TIMING, SYNCHRONIZING & ADJUSTING

Page 2C-4 90-883728 JULY 2001

Timing

All timing adjustments are controlled by the Electronic Control Module (ECM). No external

mechanical timing adjustments can be made.

Actual engine timing can be monitored by using a Digital Diagnostic Terminal (DDT).

Ignition timing at idle, whether in gear or in neutral, will vary.

The ECM will use ignition timing to maintain an rpm of approximately 700 in neutral and

625 in forward gear. An engine that is cold will require more timing advance than an engine

that is at normal operating temperature.

Engine timing at idle should be between 1° to 7° ATDC with the engine at normal operating

temperature.

Engine timing at 5000 rpm should be approximately 18° to 20° BTDC for all models.

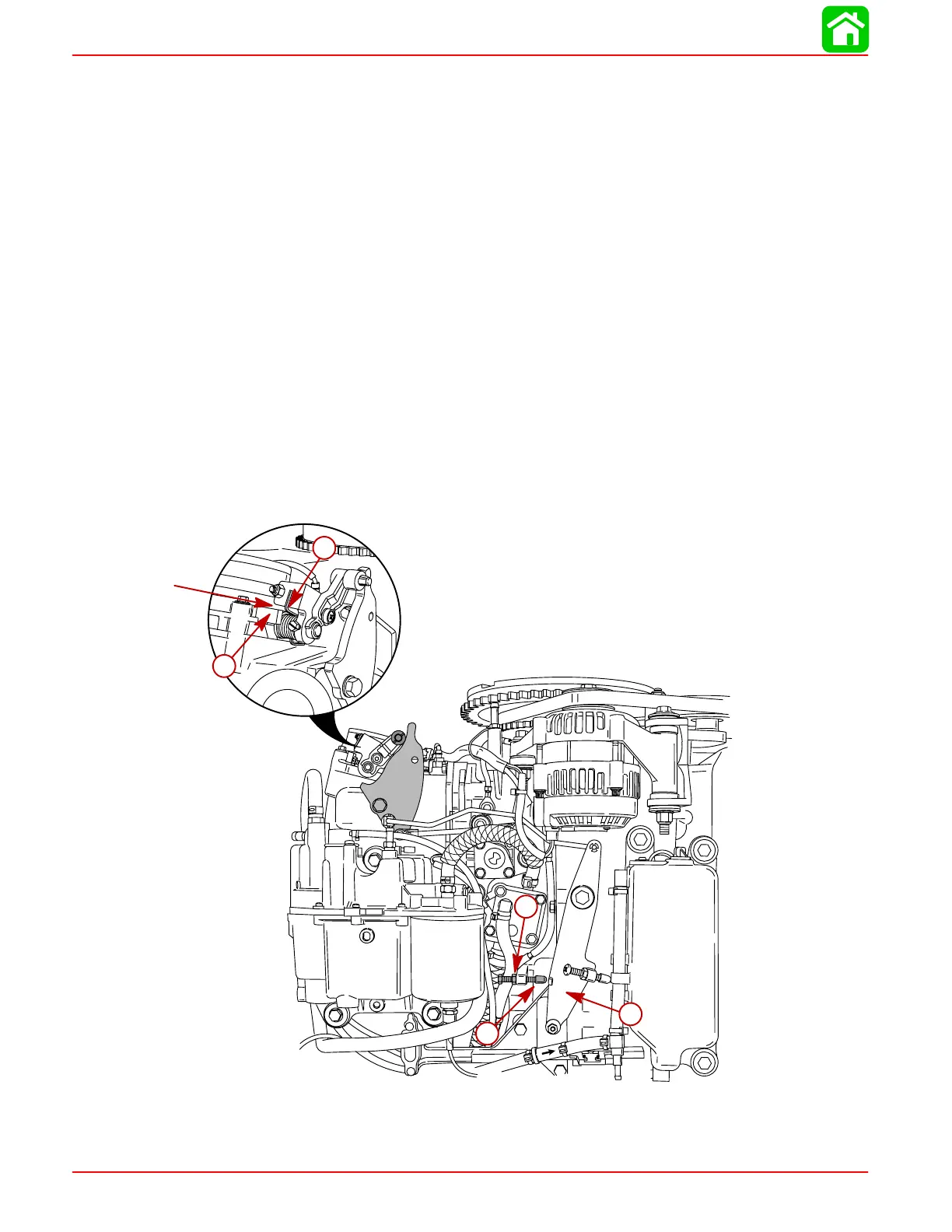

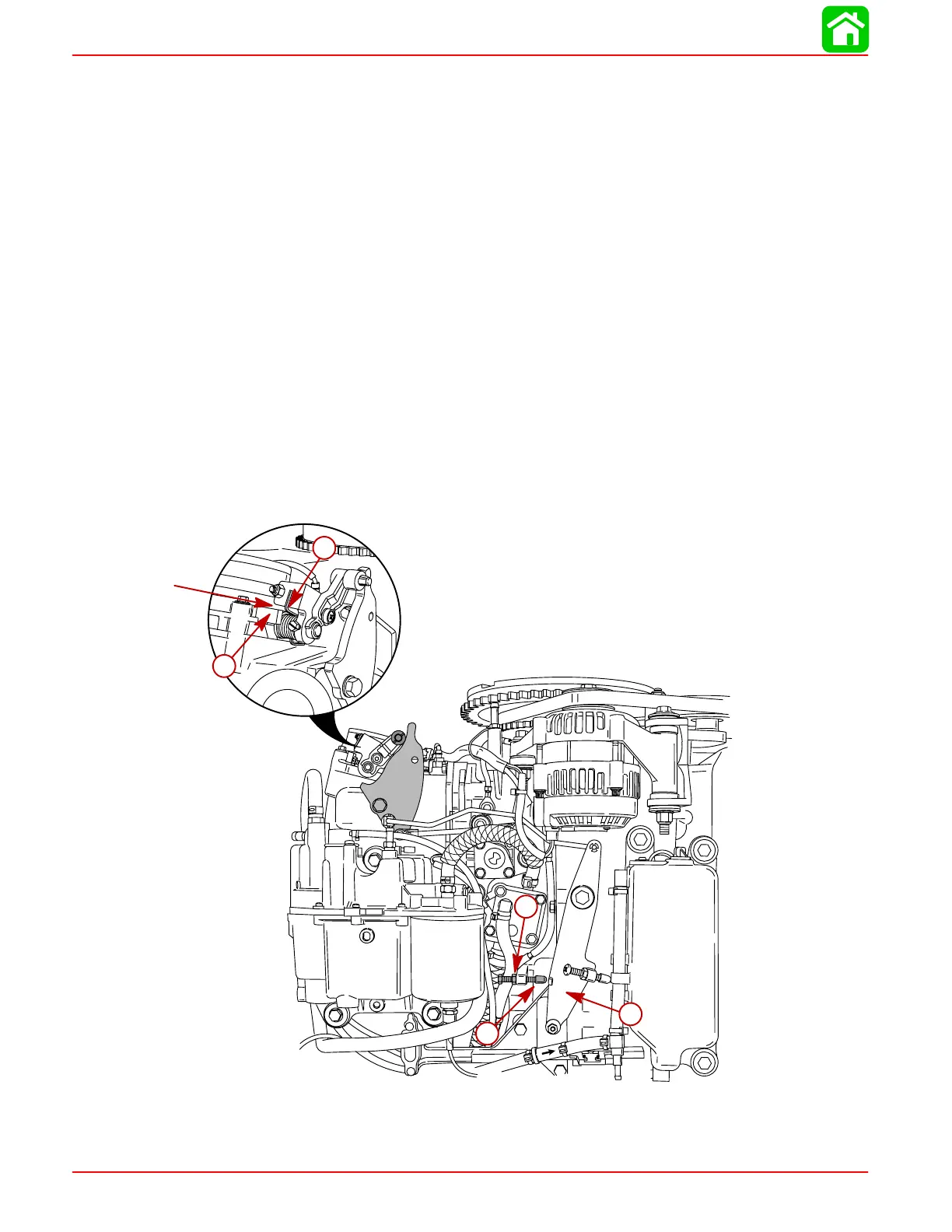

Maximum Throttle Adjustment

1. Hold throttle arm (a) against full throttle stop screw (b). Adjust full throttle stop screw

to allow full throttle valve opening, while maintaining a clearance of 0.020 in. (0.50

mm) between arm (c) of throttle shaft and stop (d) on throttle assembly. Tighten lock-

nut (e).

2. Check for slight free play (roller lifter from cam) between roller and cam at full throttle

to prevent linkage from binding. Readjust full throttle stop screw, if necessary.

58900

a

b

d

e

c

0.020 in.

(0.050 mm)

a-Throttle Arm

b-Full Throttle Stop

Screw

c-Throttle Shaft Arm

d-Stop

e-Locknut

Loading...

Loading...