LEFT HAND NON-RATCHETING

Page 6B-30 90-883728 JULY 2001

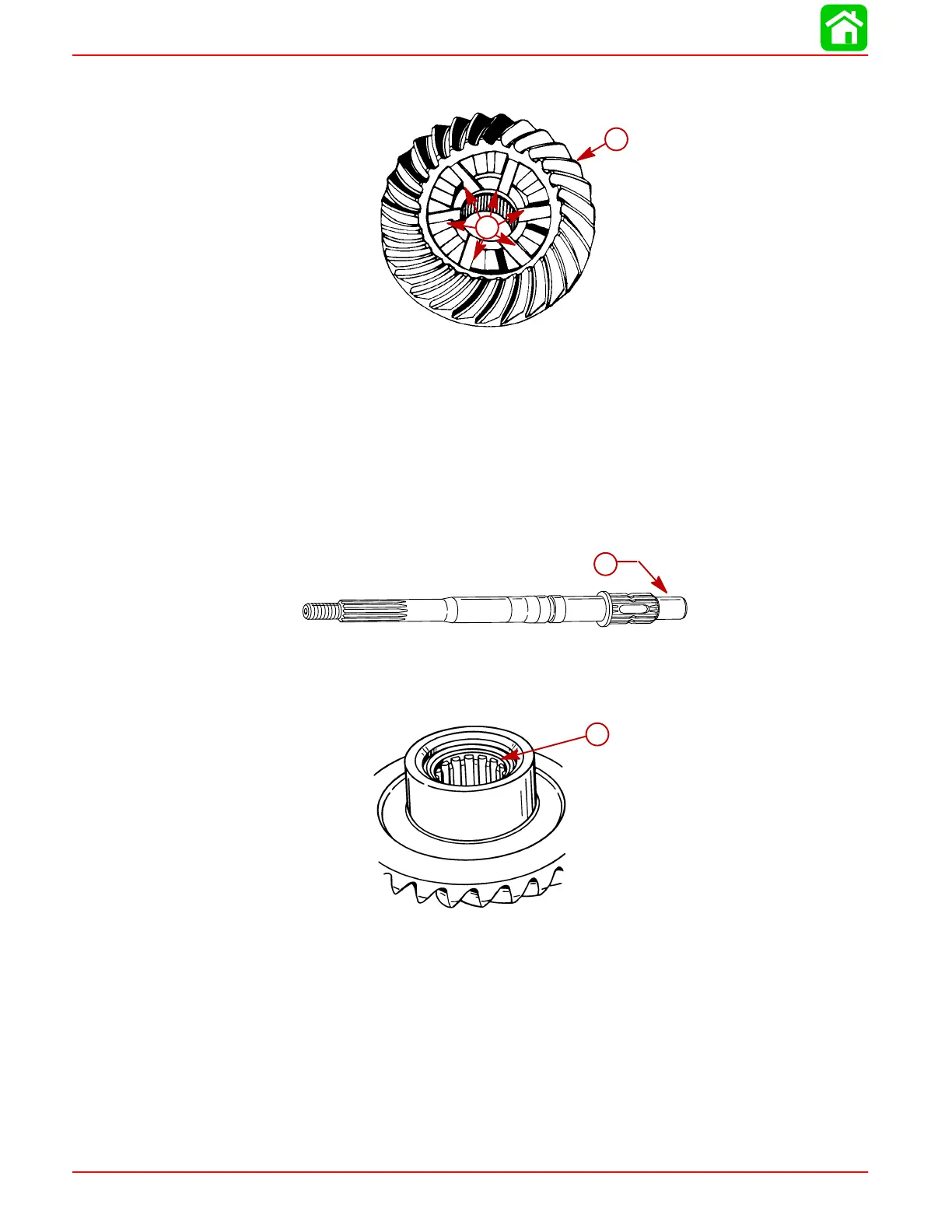

3. Check clutch jaws on reverse gear for damage. Replace reverse gear if damage is

found.

23351

a

b

a

a-Reverse Gear Teeth

b-Clutch Jaws

NOTE: The needle bearings in the reverse gear should not be removed unless damage

has been found. Inspect to ensure that all of the needles are present and in position.

Needles that have been dislodged may be snapped back into place as long as no damage

has occurred to the bearing cage.

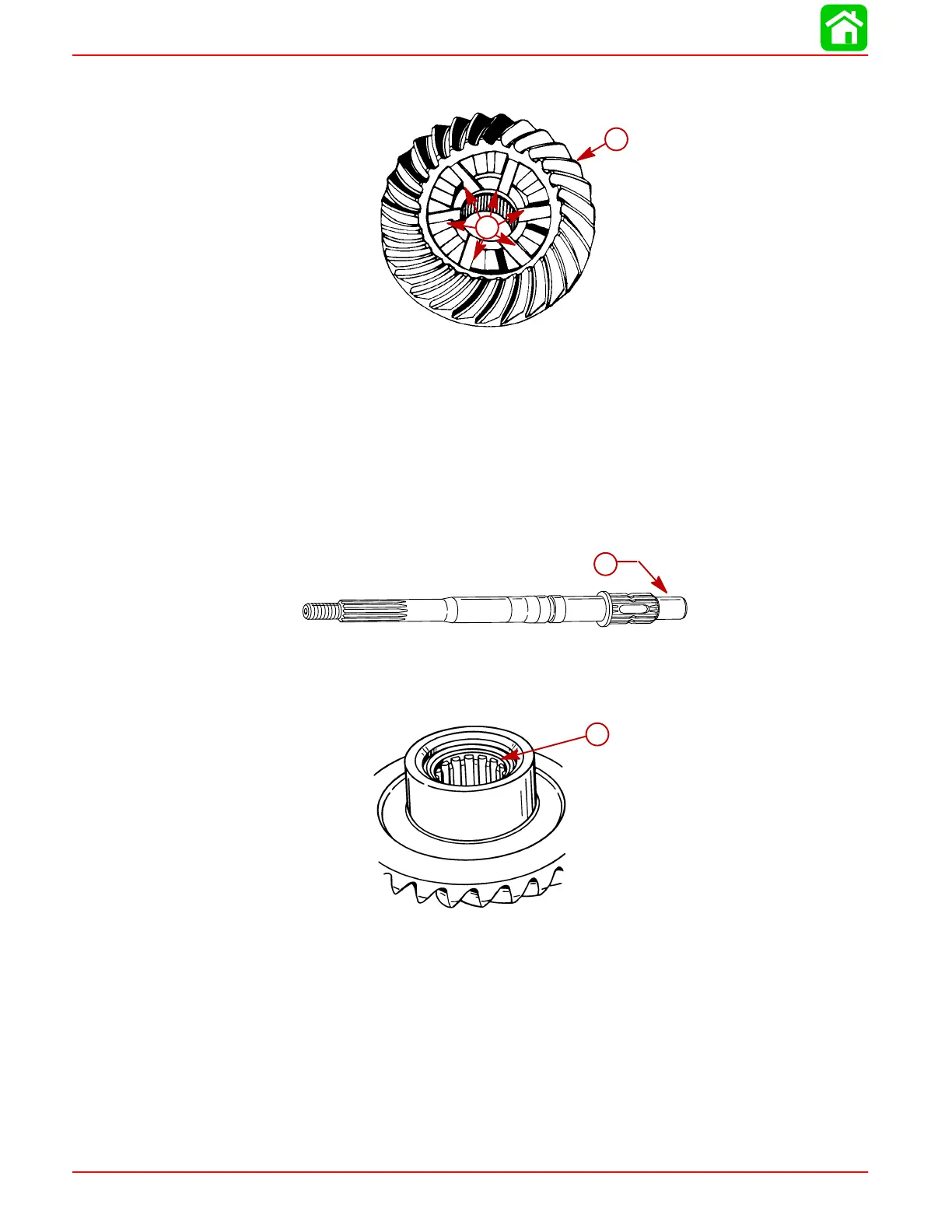

4. Inspect the needle bearings on the inside of the reverse gear and the bearing surface

on the propeller shaft. If either the needle bearings or the bearing surface of the pro-

peller shaft is pitted grooved, worn unevenly, discolored from overheating or has em-

bedded particles, replace the propeller shaft and needle bearing in the reverse gear.

a

a

a-Reverse Gear Needle Bearing Contact Area

5. If reverse gear needle bearing is found to be damaged, place reverse gear in a press

and use mandrel 91-63569 to press bearing out of gear.

50778

a

a

a-Bearing

Gear Housing

CLEANING AND INSPECTION

1. Clean gear housing with solvent and dry with compressed air.

2. Check gear housing carefully for impact damage.

3. Check for loose fitting bearing adaptors and needle bearings.

NOTE: If bearing adaptors have spun in gear case, gear housing must be replaced.

4. Inspect bearing carrier cover nut retainer threads in gear housing for corrosion dam-

age and/or stripped threads.

Loading...

Loading...