CYLINDER BLOCK AND CRANKCASE

Page 4B–22 90-857138R1 MAY 2000

Inspection

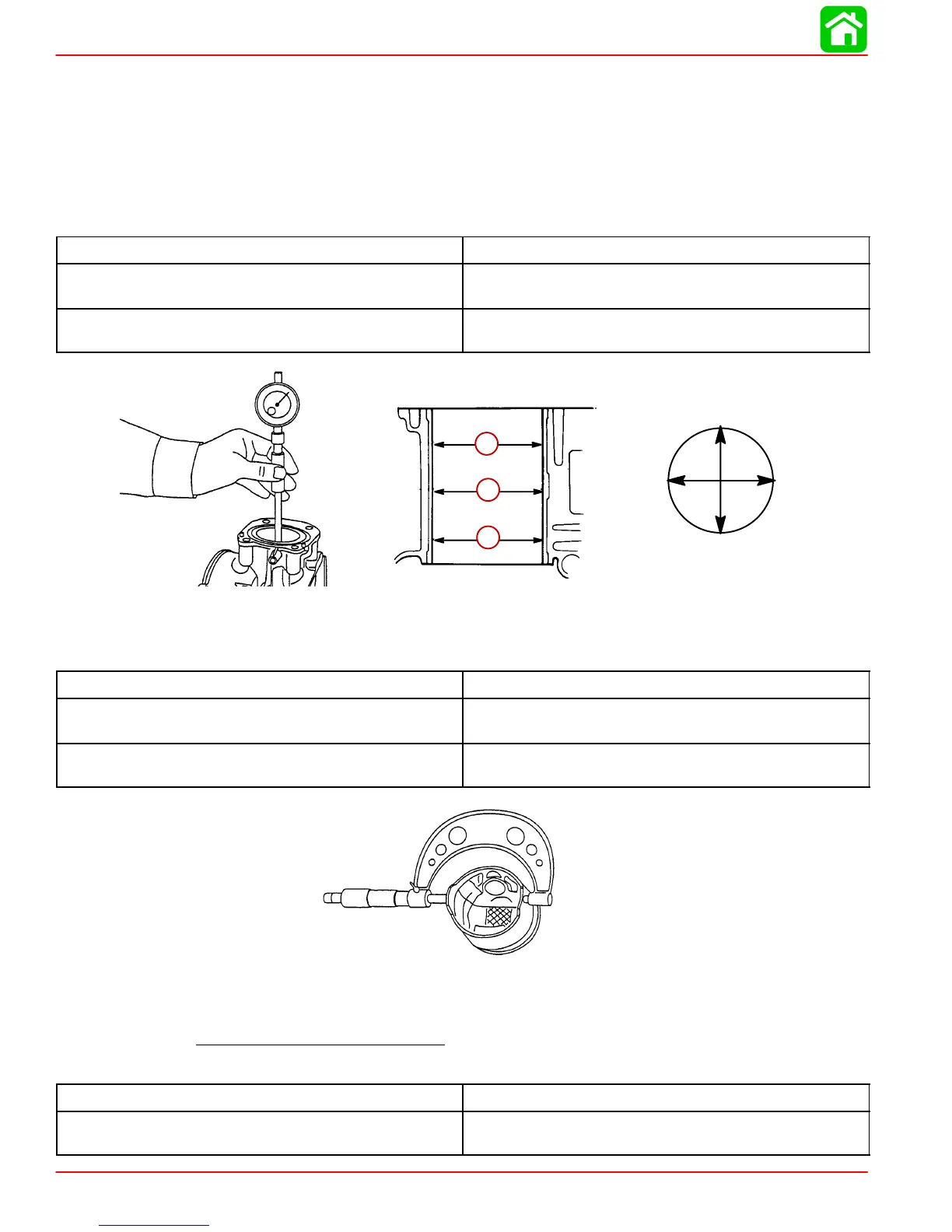

Measuring Cylinder Bore

1. Measure the cylinder bore diameter “d” at three locations in both X and Y axis.

2. If the cylinder bore is beyond the limits listed in the tables below, it will be necessary to

bore or replace the cylinder block.

Standard Value

Out of the Limit

2.323 in. (59.00 mm) If 2.326 in. (59.07 mm) or more, cylinder can be

bored to accept oversize piston

0.020 in. (0.50 mm) Oversize

2.343 in. (59.50 mm)

If 2.345 in. (59.57 mm) or more, cylinder block

needs replacement.

X

Y

d

d

d

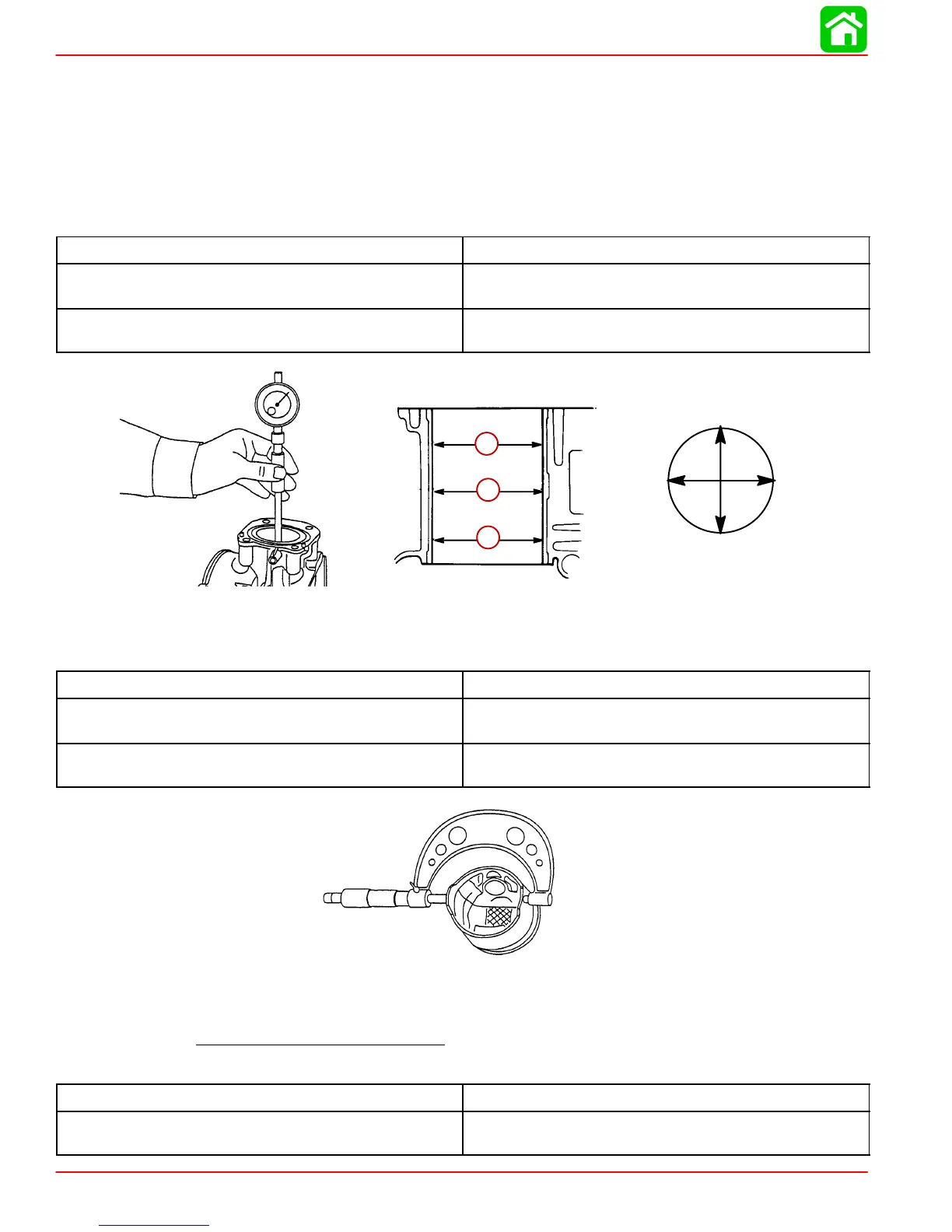

Measuring Diameter of the Piston Skirt

Measure diameter of the piston

Standard Value

Out of the Limit

2.321 in. (58.96 mm) If 2.319 in. (58.90 mm) or less, piston needs

replacement.

0.020 in. (0.50 mm) Oversize

2.341 in. (59.460 mm)

If 2.339 in. (59.40 mm) or more, cylinder block

needs replacement.

Measuring Piston Clearance (Clearance Between Piston and Cylinder)

Minimum cylinder bore measurement

– maximum piston measurement

= piston clearance

Standard Value Out of the Limit

0.001 - 0.002 in. (0.020 – 0.055 mm) If 0.006 in. (0.15 mm) or more, requires

replacement.

Loading...

Loading...