CYLINDER BLOCK AND CRANKCASE

90-857138R1 MAY 2000 Page 4B–31

Powerhead Reassembly

General

Before proceeding with powerhead reassembly, be sure that all parts to be reused have

been carefully cleaned and thoroughly inspected as outlined in “Cleaning and Inspection,”

preceding. Parts, which have not been properly cleaned (or which are questionable), can

severely damage an otherwise perfectly good powerhead within the first few minutes of

operation.

New gaskets MUST BE installed during reassembly.

During reassembly, lubricate parts with Quicksilver 4-Cycle Outboard Oil whenever “light

oil” is specified. Quicksilver part numbers of lubricants, sealers and locking compounds are

listed under “Quicksilver Lubricants and Service Aids,” preceding.

A torque wrench is required for correct reassembly of powerhead. DO NOT attempt to reas-

semble powerhead without using a torque wrench. Attaching bolts for covers and housings

MUST BE torqued by tightening bolts in 3 progressive steps (following specified torque se-

quence) until specified torque is reached. Powerhead torques are listed under “Torque

Specifications,” preceding.

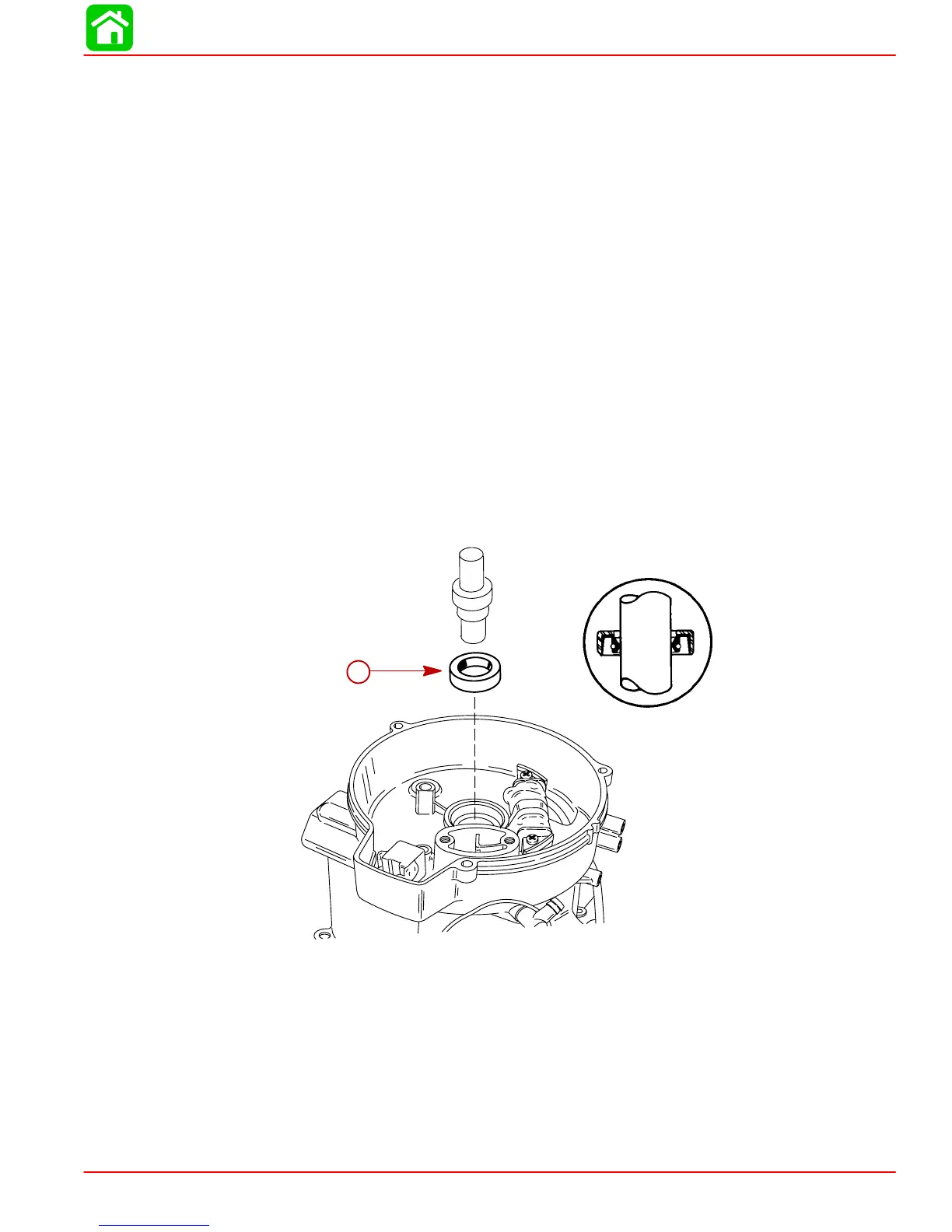

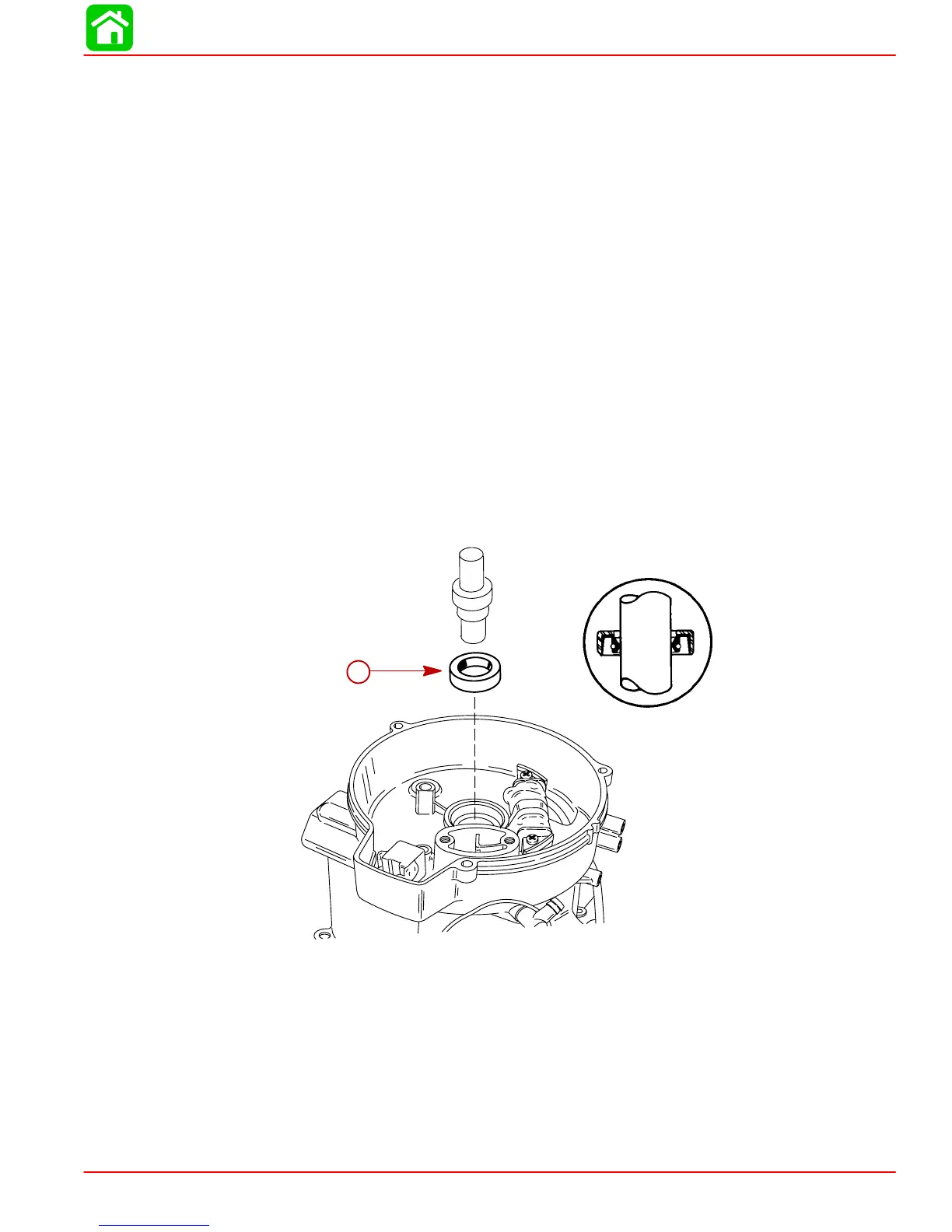

1. Install new oil seal using a suitable mandrel.

a

a-Oil Seal – Press in Until it Bottoms Out

Loading...

Loading...