POWERHEAD

90-883728 JULY 2001 Page 4A-61

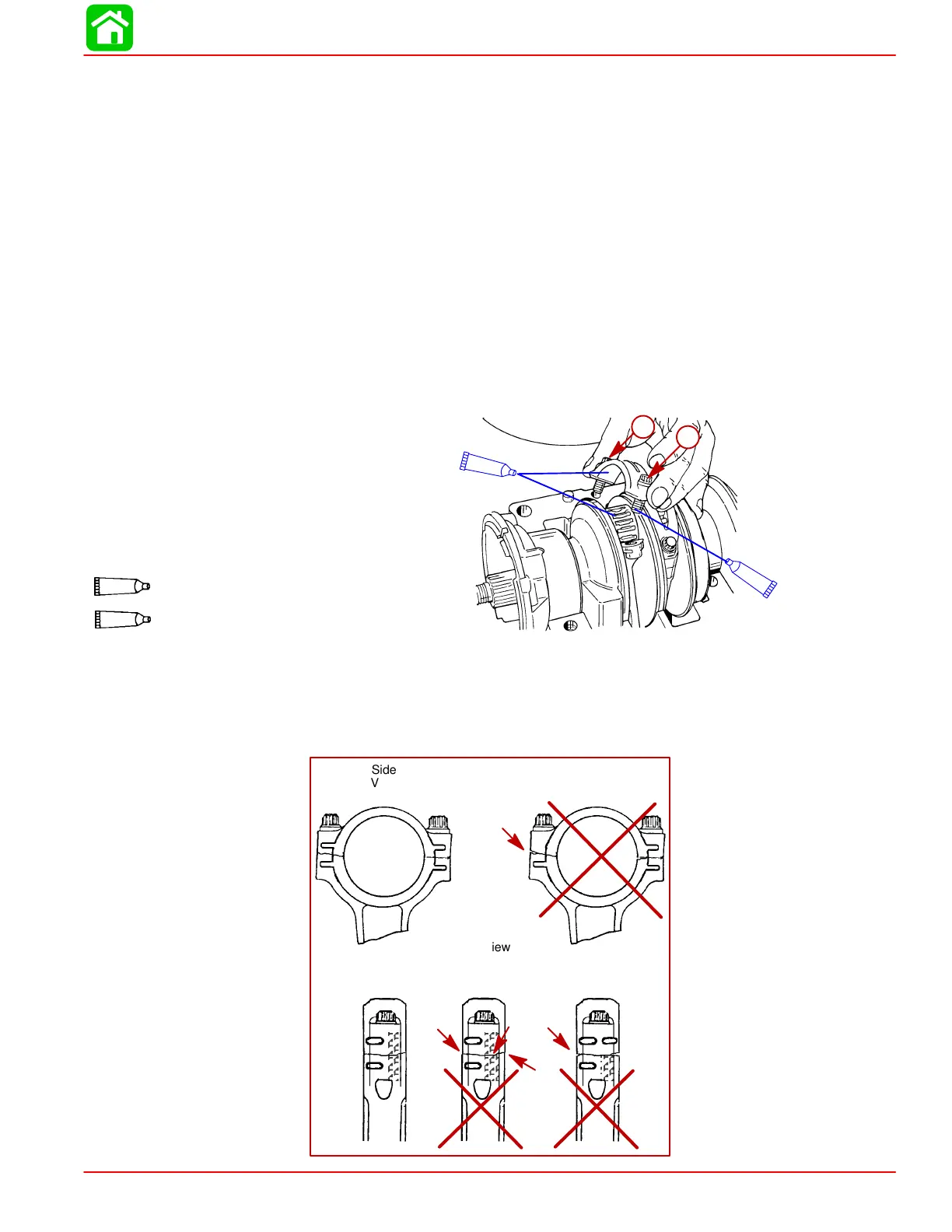

10. Apply Quicksilver 2-4-C with Teflon to bearing surface of connecting rod and, install

bearing assembly as shown.

IMPORTANT: It is recommended that connecting rod bolts not be reused.

11. Place connecting rod cap on connecting rod. Apply light oil to threads and face of con-

necting rod bolts. Thread connecting rod bolts finger-tight while checking for correct

alignment of the rod cap as shown.

IMPORTANT: Connecting rod and connecting rod caps are matched halves. Do not

torque screws before completing the following procedure.

• Run a pencil lightly over ground area.

• If pencil stops at fracture point, loosen bolts, retighten, and check again.

NOTE: If you still feel the fracture point, discard the rod.

12. Tighten connecting rod bolts (using a 5/16 in. - 12 point socket). First torque to 15 lb.

in. (1.7 N·m) then 30 lb. ft. (41 N·m). Turn each bolt an additional 90° after 2nd torque

is attained. Recheck alignment between rod cap and rod as shown.

a

a

51850

a

a

95

2-4-C With Teflon

95

14

2 Cycle Outboard Oil

14

a-Connecting Rod Screws

13. Rotate crankshaft several times (using powerhead stand) to assure free operation (no

binds and catching).

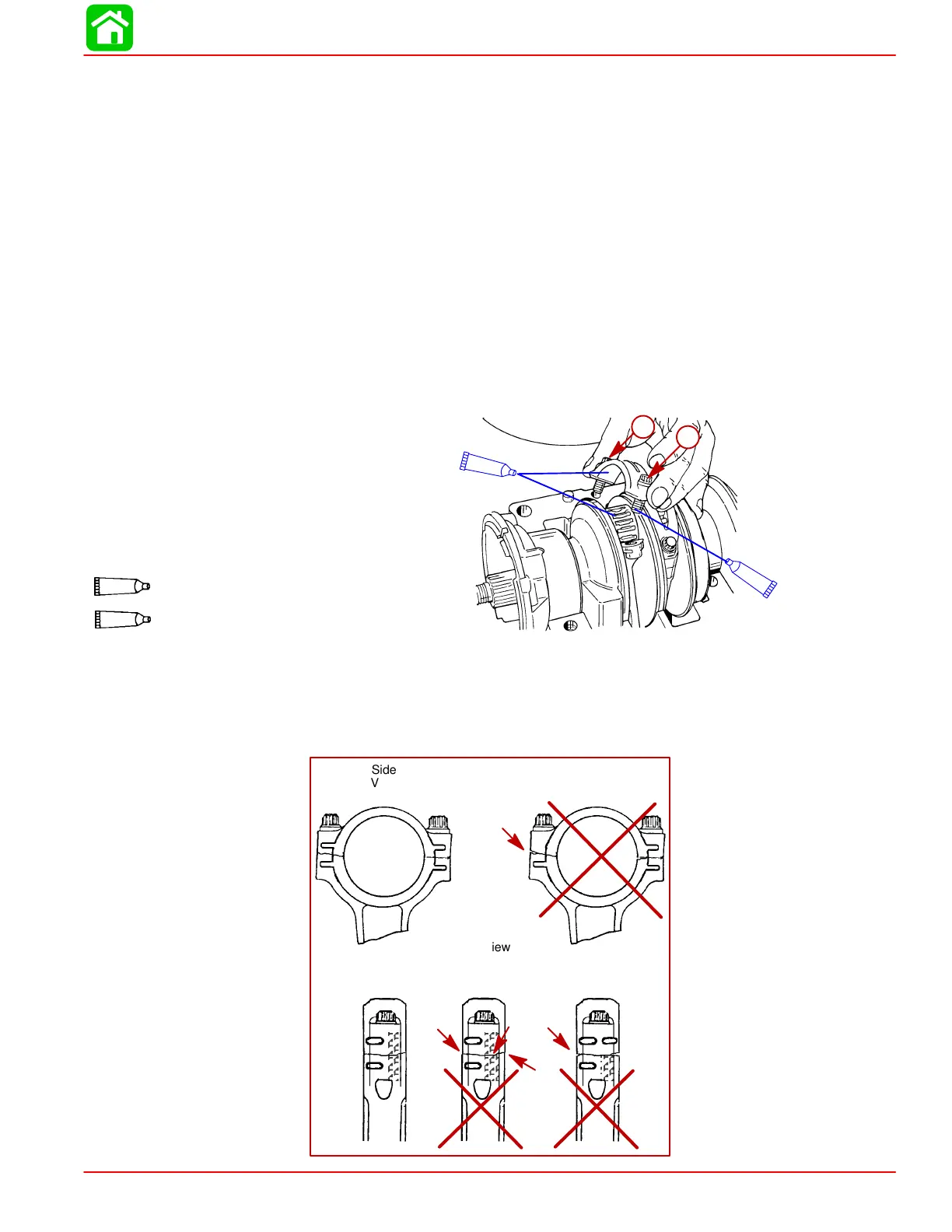

Check each connecting rod cap for correct alignment. If not aligned, a ridge can be seen

or felt at the separating line as shown below. Correct any misalignment.

Side

View

Correct

End

View

Correct

Side View

Incorrect-Cap

on Backwards

End View

Incorrect-Cap

on Backwards

End View

Incorrect-

Not

Aligned

Loading...

Loading...