• Change engine oil and replace the oil filter. The oil should be changed

more often when the engine is operated under adverse conditions, such

as extended trolling. Refer to Changing Engine Oil and Filter.

• Check the engine mounted water‑separating low‑pressure fuel filter for

water or contaminants. Replace the filter if required. Refer to Fuel

System.

• Check the boat mounted water‑separating fuel filter for the presence of

water or contaminants. Drain the water or replace the filter if required.

•

Remove the propeller and lubricate the propeller shaft. Refer to Propeller

Replacement.

• Inspect the thermostat visually for corrosion or a broken spring. Ensure

that the thermostat closes completely at room temperature—dealer

service.

• Check the outboard mounting fasteners that fasten the outboard to the

boat transom. Tighten the fasteners to the specified torque—dealer

service.

Description

Nm lb‑in. lb‑ft

Outboard mounting locknuts and

bolts ‑ standard boat transom

75 – 55.3

Outboard mounting locknuts and

bolts ‑ metal lift plates and setback

brackets

122 – 90

• Check corrosion control anodes. Check more frequently when used in

saltwater. Refer to Corrosion Control Anode.

•

Drain and replace gearcase lubricant. Refer to Gearcase Lubrication.

•

Inspect battery. Refer to Battery Inspection.

• Saltwater usage: Remove and inspect spark plugs for corrosion and

replace as necessary. Apply Anti‑Seize Compound only on threads of

spark plug prior to installation. Refer to Spark Plug Inspection and

Replacement.

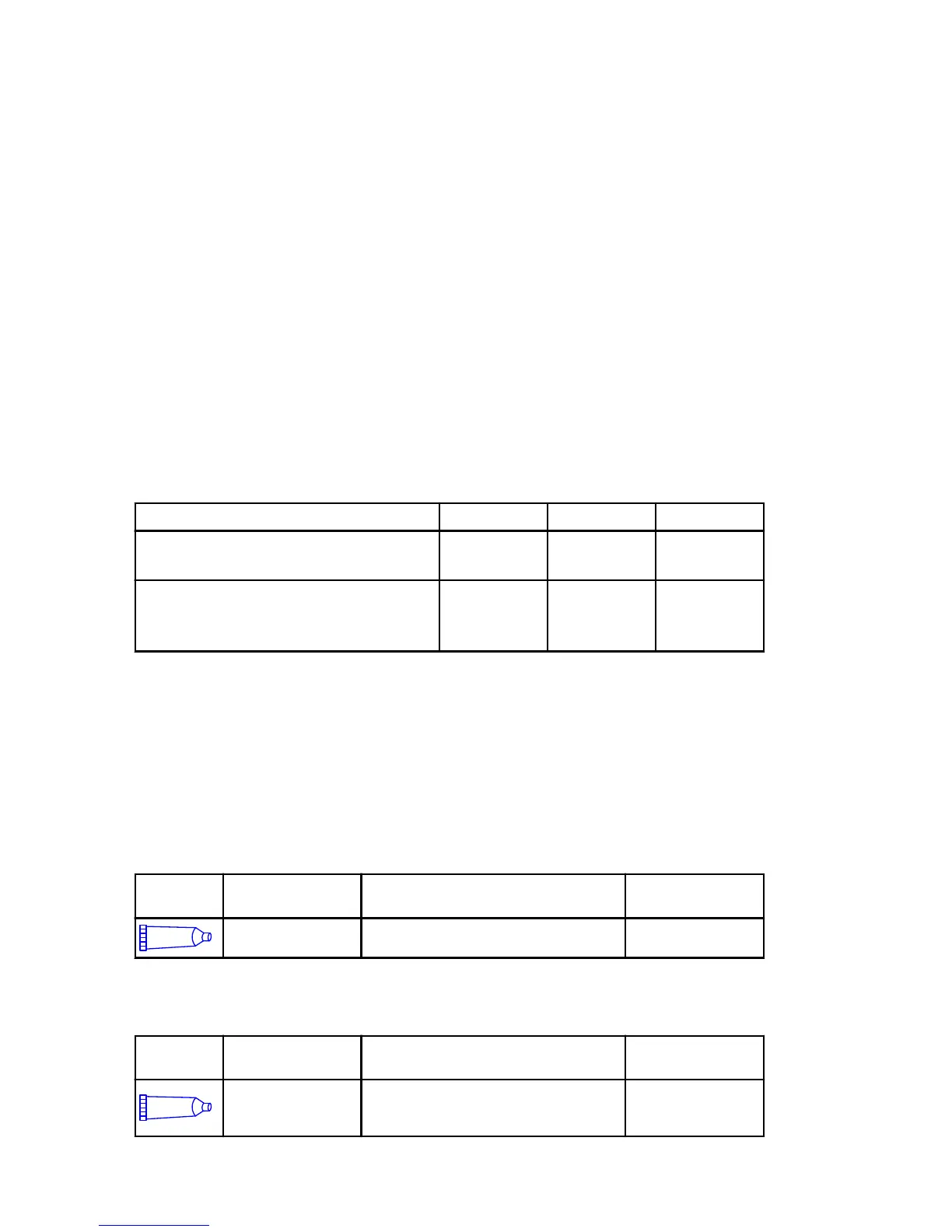

Tube Ref

No.

Description Where Used Part No.

81

Anti-Seize

Compound

Spark plug threads 92-898101389

• Check tightness of bolts, nuts, and other fasteners—dealer service.

• Add Quickleen Engine and Fuel System Cleaner to the fuel tank.

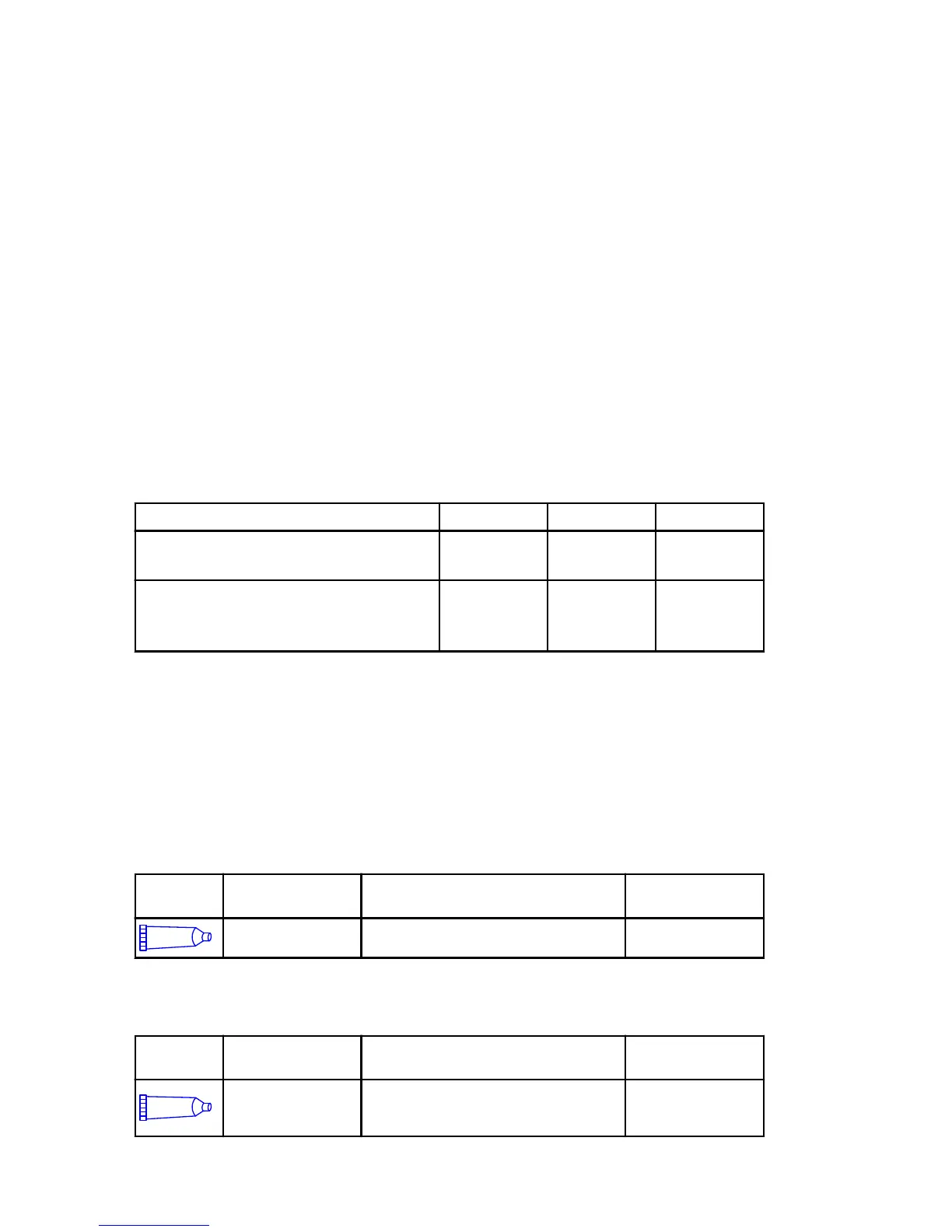

Tube Ref

No.

Description Where Used Part No.

Quickleen Engine &

Fuel System

Cleaner

Fuel tank 8M0047931

MAINTENANCE

50 eng

Loading...

Loading...