20

90-10185R30

GB

gof70

1

4

3

2

N

N

of

MAINTENANCE

ohl27

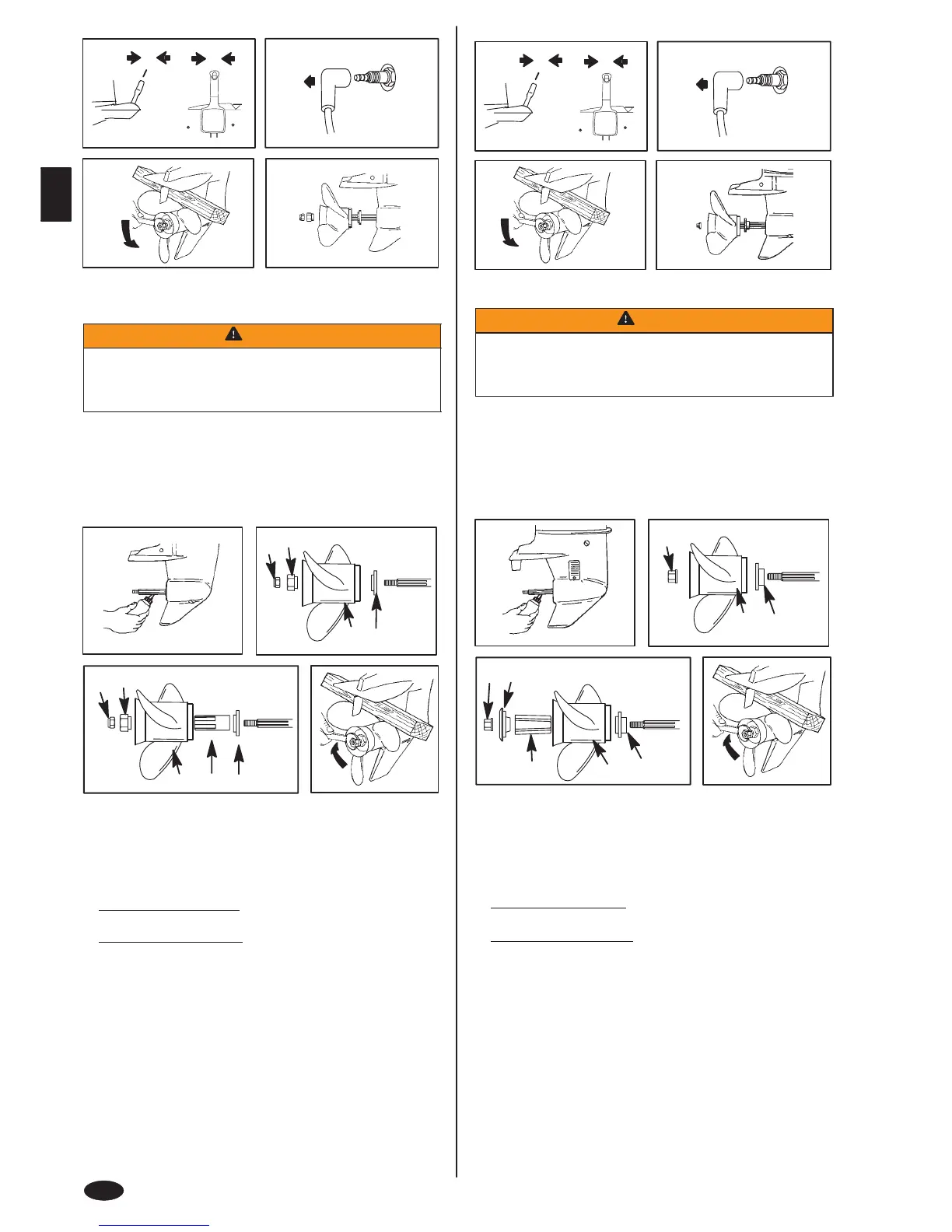

PROPELLER REPLACEMENT - STANDARD MODELS

WARNING

If the propeller shaft is rotated while the engine is in gear, there is the pos-

sibility that the engine will crank over and start. To prevent this type of

accidental engine starting and possible serious injury caused from being

struck by a rotating propeller, always shift outboard to neutral position

and remove spark plug leads when you are servicing the propeller.

1 Shift the outboard to neutral position.

2 Remove the spark plug leads to prevent engine from starting.

3 Place a block of wood between gear case and propeller to hold propeller and

remove propeller nut.

4 Pull propeller straight off shaft. If propeller is seized to the shaft and cannot be

removed, have the propeller removed by an authorized dealer.

gof70

56

8

7

a

c

b

d

e

a

c

b

d

ohl31

PROPELLER REPLACEMENT - STANDARD MODELS

5

Coat the propeller shaft with Quicksilver or Mercury Precision Lubricants

Anti-Corrosion Grease or 2-4-C Marine Lubricant with Teflon.

IMPORTANT: To prevent the propeller hub from corroding and seizing to the

propeller shaft, especially in salt water, always apply a coat of the

recommended lubricant to the entire propeller shaft at the recommended

maintenance intervals and also each time the propeller is removed.

6 Flo-Torq I Drive Hub Propellers - Install forward thrust hub (a), propeller (b),

rear thrust hub (c) and propeller nut (d) onto the shaft.

7 Flo-Torq II Drive Hub Propellers - Install forward thrust hub (a), replaceable

drive sleeve (b) propeller (c), rear thrust hub (d) and propeller nut (e) onto the

shaft.

8 Place a block of wood between gear case and propeller and tighten propeller

nut.

goh88

43

1

2

N

N

ohl29

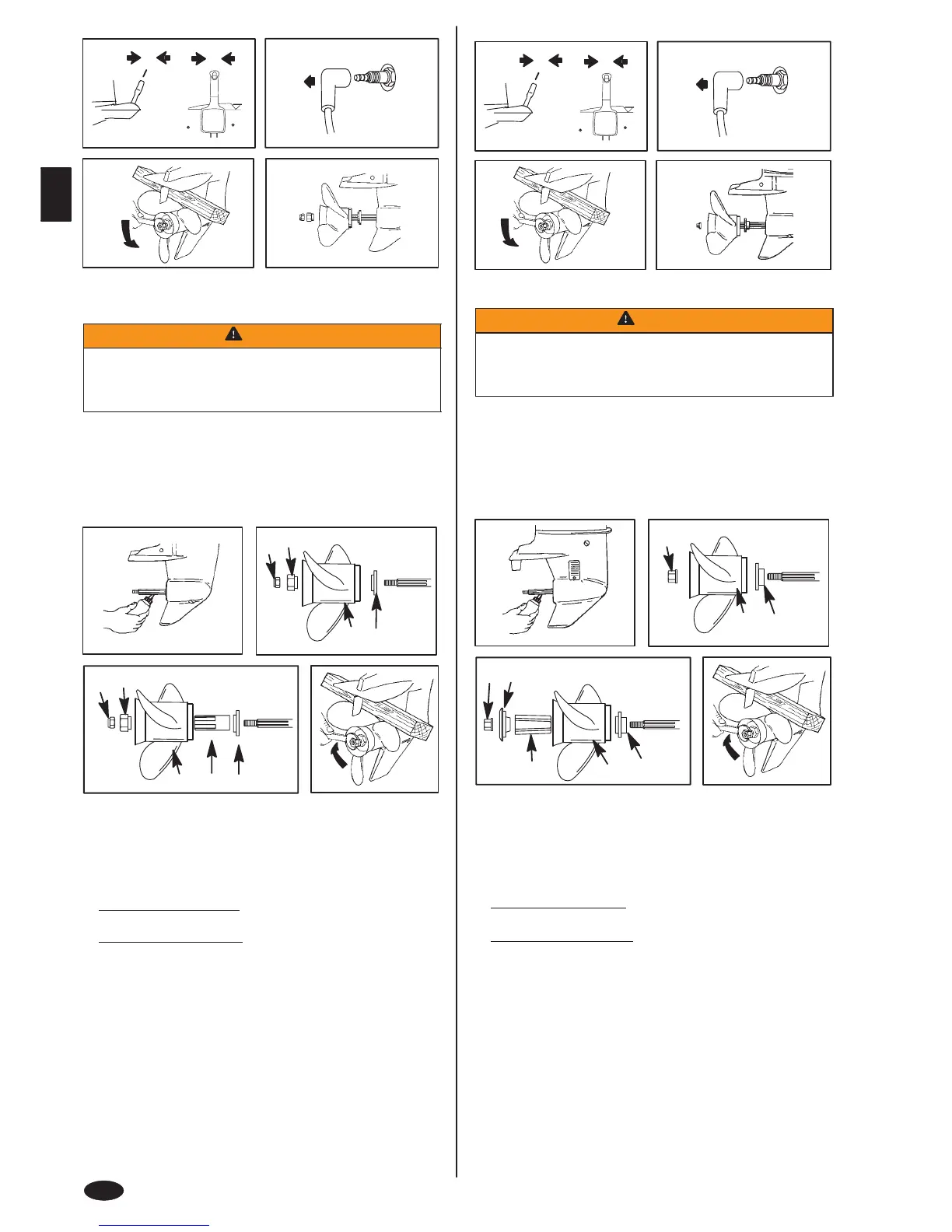

PROPELLER REPLACEMENT - BIGFOOT MODELS

WARNING

If the propeller shaft is rotated while the engine is in gear, there is the pos-

sibility that the engine will crank over and start. To prevent this type of

accidental engine starting and possible serious injury caused from being

struck by a rotating propeller, always shift outboard to neutral position

and remove spark plug leads when you are servicing the propeller.

1 Shift the outboard to neutral position.

2 Remove the spark plug leads to prevent engine from starting.

3 Place a block of wood between gear case and propeller to hold propeller and

remove propeller nut.

4 Pull propeller straight off shaft. If propeller is seized to the shaft and cannot be

removed, have the propeller removed by an authorized dealer.

goh89

56

8

7

a

c

b

e

a

c

b

d

ohl32

PROPELLER REPLACEMENT - BIGFOOT MODELS

5

Coat the propeller shaft with Quicksilver or Mercury Precision Lubricants

Anti-Corrosion Grease or 2-4-C Marine Lubricant with Teflon.

IMPORTANT: To prevent the propeller hub from corroding and seizing to the

propeller shaft, especially in salt water, always apply a coat of the

recommended lubricant to the entire propeller shaft at the recommended

maintenance intervals and also each time the propeller is removed.

6 Flo-Torq I Drive Hub Propellers - Install forward thrust hub (a), propeller (b) and

propeller nut (c) onto the shaft.

7 Flo-Torq II Drive Hub Propellers - Install forward thrust hub (a), propeller (b),

replaceable drive sleeve (c), rear thrust hub (d) and propeller nut (e) onto the

shaft.

8 Place a block of wood between gear case and propeller and tighten propeller

nut.

Loading...

Loading...