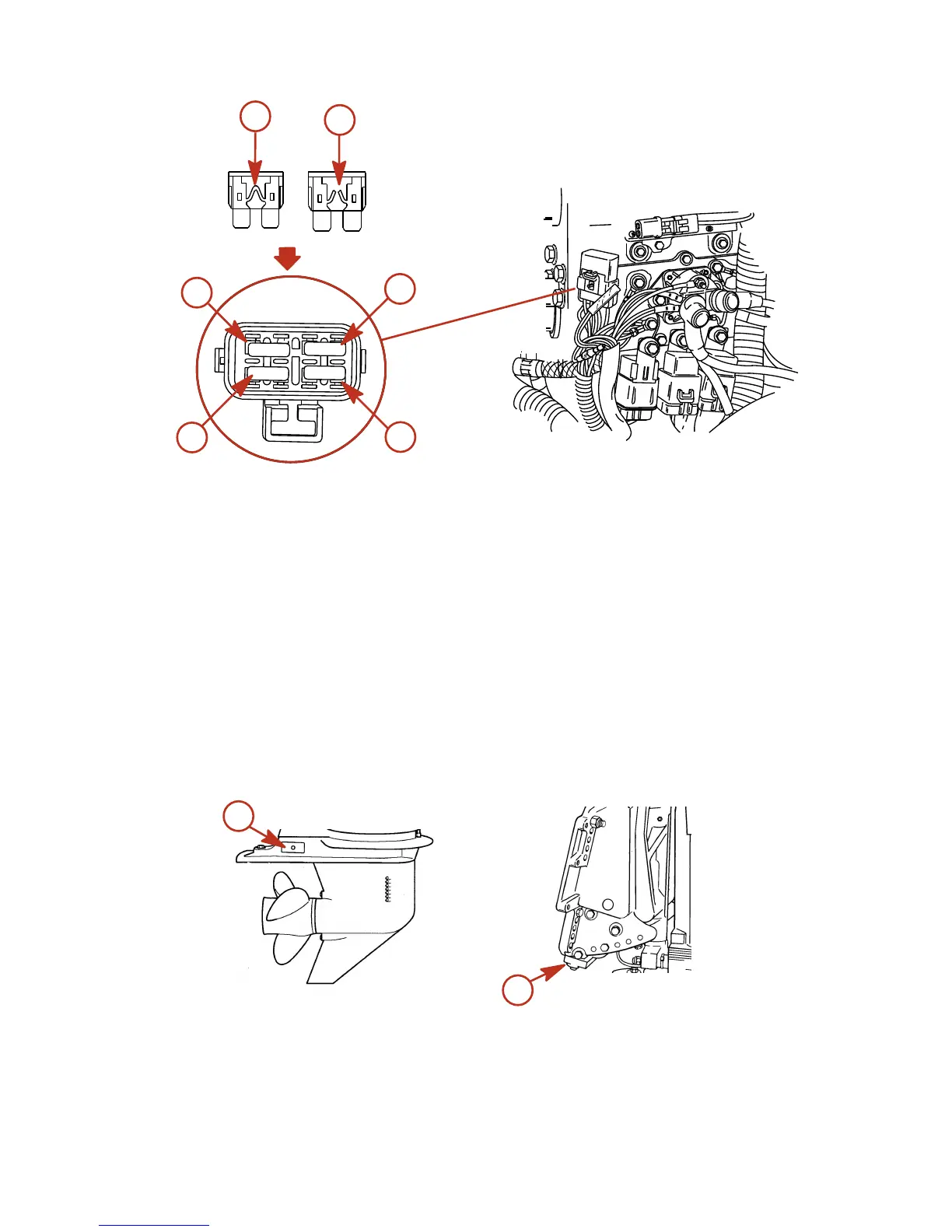

Corrosion Control Anode

Your outboard has corrosion control anodes at different locations. An anode helps protect the outboard against

galvanic corrosion by sacrificing its metal to be slowly eroded instead of the outboard metals.

Each anode requires periodic inspection, especially in salt water which will accelerate the erosion. To maintain

this corrosion protection, always replace the anode before it is completely eroded. Never paint or apply a protective

coating on the anode as this will reduce effectiveness of the anode.

The gearcase has two corrosion control anodes, one on each side. A third anode is installed on the bottom of the

transom bracket assembly.

a - Anode (2) on each side of gearcase

b - Anode on transom bracket assembly

Battery Inspection

The battery should be inspected at periodic intervals to ensure proper engine starting capability.

Loading...

Loading...