RIGHT HAND NON-RATCHETING

Page 6A-24 90-883728 JULY 2001

NOTE: FORWARD gear must be removed first BEFORE removing driveshaft needle

bearing.

IMPORTANT: Discard driveshaft needle bearing after removal. (Bearing cannot be

reused.)

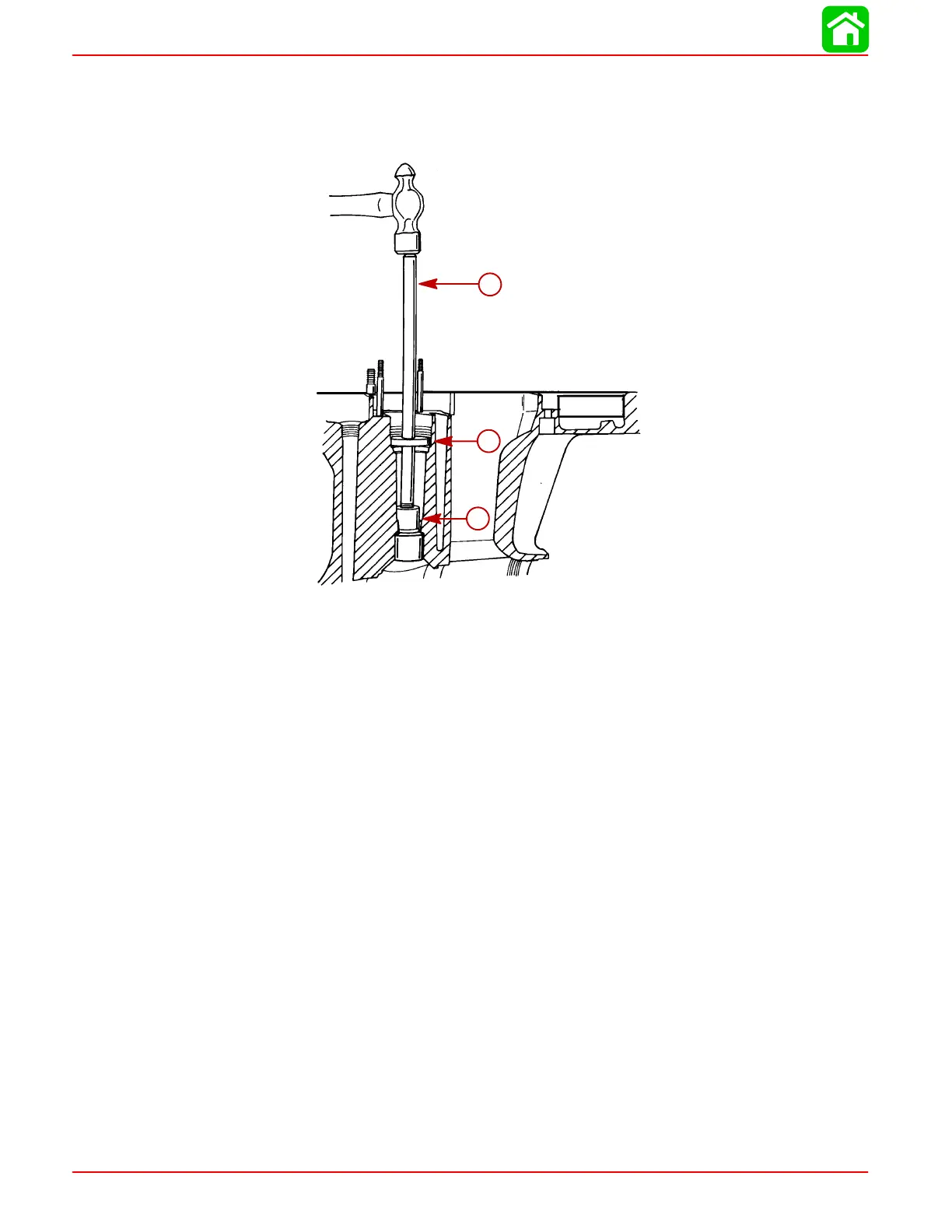

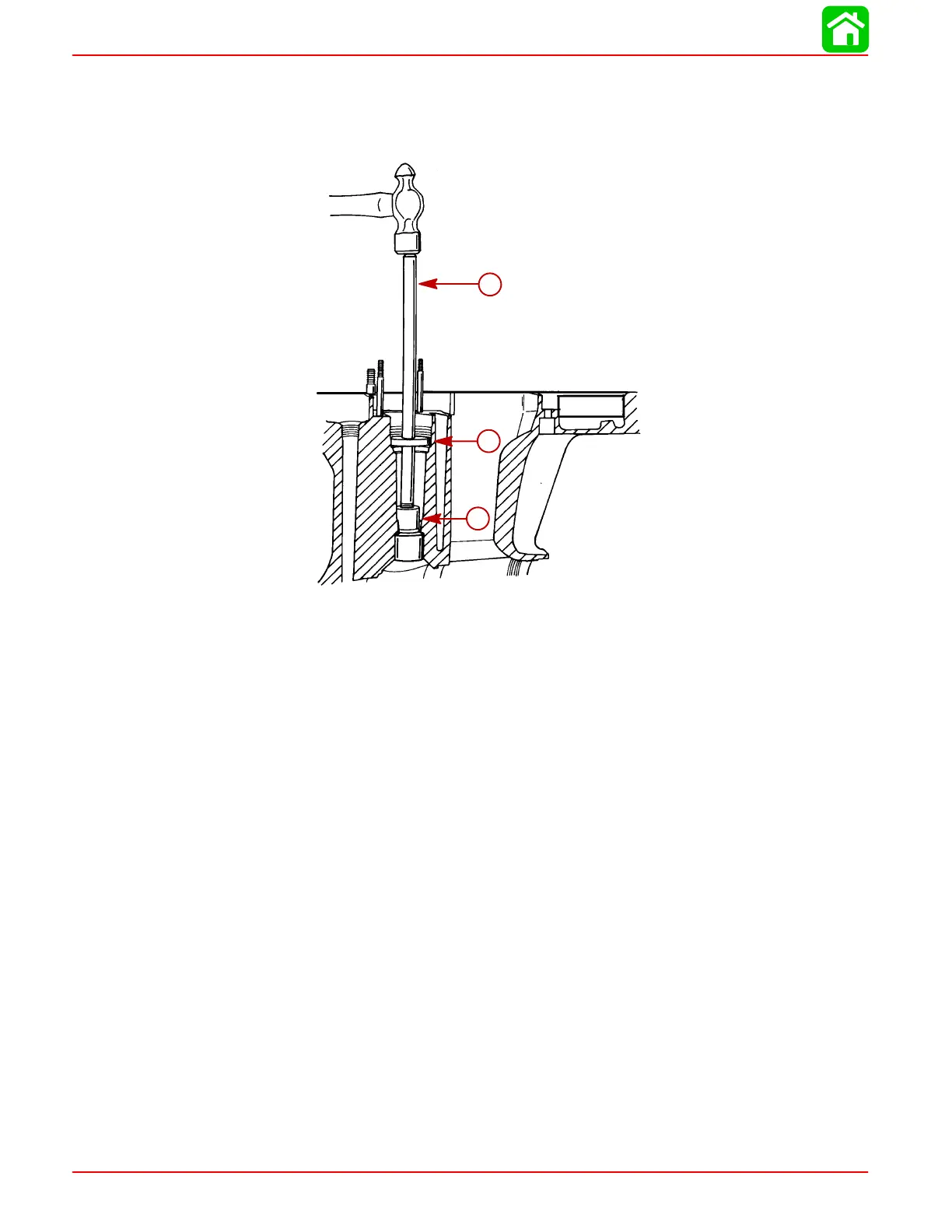

c

b

a

51869

a

b

c

a-Mandrel (91-37263)

b-Pilot* (91-36571)

c-Driver Rod* (91-37323)

*From Bearing Removal and Installation Kit (91-31229A7)

CLEANING AND INSPECTION

1. Clean driveshaft, tapered bearing and race, and pinion gear with solvent. Dry with

compressed air. DO NOT allow driveshaft bearing to spin while drying.

2. Inspect pinion gear for pitting, grooves, scoring, uneven wear and/or discoloration

from overheating. Replace pinion gear, if any of the above conditions are found.

3. Inspect driveshaft needle bearing surface (area just above pinion gear splines) for pit-

ting, grooves, scoring, uneven wear and/or discoloration from overheating. Replace

driveshaft and driveshaft needle bearing, if any of the preceding conditions are found.

4. Inspect driveshaft to crankshaft splines for wear. Replace driveshaft if wear is exces-

sive.

5. Inspect tapered bearing race for pitting, grooves, scoring, uneven wear and discolor-

ation from overheating. Replace tapered bearing and race as a set, if any of the pre-

ceding conditions are found.

6. Inspect driveshaft for groove(s) where water pump base oil seals contact shaft. Re-

place driveshaft if groove(s) are found.

Loading...

Loading...